Adjustable type discharging cloth applied to production of high-frequency transformer

A high-frequency transformer and discharge cloth technology, which is applied in the direction of transportation, packaging, and slideway, can solve the problems of component drop, trouble, and inconvenient use and storage of discharge cloth, so as to prevent falling and use conveniently quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

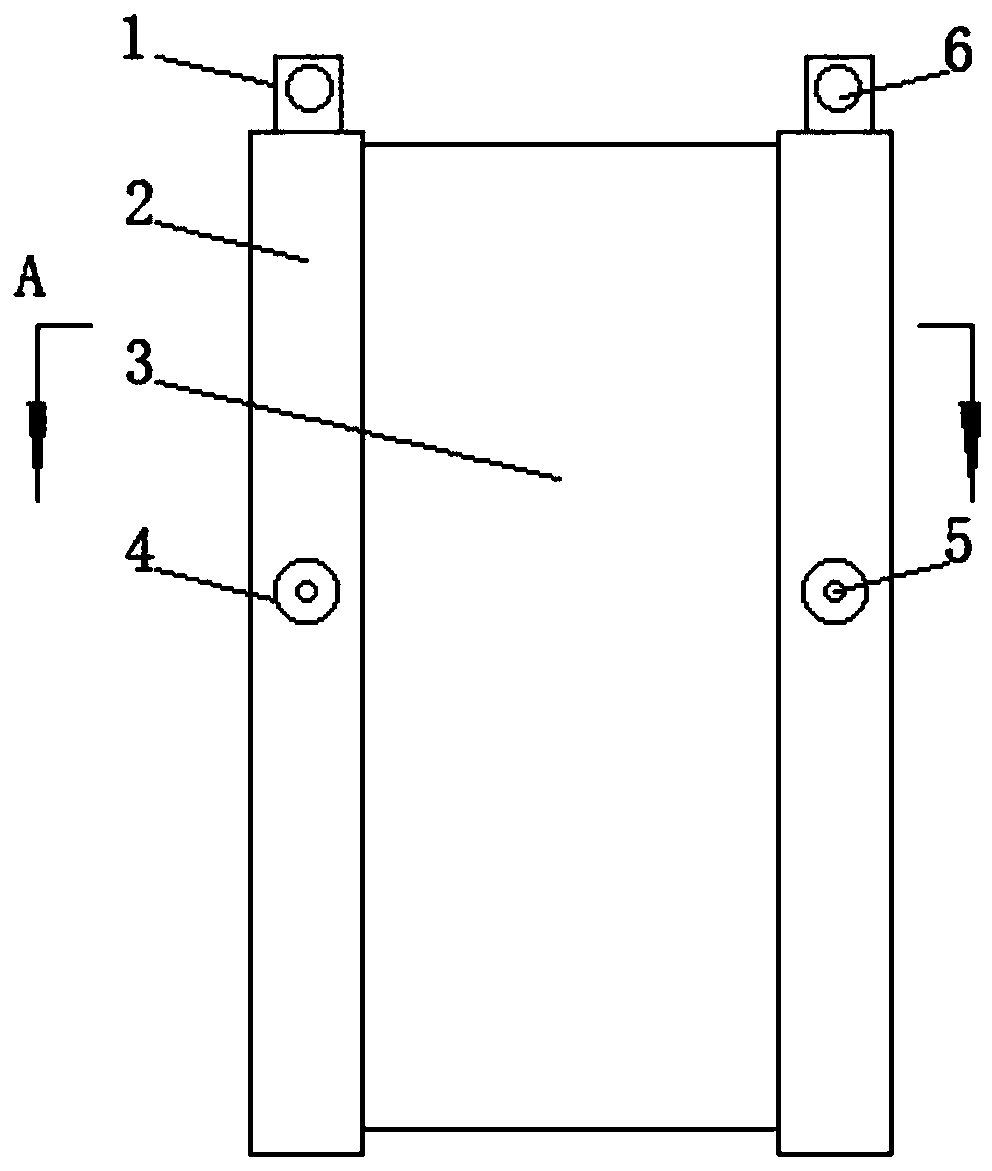

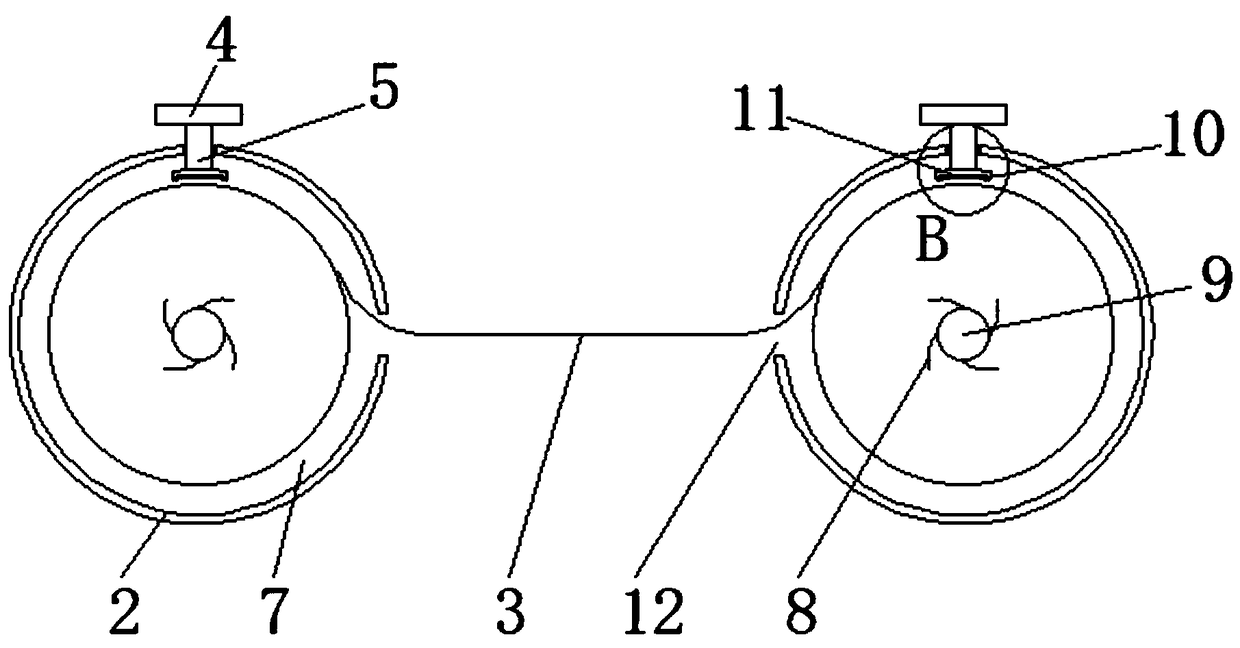

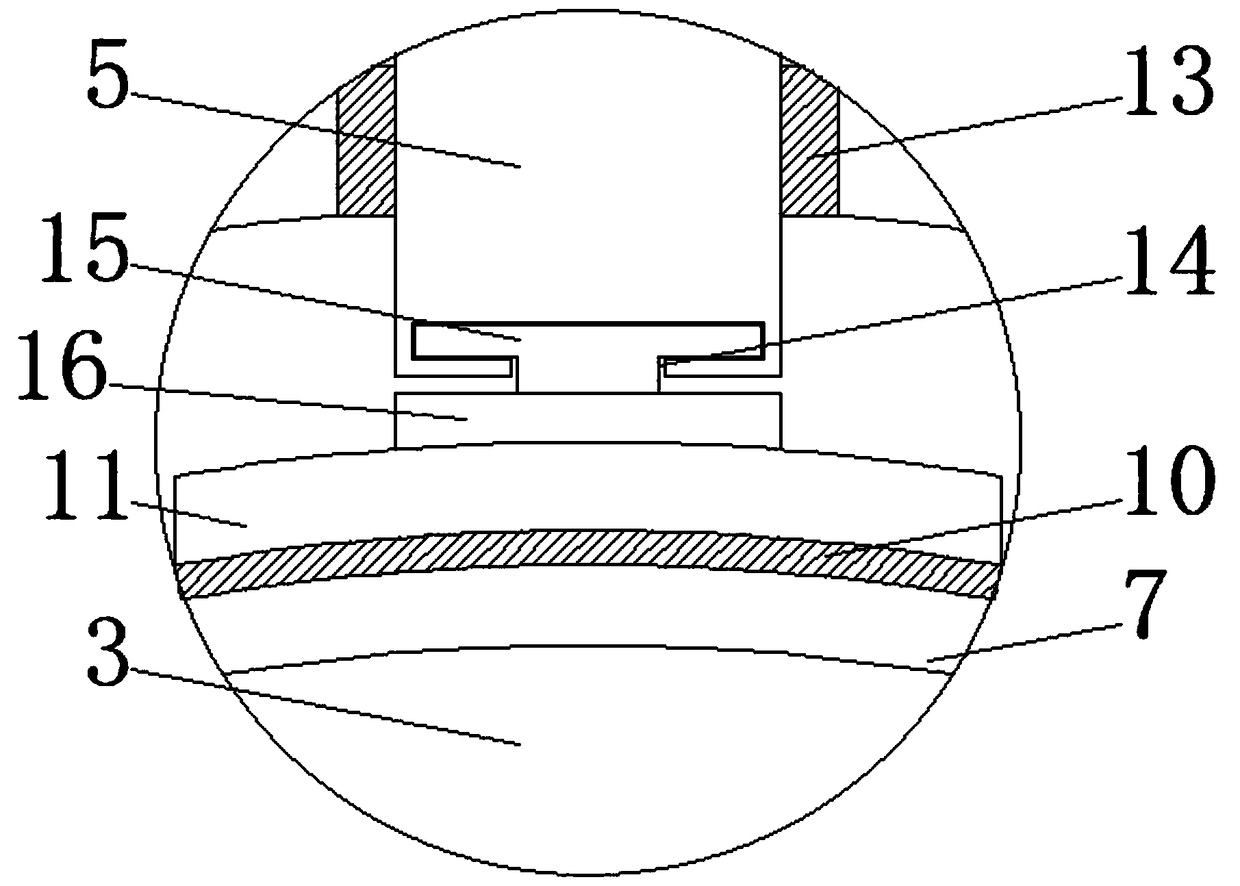

[0016] Embodiment 1, an adjustable discharge cloth for high-frequency transformer production, including a discharge cloth 3, a discharge pipe 2 is provided at both ends of the discharge cloth 3, and an adjustment groove is provided on the inner side of the discharge pipe 2 7. One side of the adjusting groove 7 