Loader transmission case lost foam mold with multi-stair inclined cross runner

A gearbox body, inclined technology, applied in the field of lost foam, can solve the problem that complex castings cannot be completely improved in place, and achieve the effects of reducing removal difficulty, improving thermal balance, and facilitating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

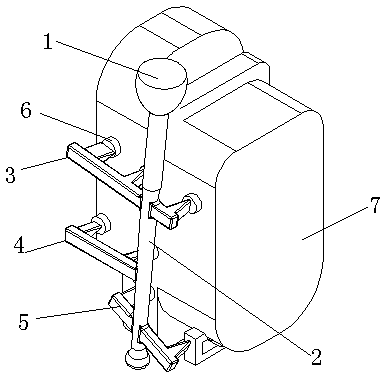

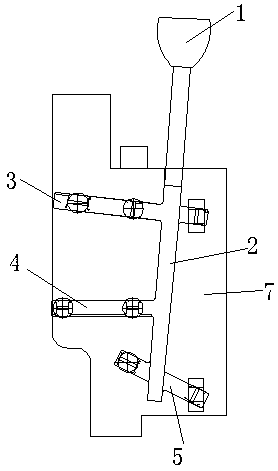

[0019] refer to Figure 1-2 , a loader gearbox body lost foam with multi-layer stepped inclined runners, including a sprue 1, a vertical sprue 2 is fixed on the small side of the sprue 1, and one end of the vertical sprue 2 close to the sprue 1 is fixed There is an oblique runner 3, a horizontal runner 4 is fixed in the middle of the vertical runner 2, an inclined runner 5 is fixed at the end of the vertical runner 2 far away from the sprue 1, an oblique runner 3, a horizontal runner 4, an inclined The bottom of the sprue 5 is fixed with a duckbill-shaped connecting block 6, the bottom of the connecting block 6 is fixed with a gearbox body mold 7, the vertical sprue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com