Aluminum electrolysis cell forced ventilation afterheat utilization device and utilization method

A technology of forced ventilation and aluminum electrolytic cell, which is applied in the field of waste heat utilization device of forced ventilation of aluminum electrolytic cell, can solve the problems that the electrolytic cell cannot establish a reasonable heat dissipation ratio, insufficient heat preservation, large heat expenditure, unfavorable electrolytic cell, etc., to achieve long-term maintenance Stable and efficient operation, improved energy utilization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

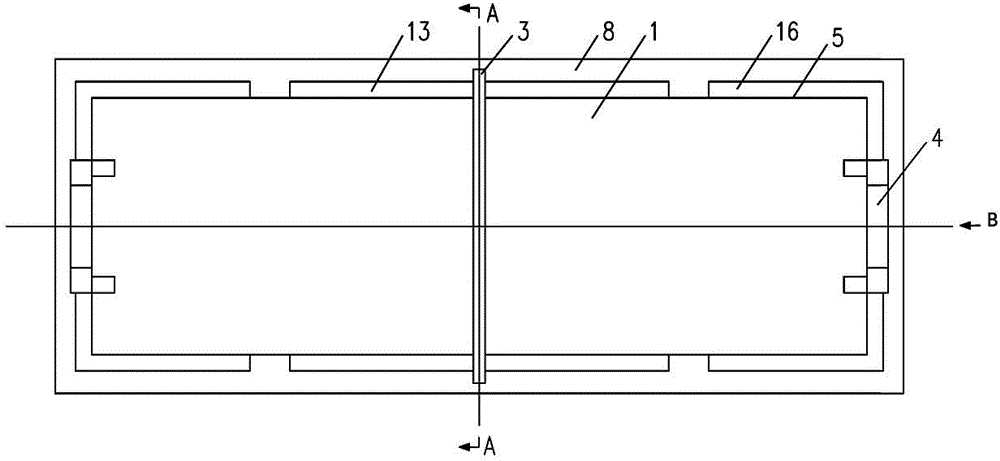

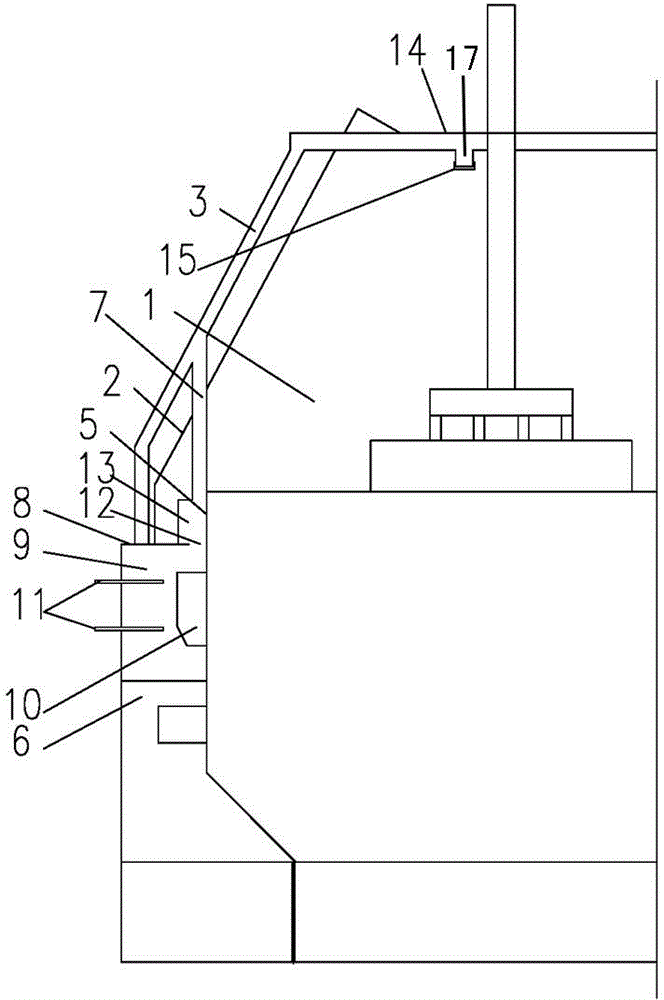

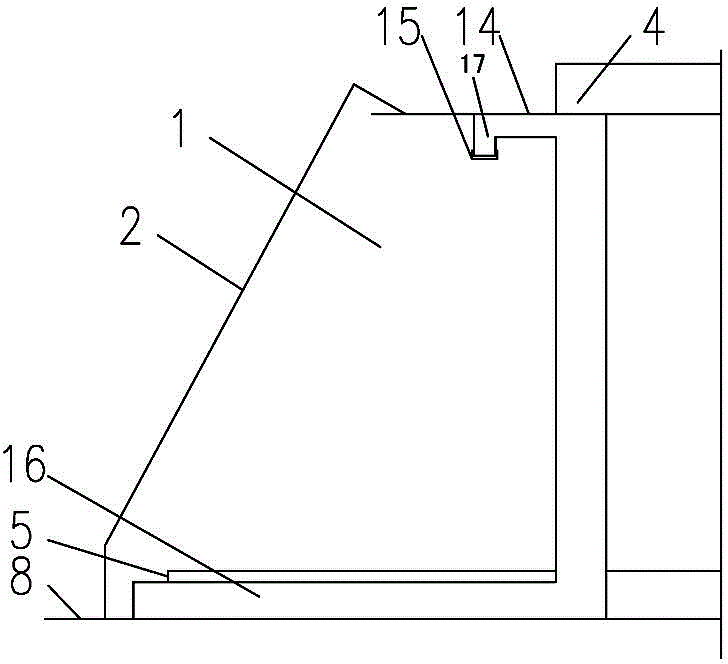

[0031] like Figure 1-3 As shown, the forced ventilation waste heat utilization device of the aluminum electrolytic cell, the tank shell 5 of the electrolytic cell, the cradle frame 6 and the tank edge plate 8 form a forced ventilation sealed box 9, and the radiator plate 10 is welded on the tank shell 5 of the sealed box 9, and the radiator plate 10 is a steel plate, the thickness of the cooling plate is 10-30mm, the air inlet pipe 11 is arranged on the sealed box 9, the air inlet pipe 11 is connected with the blower, and the air outlet 12 is opened on the groove along the plate 8, and the air outlet 12 is connected with the horizontal collection exhaust The pipes are connected, and the horizontal collection exhaust pipe