4000A-electrolytic furnace for producing oxide molten salt through electrolysis

An oxide molten salt and electrolytic furnace technology, which is applied in the field of electrolytic furnaces, can solve problems affecting product quality, poor heat balance of the furnace body, and product quality fluctuations, and achieve the goals of simple furnace building process, cheap and practical price, and improved product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The raw materials for electrolysis are mixed rare earth oxides, and the raw materials are:

[0014] TRE 97% Fe 2 o 3 0.05%

[0015] La 2 o 3 33%-37% SiO 2 0.02%

[0016] CeO 2 44%-48% CaO 0.05%

[0017] PR 11 o 6 4%-5% MgO 0.01%

[0018] Nd 2 o 3 14%-15% Cl - 0.1%

[0019] 1% burn reduction

[0020] The above raw materials were placed in the crucible 4, the electrolytic current was 3800A-4200A, the cell voltage was 9V-11V, and eight 4000A electrolytic furnaces produced a total of 17,280 kg of mixed rare earth metals on the 20th, with each electrolytic furnace producing 4.5 kg of metal per hour on average.

[0021] Table 1 and Table 2 below are the analysis results of mixed metals produced. The analytical data in the table was completed by Chuo Electric Industry Co., Ltd. of Japan.

[0022] The analysis data shows that the average value of the total amount of rare earths in the mixed rare earth metal products produced by the 4000A oxide mol...

