Environment-friendly five-color printing press

A printing machine, environmental protection technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of affecting the occupational health of the staff, the increase of the content of toxic substances, etc., and achieve good purification effect, efficient purification ability, and maintenance of purification ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

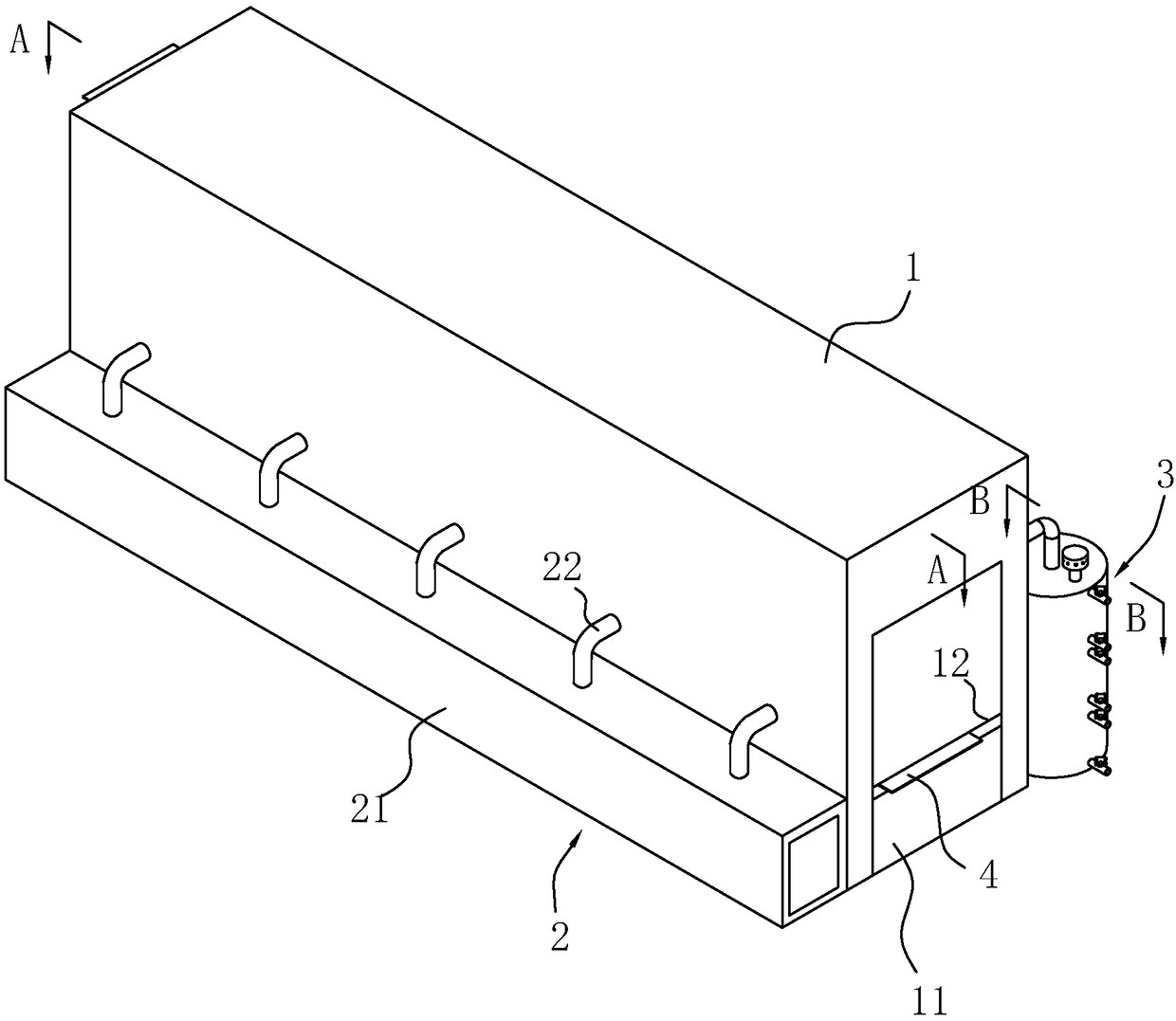

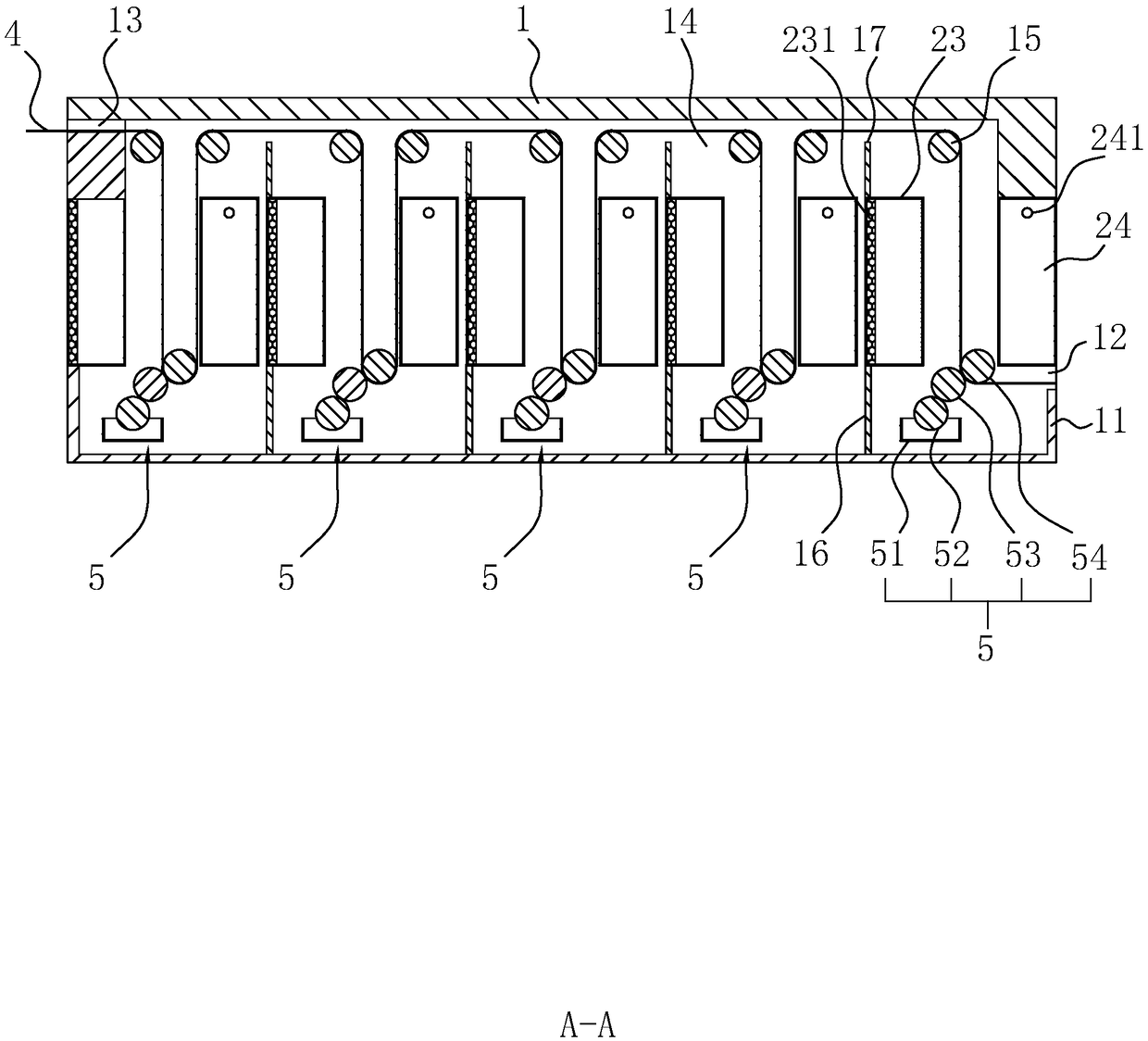

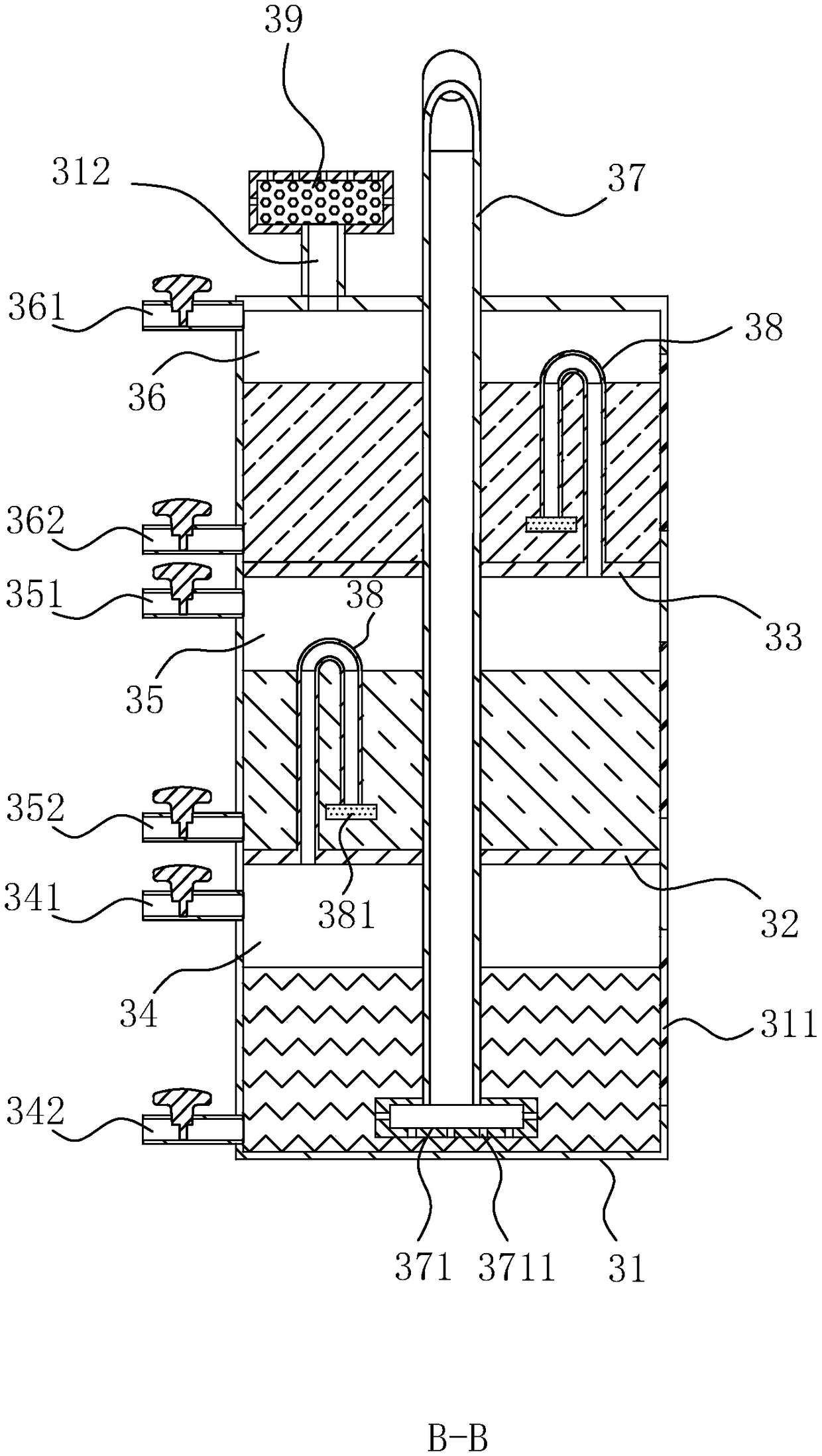

[0035] An environment-friendly five-color printing machine, such as figure 1 and figure 2 As shown, the body 1 is included, and five sets of printing mechanisms 5 are sequentially arranged inside the body 1 along the conveying direction of the printing paper 4 , and the body 1 is connected with a drying mechanism 2 and an air purification mechanism 3 . When the printing paper 4 passes through five sets of printing units 5, each printing unit 5 prints characters or patterns of one color on the printing paper 4, the drying unit 2 dries the ink, and the air cleaning unit 3 dries the air inside the machine body 1. Extracted and purified to clean the air exhausted into the workplace.

[0036] refer to figure 1 and figure 2 , one end of the body 1 is provided with a transmission inlet 12, and the other end of the body 1 is provided with a transmission outlet 13, and a sealing plate 11 is fixed near the transmission inlet 12 and the transmission outlet 13, so that the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com