includes a central horizontal collection exhaust pipe 13 and an end horizontal collection exhaust pipe 16; the middle horizontal collection exhaust pipe 13 communicates with the vertical exhaust pipe 7, and the vertical exhaust pipe 7 protrudes The trough cov...

Embodiment 2

[0034] like Figure 4-6 As shown, the forced ventilation waste heat utilization device of the aluminum electrolytic cell, the tank shell 5 of the electrolytic cell, the cradle frame 6 and the tank edge plate 8 form a forced ventilation sealed box 9, and the radiator plate 10 is welded on the tank shell 5 of the sealed box 9, and the radiator plate 10 is a steel plate, the thickness of the cooling plate is 10-30mm, the air inlet pipe 11 is arranged on the sealed box 9, the air inlet pipe 11 is connected with the blower, and the air outlet 12 is opened on the groove along the plate 8, and the air outlet 12 is connected with the horizontal collection exhaust The pipes are communicated, and the horizontal collection exhaust pipeline includes a central horizontal collection exhaust pipeline 13 and an end horizontal collection exhaust pipeline 16; the middle horizontal collection exhaust pipeline 13 and the end horizontal collection exhaust pipeline 16 are connected with the vertical...

Embodiment 3

[0037] In embodiment 1, eight middle horizontal collection and exhaust pipes are arranged in the length direction of the tank shell 5 . Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com