Automatic desilting and alarming system for marine silt box

An alarm system and mud box technology, applied in ship construction, ship parts, settlement tanks, etc., can solve problems such as damage to the mud box, poor filtering function of the mud box, etc., to achieve good detection effect, good light transmission, and not easy to deposit. The effect of silt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

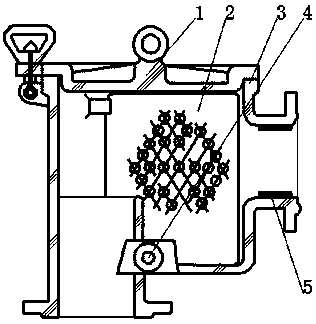

[0038] see figure 1 , an automatic dredging and alarm system for a marine mud box, comprising a mud box body 3, the upper end cover of the mud box body 3 is provided with a cover plate 1, a filter plate 2 is installed inside the mud box body 3, and the lower end of the mud box body 3 is fixedly connected with The water inlet pipe is fixedly connected with the water outlet pipe at the right end of the mud box body 3, the filter plate 2 is located between the water inlet pipe and the water outlet pipe, the outer end of the water inlet pipe is connected with a screw plug 4, and the photosensitive detection device 5 is installed on the inner wall of the water outlet pipe.

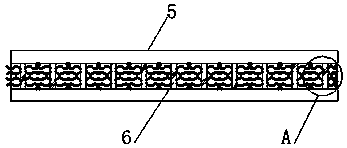

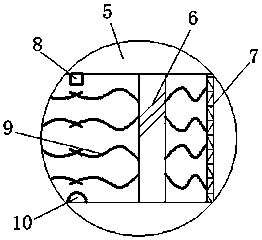

[0039] see figure 2 The interior of the photosensitive detection device 5 is fixedly connected with a plurality of evenly distributed connecting columns 6, and the outer end of the connecting column 6 is connected with a plurality of photosensitive hairs 9, and the surface of the photosensitive hairs 9 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com