is provided with a connecting groove 12, and the adjusting groove 7 is provided with a movable shaft 9, the rotating shaft 9 is provided with a ruler spring 8, and the two ends of the discharge cloth 3 are worn. The connecting grooves 12 at both ends of the discharge cloth 3 are evenly wound and connected with the rotating shaft 9 through the ruler spring 8. The middle part of the discharge pipe 2 is provided with a threaded adjustment hole 13, and the threaded adjustment hole 13 is provided with an adjustment shaft 5. The upper end of the adjustment shaft 5 is provided with an adjustment dial 4, and the bottom of the adjustment shaft 5 is provided with a fixed block 11, ...

Embodiment 2

[0019] Embodiment 2, an adjustable discharge cloth for high-frequency transformer production, including a discharge cloth 3, a discharge pipe 2 is provided at both ends of the discharge cloth 3, and an adjustment groove is provided on the inner side of the discharge pipe 2 7. One side of the adjusting groove 7 is provided with a connecting groove 12, and the adjusting groove 7 is provided with a movable shaft 9, the rotating shaft 9 is provided with a ruler spring 8, and the two ends of the discharge cloth 3 are worn. The connecting grooves 12 at both ends of the discharge cloth 3 are evenly wound and connected with the rotating shaft 9 through the ruler spring 8. The middle part of the discharge pipe 2 is provided with a threaded adjustment hole 13, and the threaded adjustment hole 13 is provided with an adjustment shaft 5. The upper end of the adjustment shaft 5 is provided with an adjustment dial 4, and the bottom of the adjustment shaft 5 is provided with a fixed block 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com