Automatic feeding device in automobile radiator production process

A car radiator and production process technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of unsupplyable material output, imperfect automatic feeding device, and affect production efficiency, etc., to achieve improvement The effect of production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

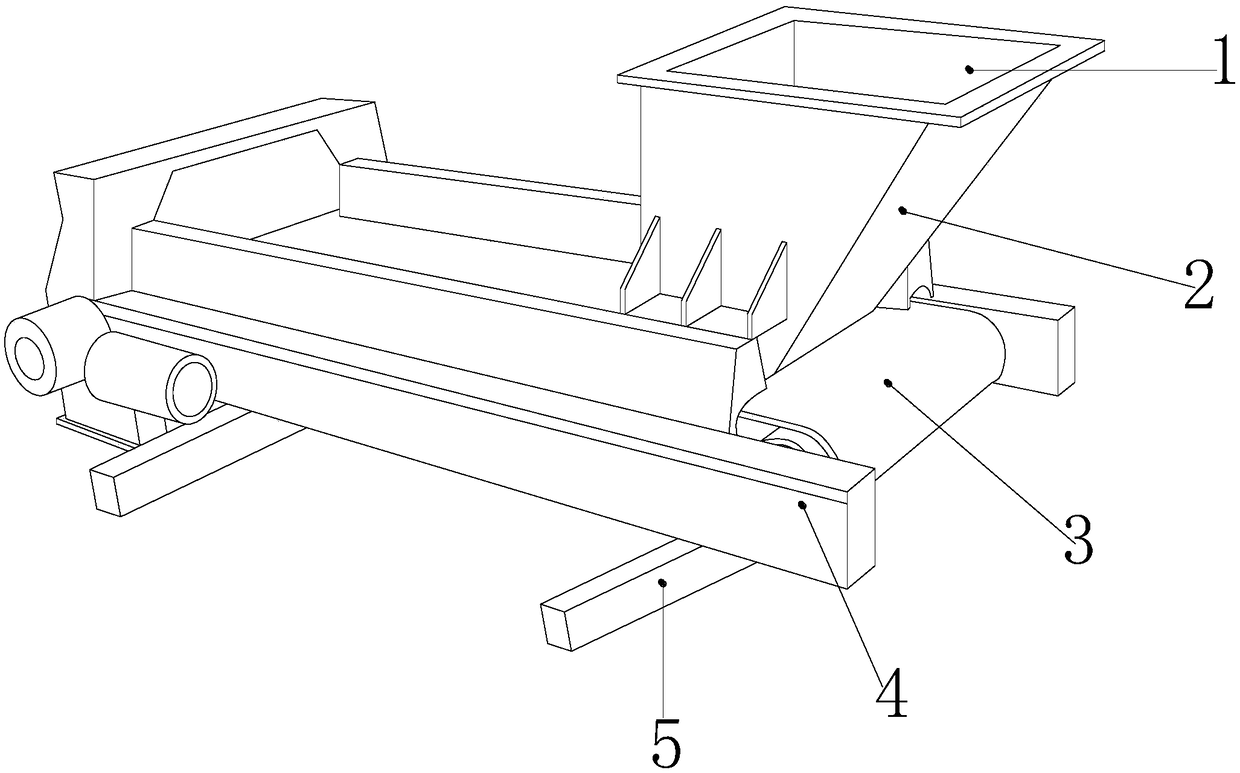

[0029] see Figure 1-Figure 7 , the present invention provides an automatic feeding device in the production process of automobile radiators. Its structure includes a material inlet 1, a sorting device 2, a transmission belt 3, a workbench 4, and a supporting foot 5. The supporting foot 5 is provided with two and They are respectively installed on both sides of the bottom of the workbench 4, the material inlet 1 is installed on the top of the sequence device 2, the sequence device 2 is arranged on one side of the workbench 4, and the transmission belt 3 is installed on the workbench 4 and is mechanically connected with workbench 4;

