Self-driven guide rail trolley suitable for curve guide rail

A curved guide rail and self-driven technology, which is applied in the field of guide rail transmission, can solve the problems of increasing system production cost, increasing system complexity, and complex structure of the transmission mechanism, so as to facilitate daily maintenance and repair, facilitate overall miniaturization, and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

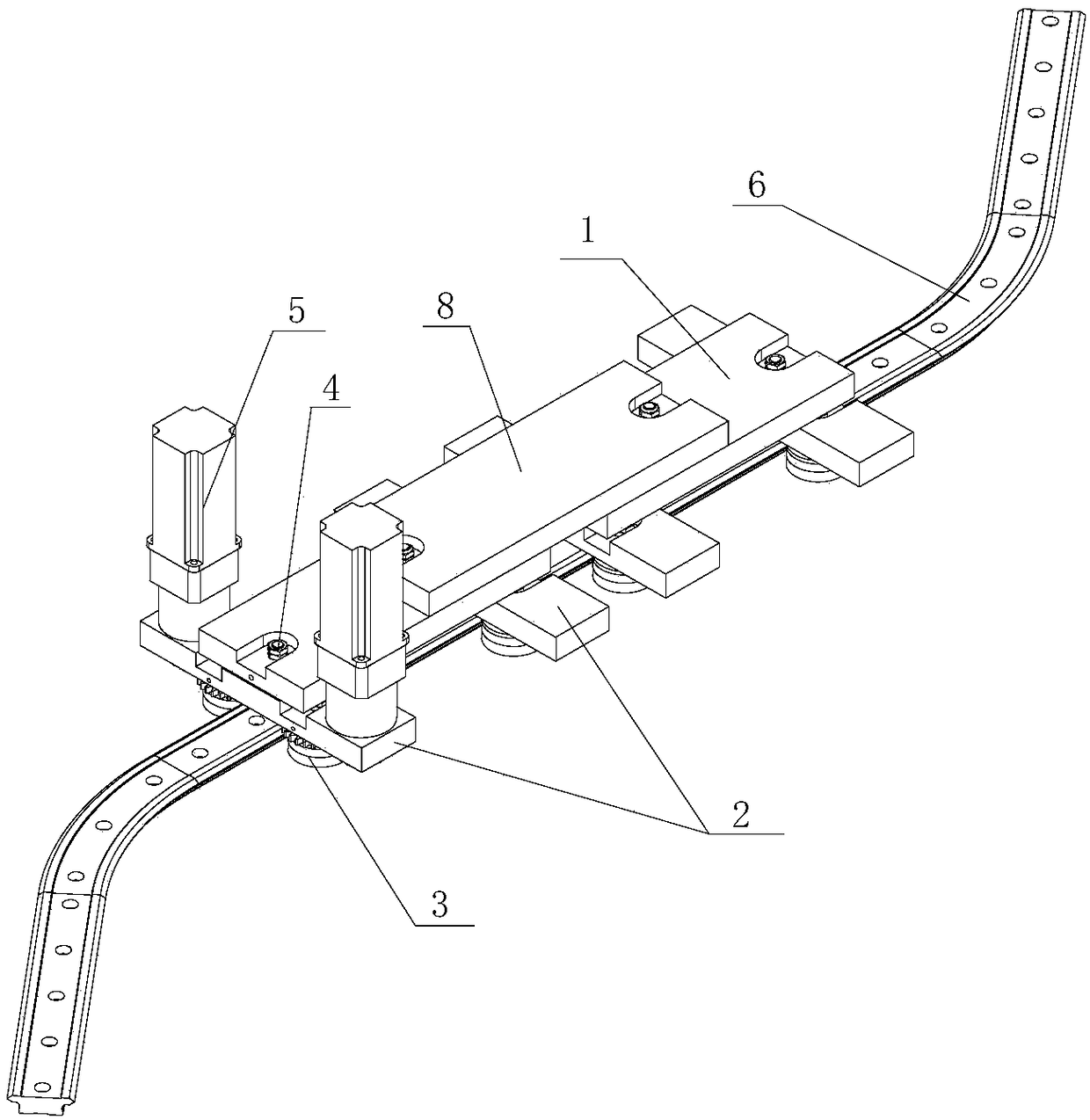

[0024] combine figure 1 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

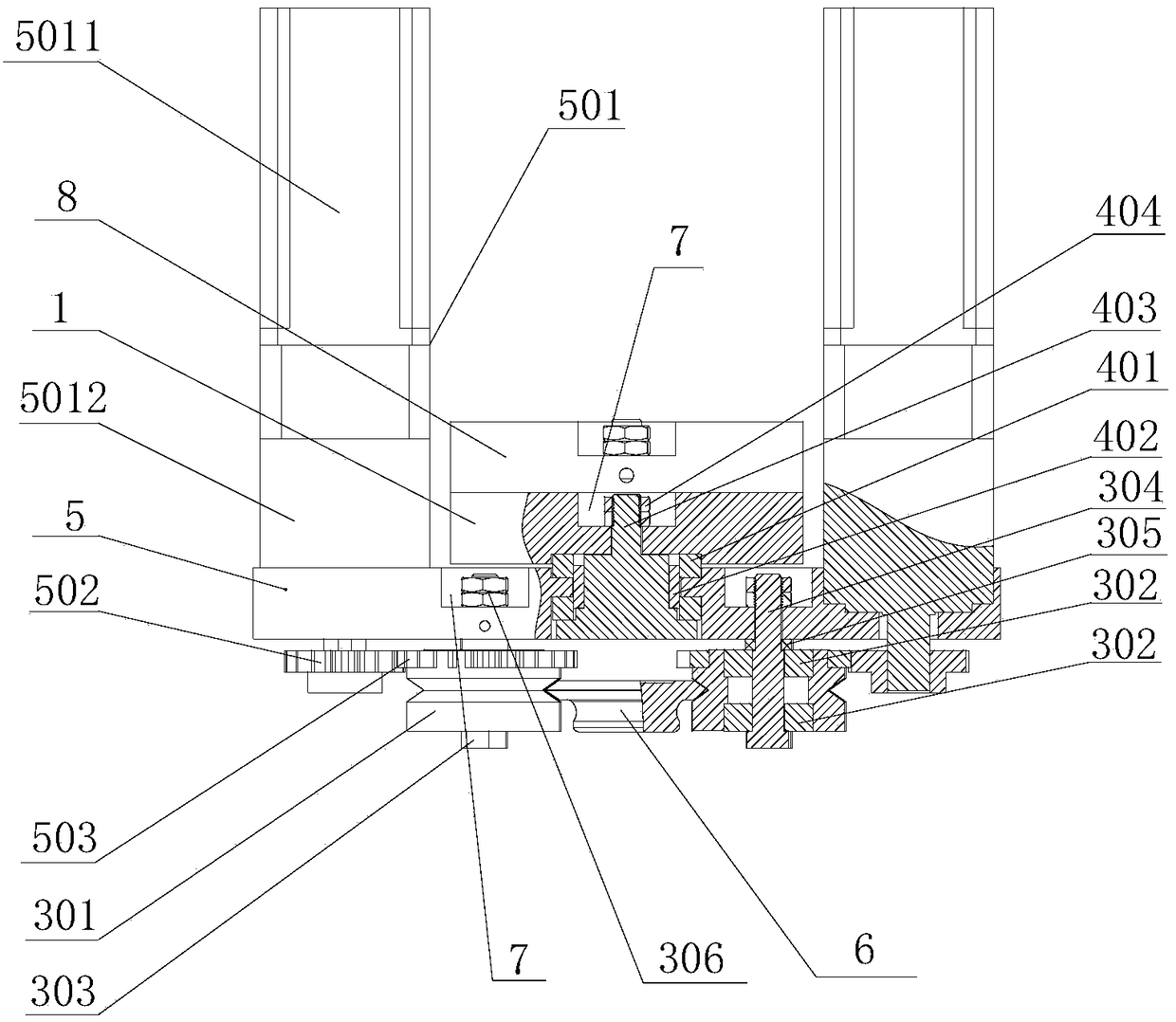

[0025] Such as figure 1 As shown, a self-driven guide trolley suitable for curved guide rails includes an upper loading board 1, two lower loading boards 2, two sets of roller assemblies 3, two sets of steering assemblies 4 and a driving mechanism 5, and each lower loading board 2 is provided with 1 set of roller assemblies 3, the upper loading plate 1 is set above the two lowering plates 2 and is used to horizontally connect the two lowering plates 2, and a set of steering assembly 4 is arranged between the upper loading plate 1 and each lowering plate 2;

[0026] Each set of roller assemblies 3 includes 2 guide rail rollers 301, 2 sets of bearings, centering bolts 303, eccentric bolts 304, 2 spacers 305 and 2 double nuts 306, and the 2 sets of bearings are respectively embedded in 2 guide rails through inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com