Coating and manufacturing method for aluminum alloy wheel hub, and method for compounding the coating on the wheel hub

A technology of aluminum alloy wheel hub and aluminum alloy powder, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of universality of pollution technology, inappropriate recovery or improvement of surface size and performance, and achieve improved wear resistance and Hardness, uniform and dense composition, and enhanced bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

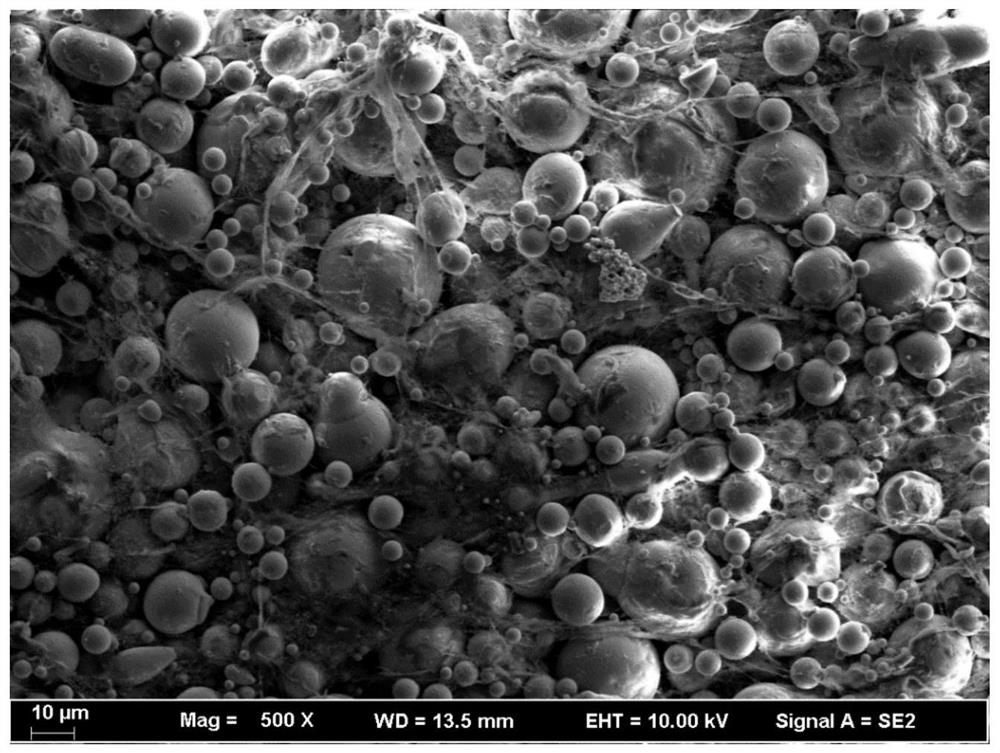

Image

Examples

Embodiment 1

[0023] The coating materials include the following materials: 21% Al-Cu-Ag-Zn powder, 30% Ni-SiC powder, 45% A356 aluminum alloy powder and 4% organic binder. Among them, the organic binder includes the following raw materials: 30.1% tetraethyl orthosilicate, 28.2% methyltriethoxysilane, 6.5% dimethyldiethoxysilane, 5.3% maleic anhydride, 5.0% di Ethylaminopropylamine, 0.8% m-phenylenediamine, 8.8% talc, 9.7% acrylate rubber, 4.4% diethylenetriamine, 1.2% butane tetracarboxylic anhydride.

[0024] The preparation method of coating comprises the steps:

[0025] (1) Take Al-Cu-Ag-Zn powder, Ni-SiC powder and A356 aluminum alloy powder by mass percentage, and mix them;

[0026] (2) Put the mixture into an automatic stirring equipment container, and add an organic binder, then close the container, and stir to obtain a uniform mixture;

[0027] (3) Roll the mixed metal powder particles obtained in step (2) on the automatic roll equipment. First, adjust the distance between the ro...

Embodiment 2

[0037] The coating raw materials include the following raw materials: 23% A-Cu-A-Zn powder, 65% Ni-SiC powder, 10% A356 aluminum alloy powder and 2% organic binder. Wherein, organic binder raw material is identical with embodiment 1.

[0038] The preparation method of coating comprises the steps:

[0039] (1) Take Al-Cu-Ag-Zn powder, Ni-SiC powder and A356 aluminum alloy powder by mass percentage, and mix them;

[0040] (2) Put the mixture into an automatic stirring equipment container, and add an organic binder, then close the container, and stir to obtain a uniform mixture;

[0041] (3) Roll the mixed metal powder particles obtained in step (2) on the automatic roll equipment. First, adjust the distance between the roll and the workbench, control the thickness of the bonding cloth at about 3.0-5.0 mm, and perform preliminary roll forming for 20 minutes. ;

[0042] (4) Roll the adhesive cloth again, adjust the distance between the roller and the workbench again, control th...

Embodiment 3

[0051] Coating raw materials include the following raw materials: 22% A-Cu-Ag powder, 45% Ni-SiC powder, 30% A356 aluminum alloy powder and 3% organic binder. Wherein, organic binder raw material is identical with embodiment 1.

[0052] The preparation method of coating comprises the steps:

[0053] (1) Take Al-Cu-Ag-Zn powder, Ni-SiC powder and A356 aluminum alloy powder by mass percentage, and mix them;

[0054] (2) Put the mixture into an automatic stirring equipment container, and add a silicone resin binder, then close the container, and stir to obtain a uniform mixture;

[0055] (3) Roll the mixed metal powder particles obtained in step (2) on the automatic roll equipment. First, adjust the distance between the roll and the workbench, control the thickness of the bonding cloth at about 3.0-5.0 mm, and perform preliminary roll forming for 15 minutes. ;

[0056] (4) Roll the adhesive cloth again, adjust the distance between the roller and the workbench again, control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com