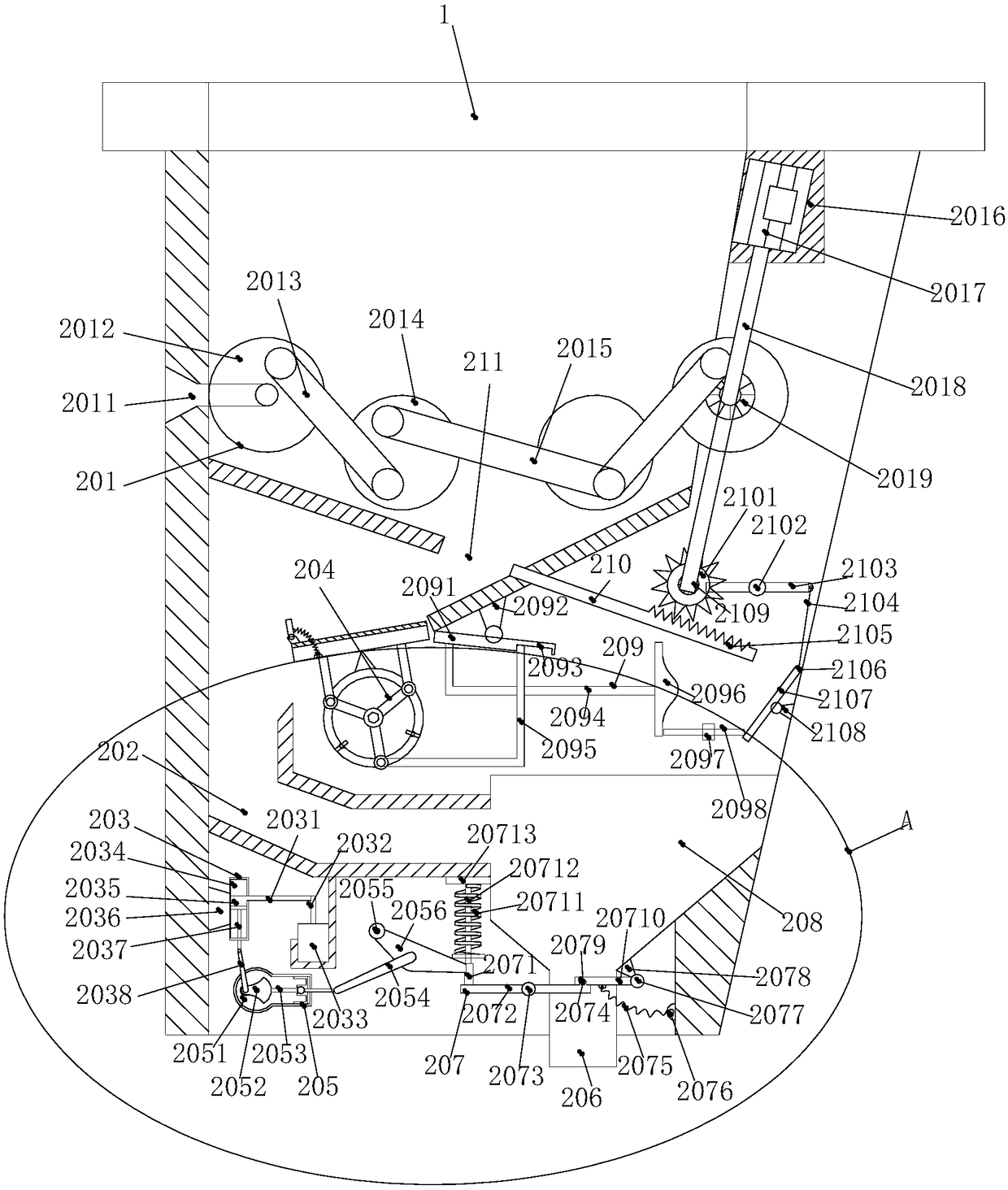

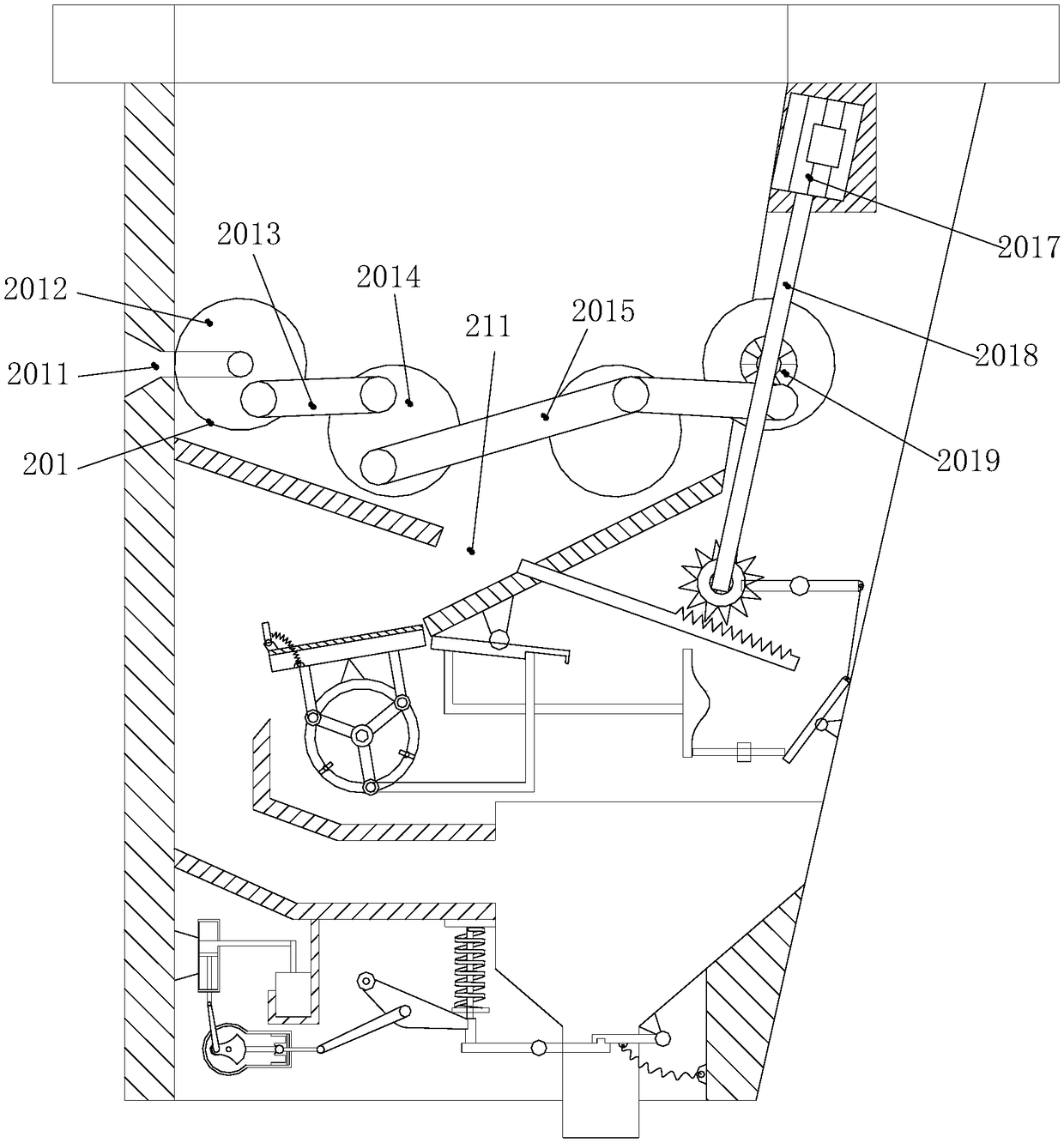

[0030] The described sequence device 2 is composed of a sequence mechanism 201, No. 1 channel 202, a cylinder drive mechanism 203, a transfer transmission device 204, an auxiliary drive mechanism 205, an outlet 206, a discharge control device 207, a material storage chamber 208, and a mechanical drive. Composition of mechanism 209, opening contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com