Potting packaging method of fiber-optic hydrophone probe

A fiber optic hydrophone and packaging method technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as fiber damage, fiber stress unevenness, fiber optic hydrophone probe failure, etc. Reliability and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

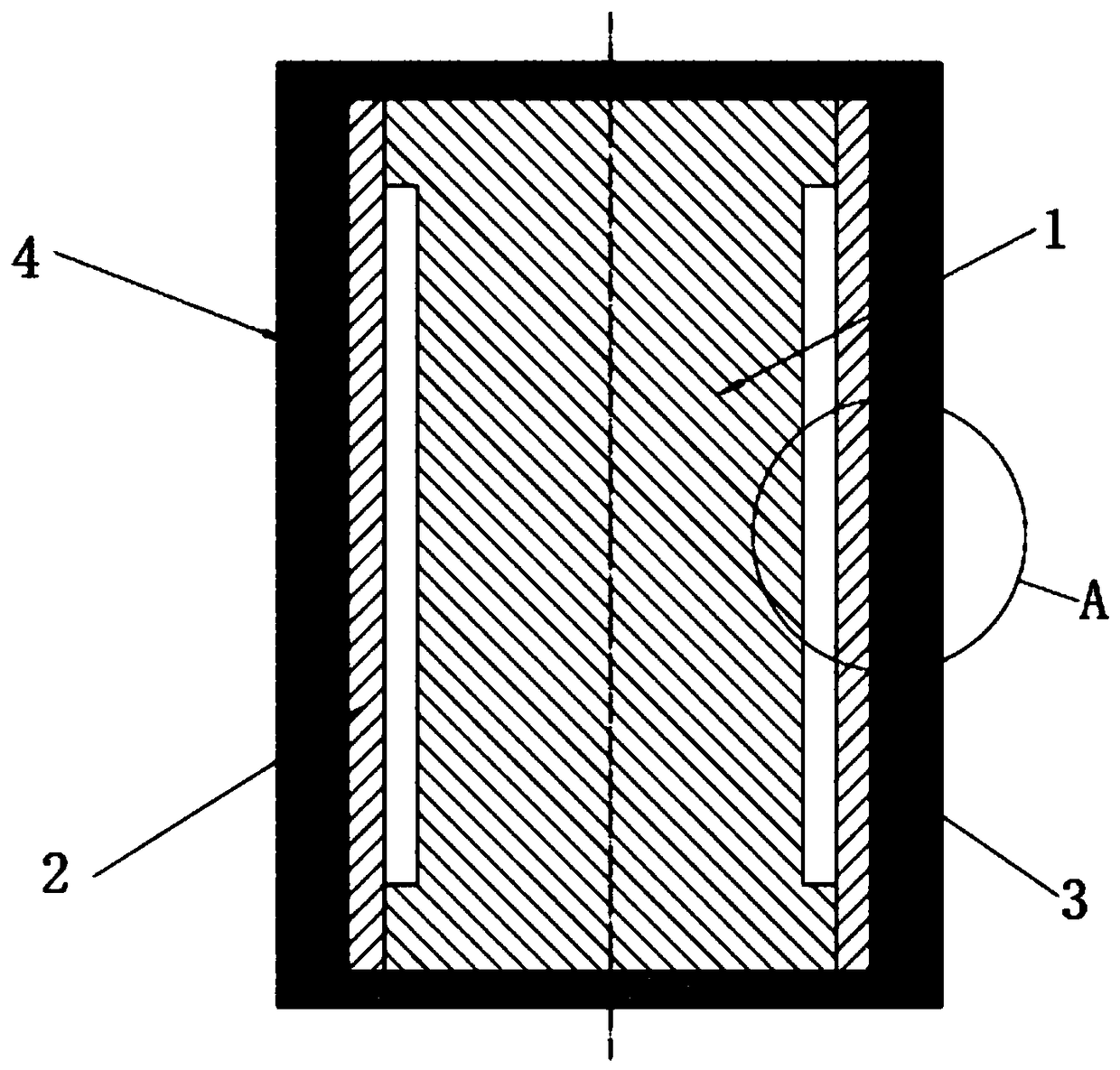

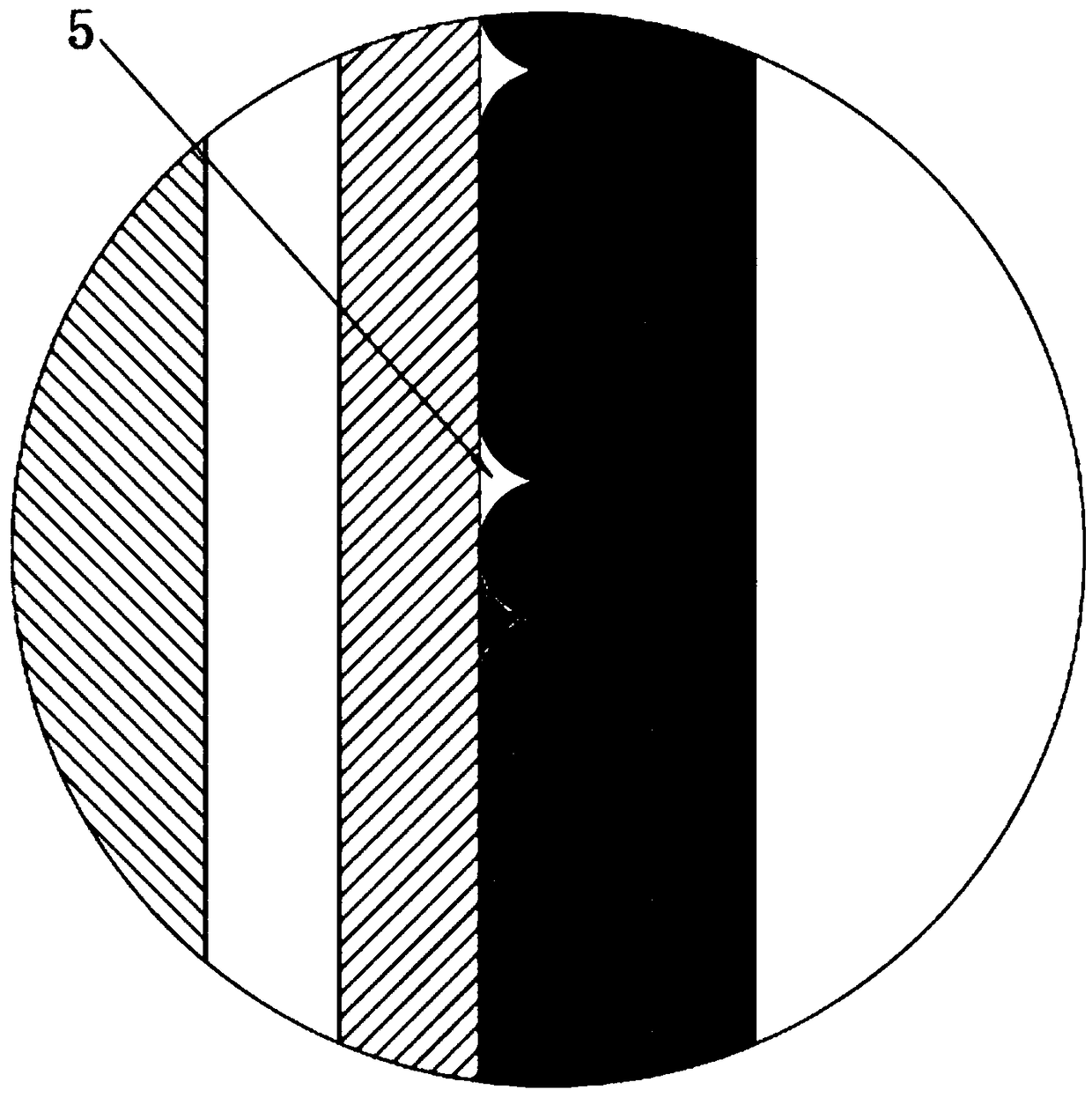

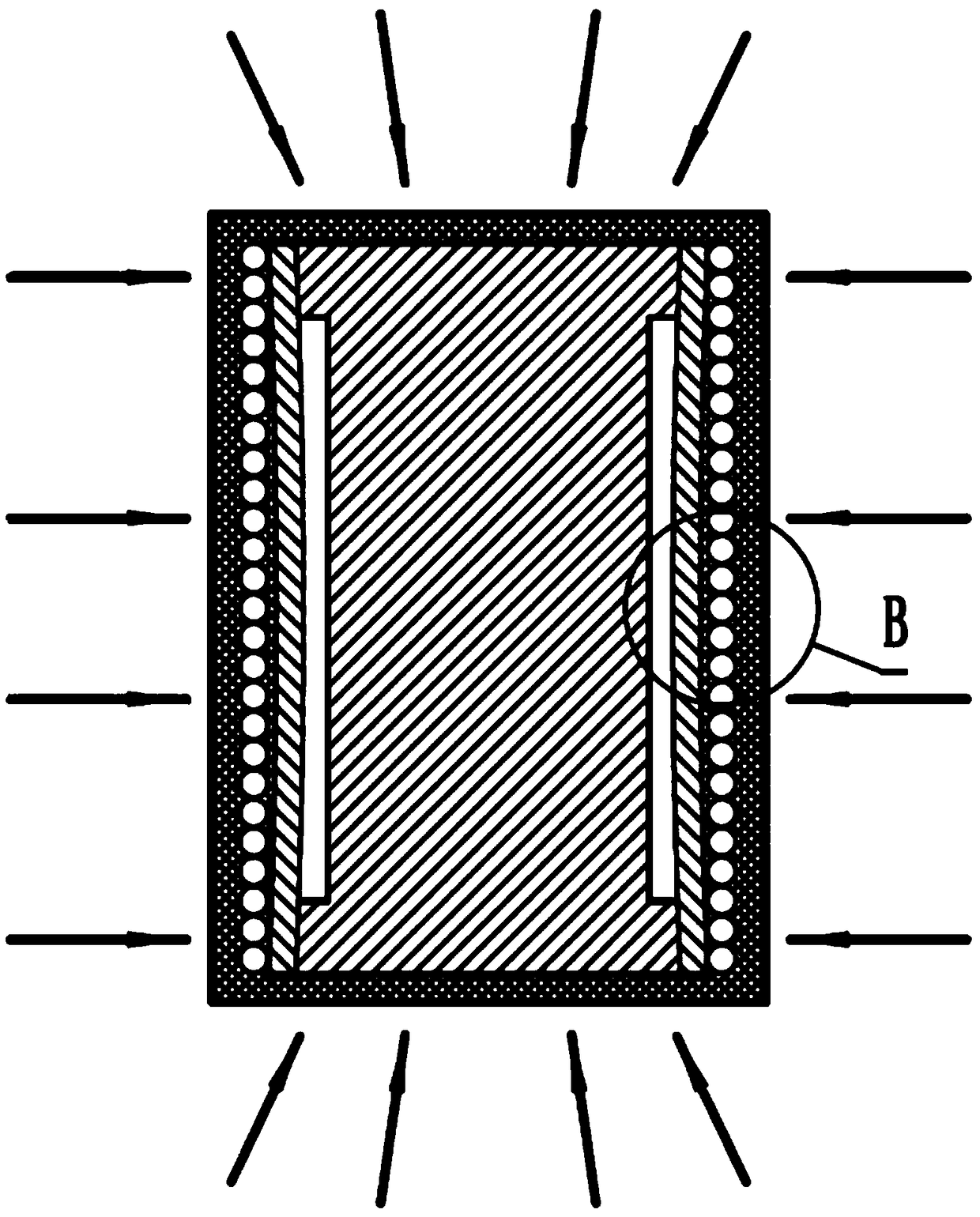

[0029] Specific embodiment: when the sound-transmitting material 4 is polyurethane, and the material of the elastic cylinder 2 is PC, an optical fiber ring is arranged on the outer wall of the elastic cylinder 2 to form an optical fiber ring 3, and the sound-transmitting material 4 is poured under normal pressure. Installed on the exposed surface of the fiber optic ring 3, so that the sound-transmitting material 4 is coated on the exposed surface of the fiber-optic ring 3, and in the uncured state of the sound-transmitting material 4, put the entire fiber optic hydrophone probe into the cavity of the airtight container , seal the airtight container, and then inject high-pressure inert gas into the airtight cavity, so that the pressure in the airtight cavity reaches 1 MPa, and then maintain the pressure for 8 hours, so that the sound-transmitting material 4 can fully enter between the optical fiber ring 3 and the elastic cylinder 2 The sound-transmitting material 4 completely wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com