Switch pure silver contact point hard-rolling tool for ships

A contact and sterling silver technology, which is applied in the field of sterling silver contact rolling hardening tooling for marine switches, can solve the problems of reducing electrical conductivity and thermal conductivity, affecting the reliability and service life of switches, and guaranteeing electrical conductivity and thermal conductivity. rate, improved performance and reliability, consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0047] A marine switch pure silver contact roll-hard tooling, including a bottom plate (sequence 1), an inclined plate (sequence 2), a positioning plate (sequence 3), a support plate (sequence 4), and a rolling wheel (sequence 5).

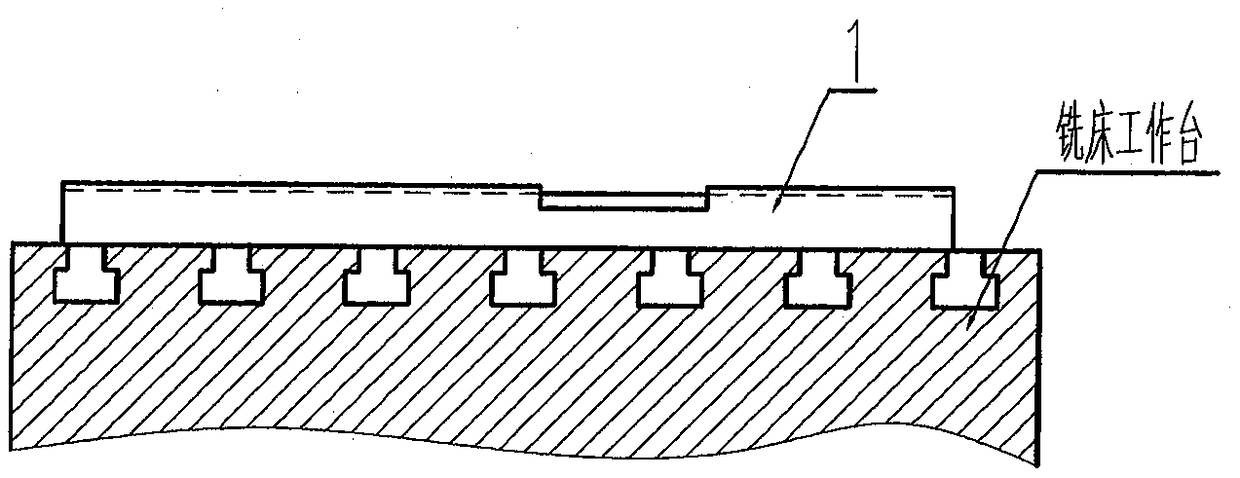

[0048] 1. If figure 1 , fix the bottom plate (sequence 1) on the milling machine table;