Embodiment 2

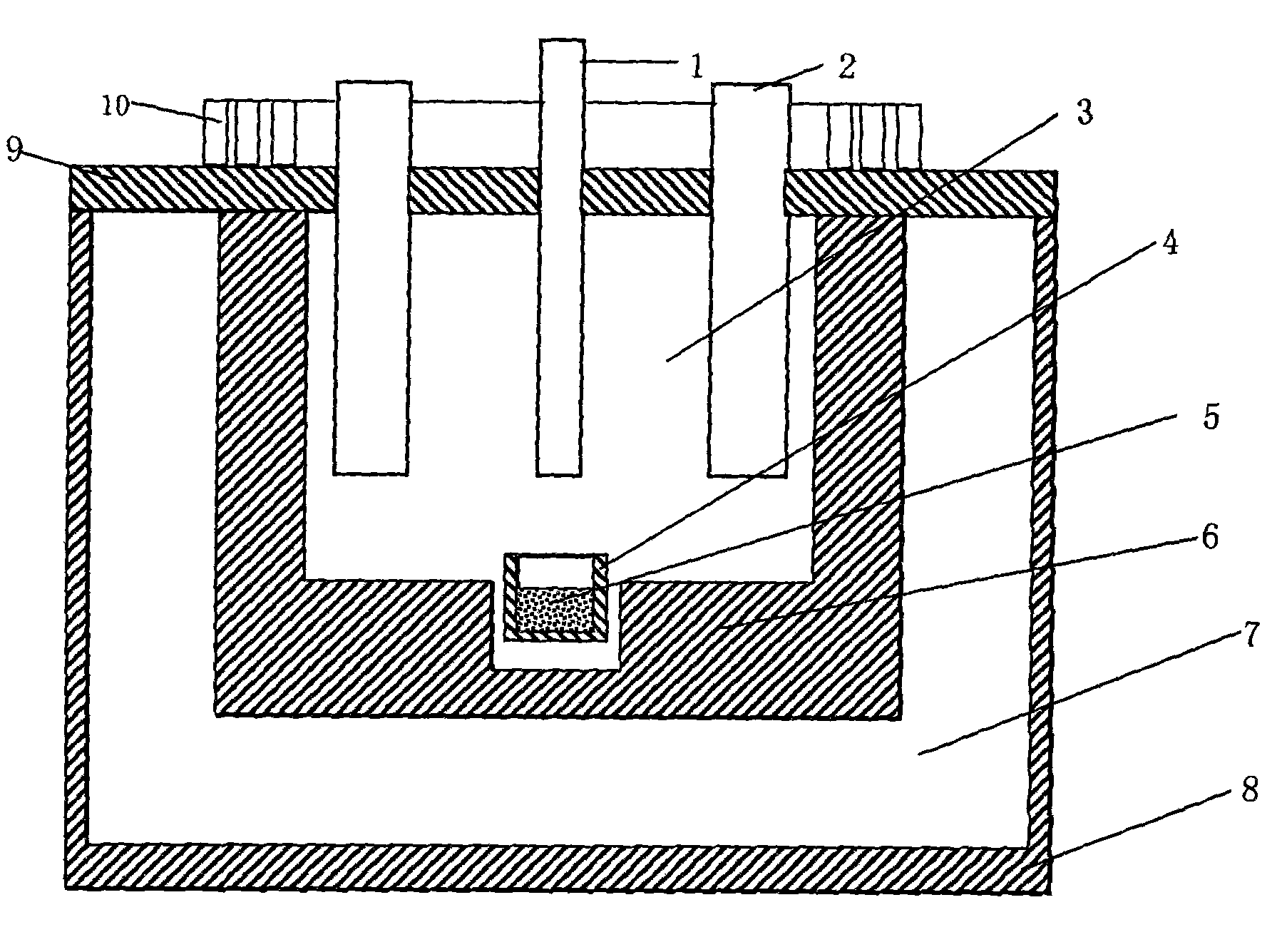

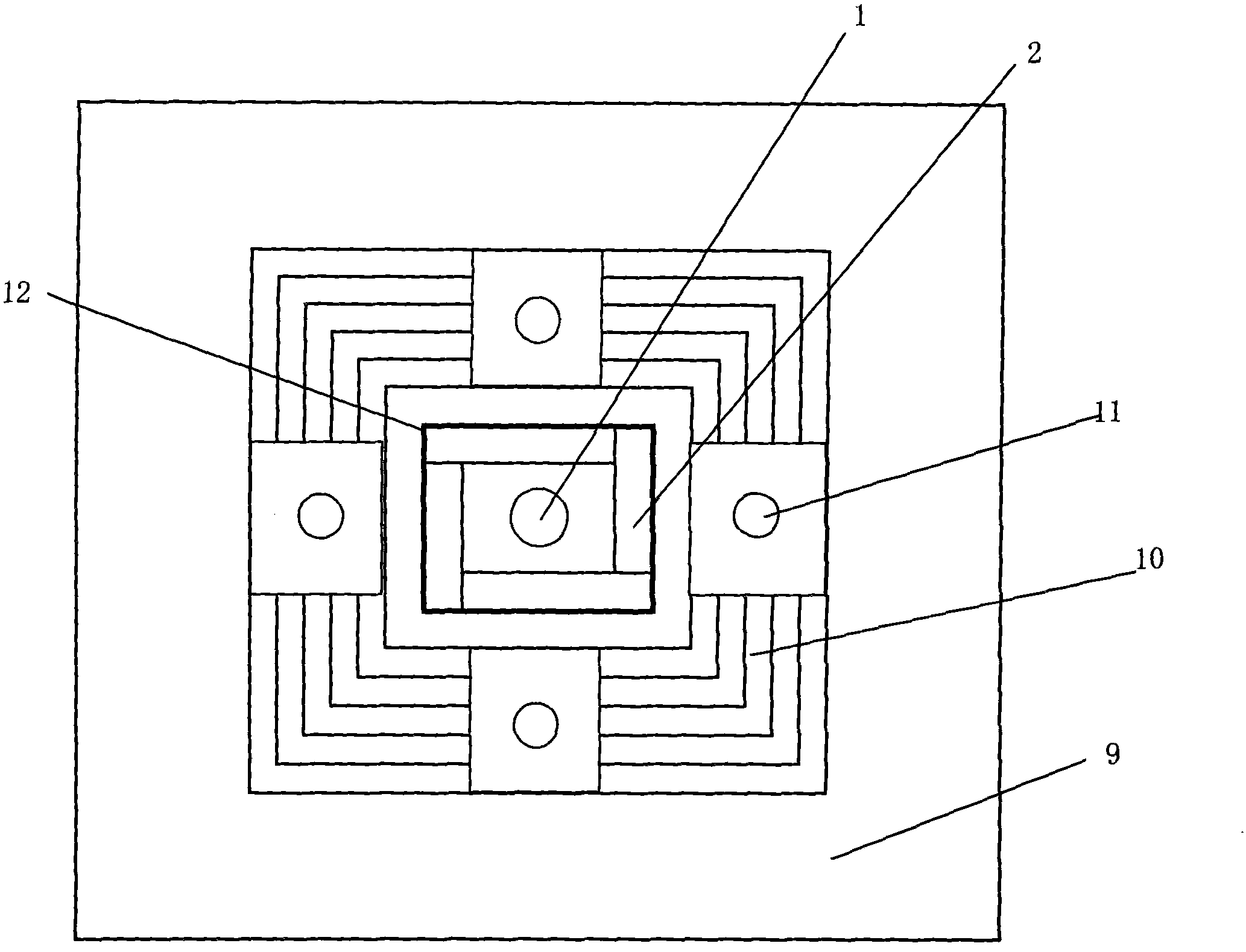

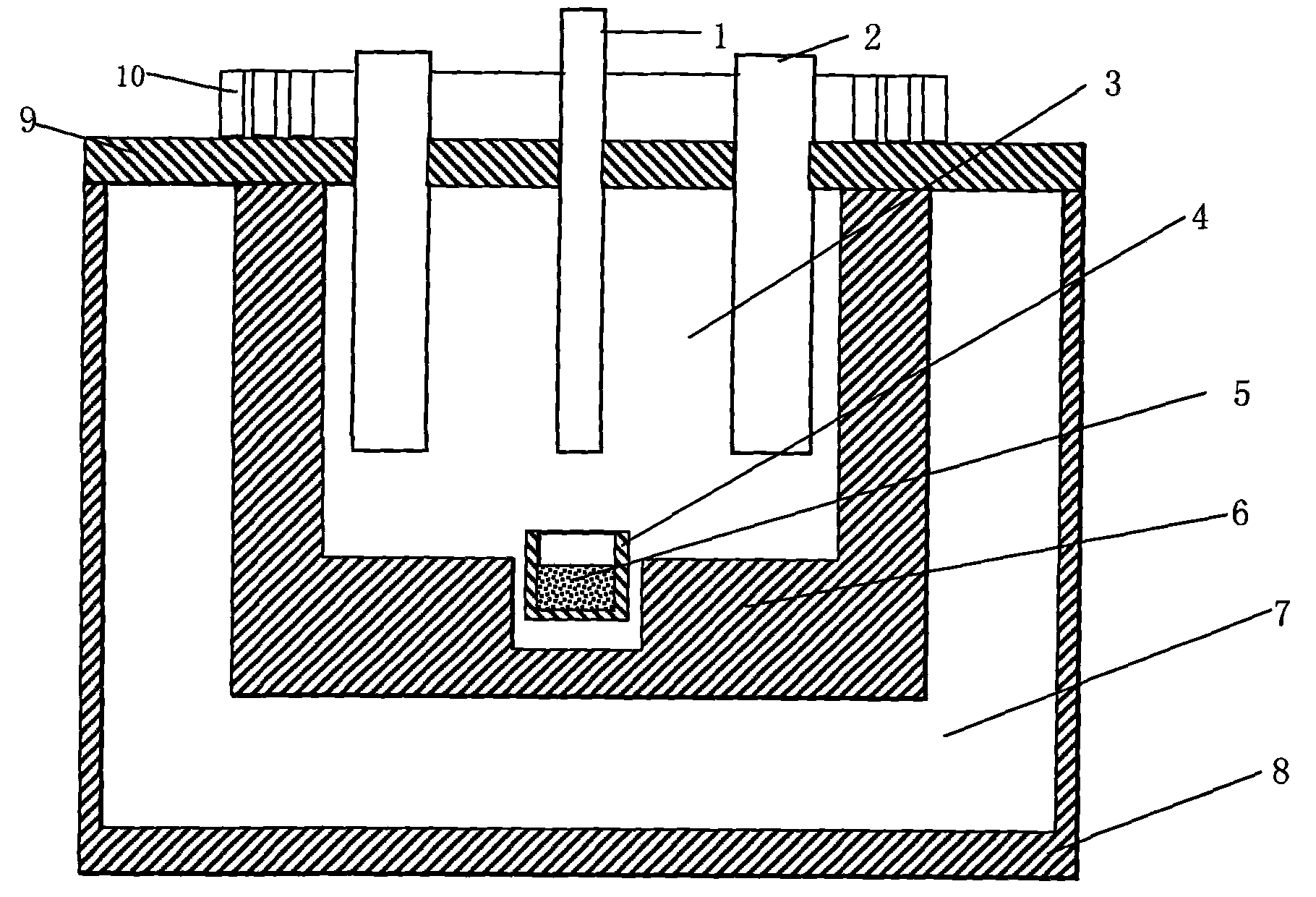

[0023] Embodiment 2 (single rare earth metal neodymium production example):

[0024] The electrolytic cell is manufactured according to the manufacturing method of the 4000A oxide molten salt electrolytic furnace of the present invention, and is composed of a graphite cell, a packing layer, a steel sleeve, a furnace panel, a radiator, a cathode, and an anode. The cathode and anode are placed in the molten salt of the electrolytic furnace, the raw material is a single rare earth neodymium oxide, and the electrolytic molten salt is a single rare earth neodymium fluoride.

[0025] Raw materials: 99%2 o 3 2 6 o 11 <0.05

[0026] 02 o 3 2 <0.02 0

[0027] During production, the electrolysis current is controlled at 4000A-4600A, the cell voltage is 9V-11V, and the electrolysis temperature is controlled at 1020-1080 degrees. For each electrolytic furnace, add raw materials every 5 minutes, 0.5 kg each time. A furnace is produced every 45 minutes, eac...

Embodiment 3

[0031] Embodiment 3 (praseodymium neodymium rare earth alloy production example):

[0032] The electrolytic cell is manufactured according to the manufacturing method of the 4000A oxide molten salt electrolytic furnace of the present invention, and is composed of a graphite cell packing layer, an outer steel jacket, a furnace panel, a radiator, an anode, and a cathode. The cathode and anode are placed in the molten molten salt of the electrolytic furnace, the raw material is mixed praseodymium neodymium rare earth oxide, and the electrolytic molten salt is mixed praseodymium neodymium rare earth fluoride.

[0033] Raw materials: 98.5%2 o 3 2 6 o 11 20%Nd 2 o 3 80%

[0034] Nd 2 o 3 80% 02 o 3 2 <0.02 0

[0035] During production, the electrolysis current is controlled at 4000A-4200A, the cell voltage is 9V-11V, and the electrolysis temperature is controlled at 1000-1040 degrees. For each electrolytic furnace, add raw materials every 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com