Honeycomb pre-splicing device and method

A splicing device and honeycomb technology, which is applied in the field of honeycomb manufacturing, can solve problems such as the scrapping of splicing process parts, the decrease of the strength of the splicing position, and the influence of the quality stability of spliced products, so as to achieve low depth of glue shortage in the splicing seam, effective production tasks, and fast splicing. narrow width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

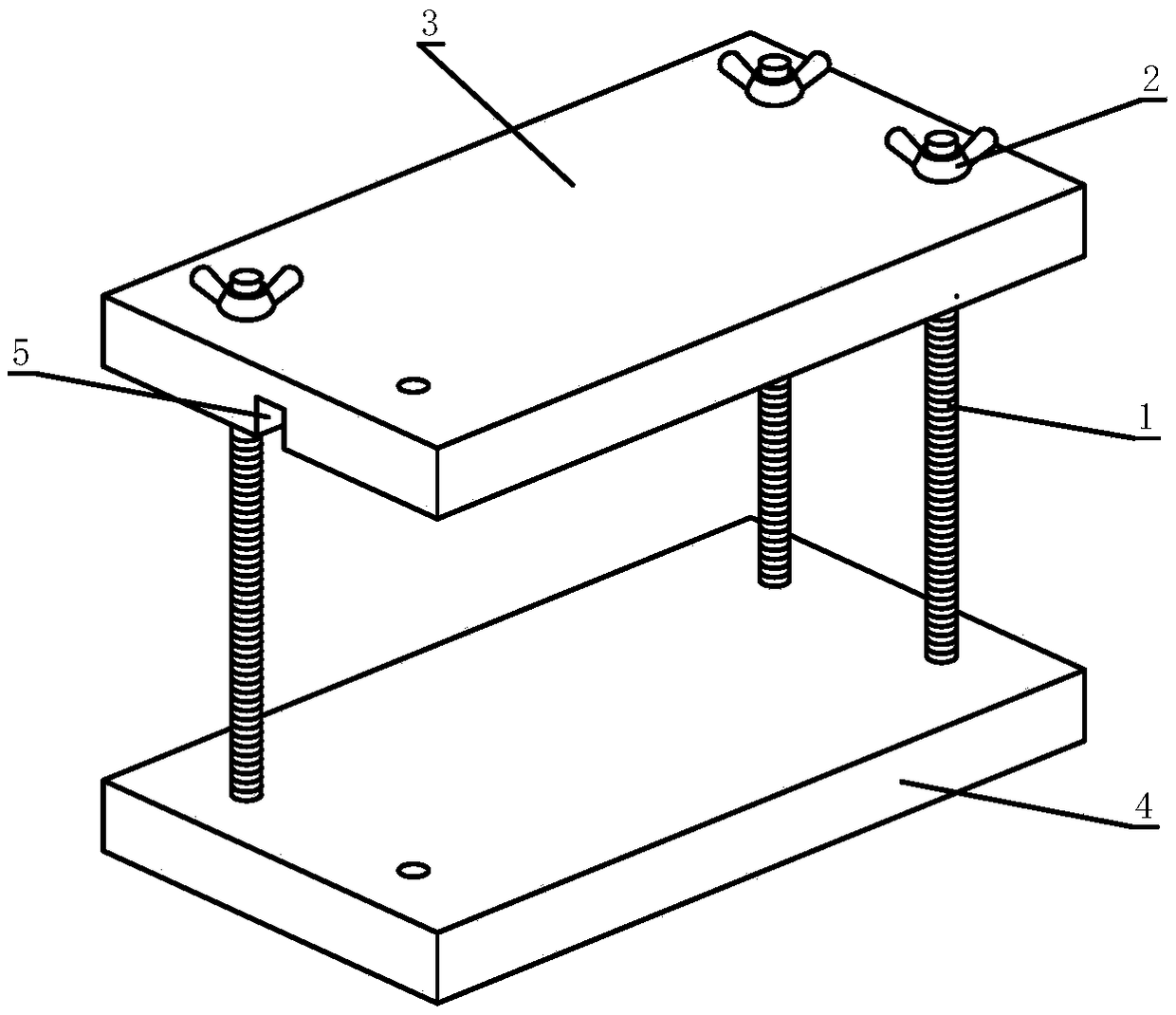

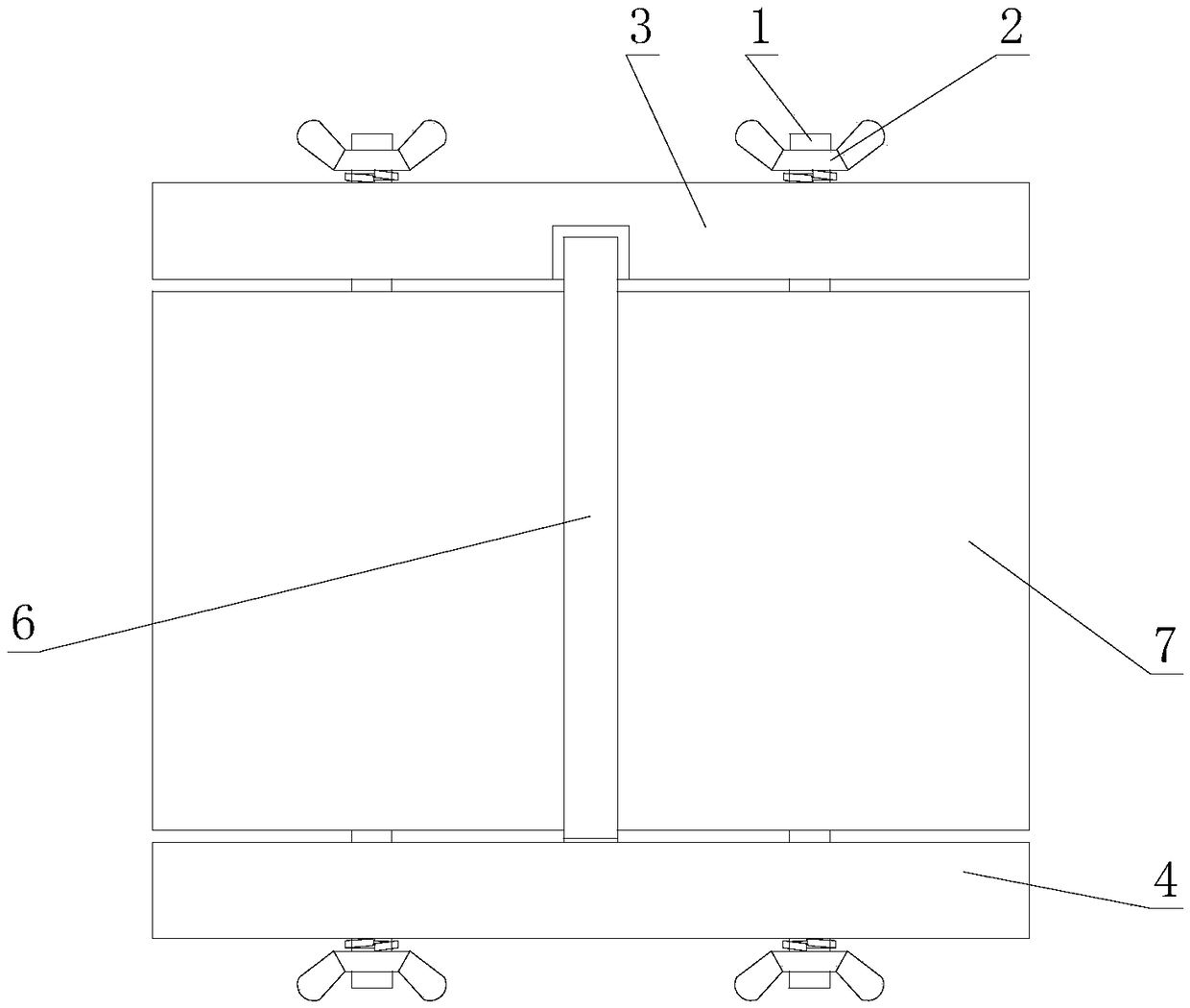

[0022] refer to figure 1 , figure 2 , The pre-splicing tooling for honeycomb splicing disclosed in the present invention is composed of a nut 2, a gasket, an upper plate 3 of a groove fixing plate, a lower plate 4, and a screw 1.

[0023] The tooling of the present invention is used in conjunction with the existing tooling. The plate without grooves is the lower plate 4, and the plate with grooves is the upper plate 3. The position of the groove 5 of the upper plate 3 in the tooling is the position of the gap between the honeycomb cores. 5 The size is customized according to the product requirements, and the PTFE film is pasted to prevent the styrofoam from sticking to the grooved plate during the curing process. The upper plate 3 and the lower plate 4 need to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com