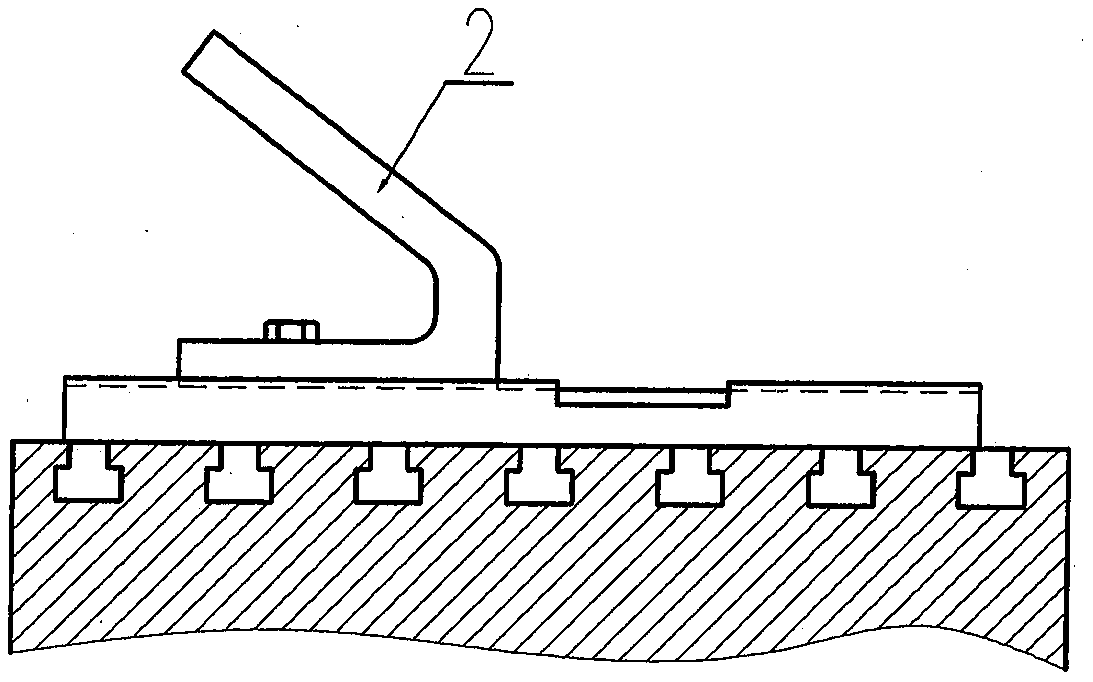

[0049] 2. If figure 2 , place the inclined plate (sequence 2) in the long groove of the bottom plate. like Figure 12 , the corresponding mounting holes of the swash plate are long holes, and the front and rear positions of the swash plate can be adjusted in the long groove of the bottom plate. Adjust the inclined plate to a suitable position and fix it;

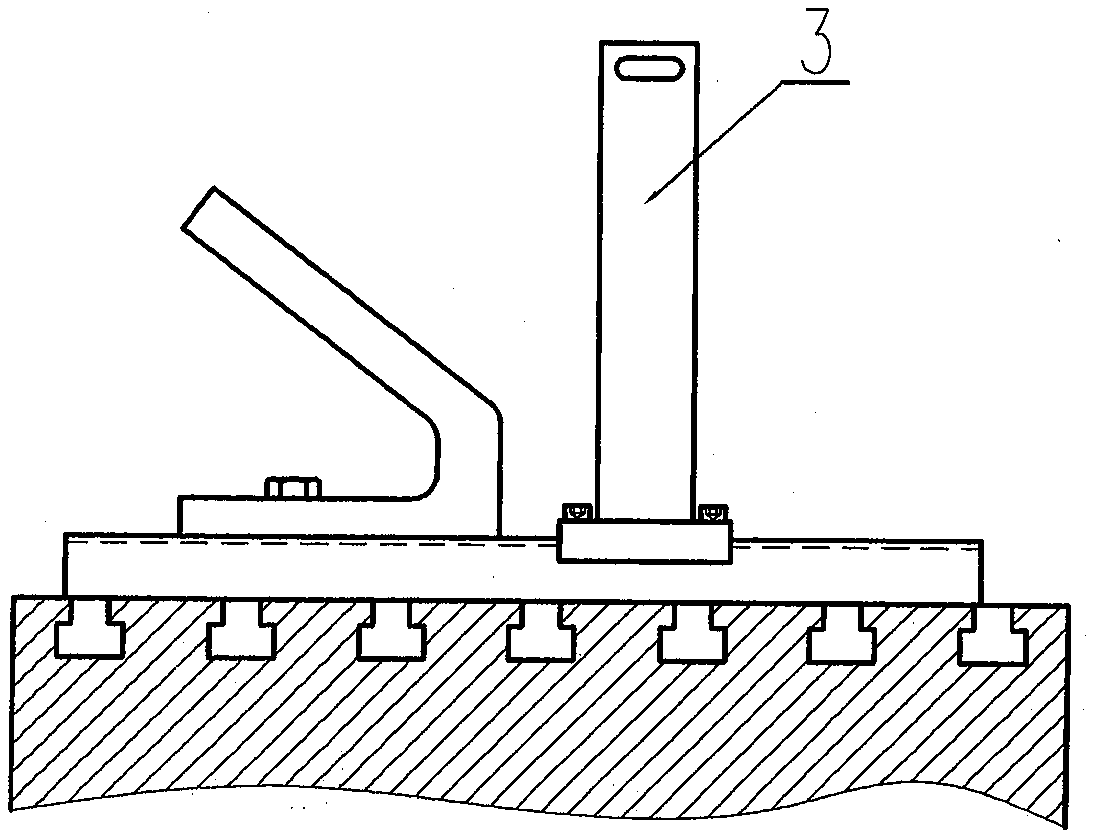

[0050] 3. If image 3 , place a pair of positioning plates (sequence 3) in the short slots of the bottom plate. like Figure 16 , The corresponding mounting holes of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap