Novel slitting wheel

A cutting wheel, a new type of technology, applied in the fields of application, tobacco, and paper cigarette manufacturing, can solve the problems of large vibration, large adsorption force, and unstable equipment performance of the arc ring 3, and achieve the effect of stable rotation and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

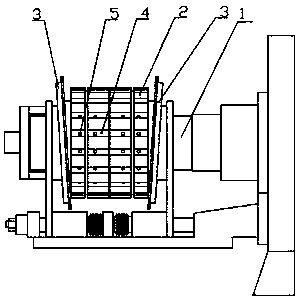

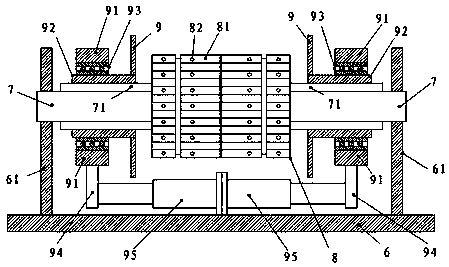

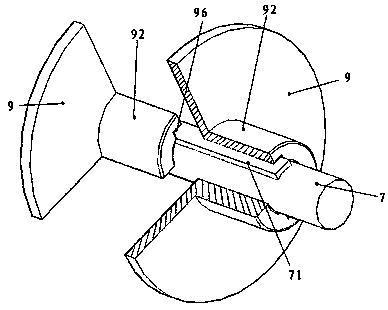

[0023] Refer to attached image 3 And attached figure 2 , a new type of cutting wheel, including a wheel shaft 7, a cutting wheel 8, a cigarette adsorption groove 81 and a negative pressure hole 82, a cutting wheel 8 is fixedly installed in the middle of the wheel shaft 7, and a cigarette adsorption hole is arranged on the cutting wheel 8 Groove 81, cigarette stick adsorption groove 81 is provided with negative pressure hole 82; It also includes base 6, two bearing supports 61, two telescopic cylinders 95, two synchronous sliding sleeves 92, two fixed ferrules 91; The two ends of the wheel shaft 7 are mounted respectively on two bearing supports 61, and the bearing supports 61 are fixedly mounted on the base 6; the wheel shaft 7 is also provided with protruding longitudinal straight bars 71 respectively. Two synchronous sliding sleeves 92 are sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com