Trace management tray of part, assembly unit and tool

A tool and tray technology, applied in the field of protective devices, can solve problems such as loss, chaotic storage, and difficulty in implementing the accountability mechanism, and achieve the effects of saving body space, improving work efficiency, and reducing work errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

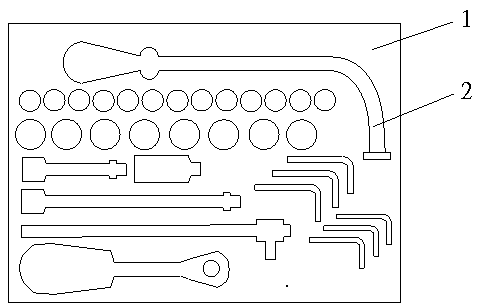

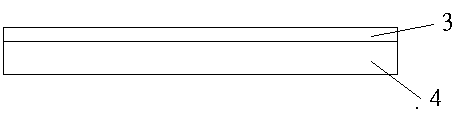

[0022] see figure 1 , figure 2 , a part, component, and tool track management tray includes: a tray body 1, and the tray body 1 is divided into two polymer material forms, one of which is a single-color integrated polymer material, and the other is an upper polymer material. The material and the lower polymer material are composited. The upper polymer material 3 and the lower polymer material 4 have different colors. There are several three-dimensional card slots 2 on the tray body 1 for storing and storing tools. The number of three-dimensional card slots can be customized, based on the principle of saving space and determined according to the number of tools. The thickness of the upper polymer material 3 is 0.5-40 mm, and the thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com