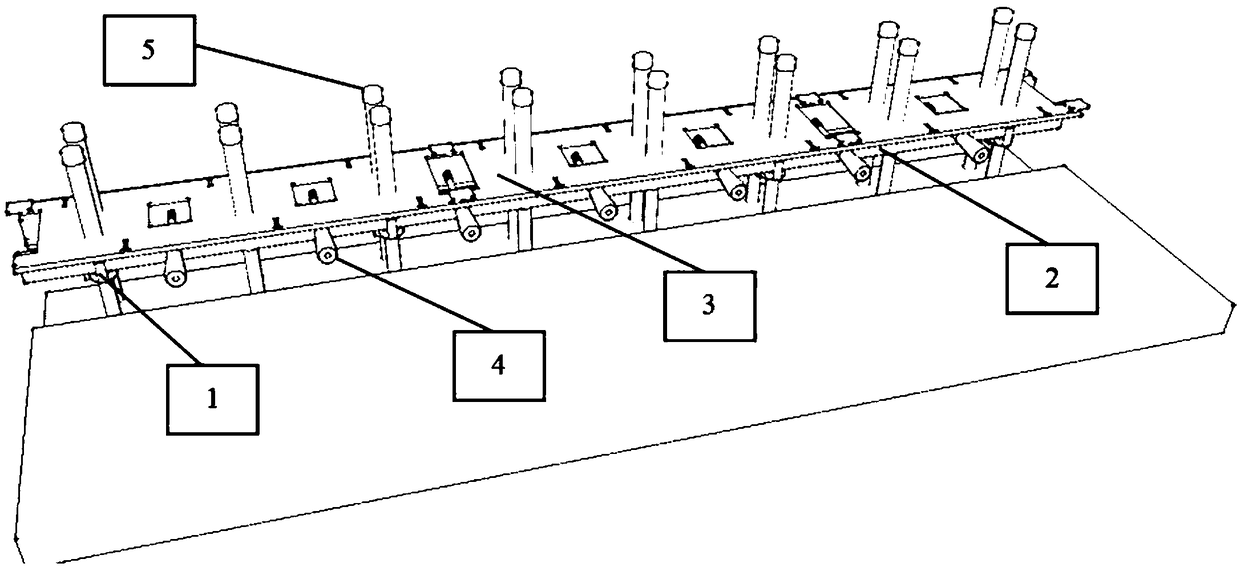

Prefabricated shear wall vertical steel bar positioning device

A technology of vertical reinforcement and prefabricated shear force, applied to structural elements, building components, building reinforcements, etc., can solve the problems of time-consuming and consumable materials, low positioning accuracy, and low versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

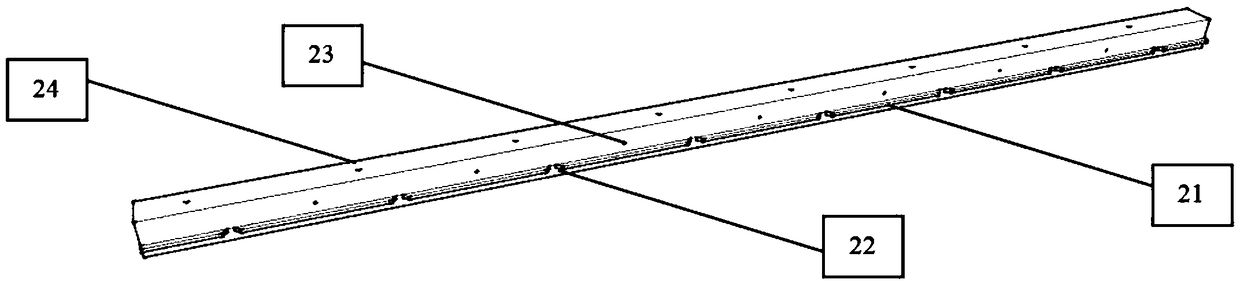

Method used

Image

Examples

Embodiment

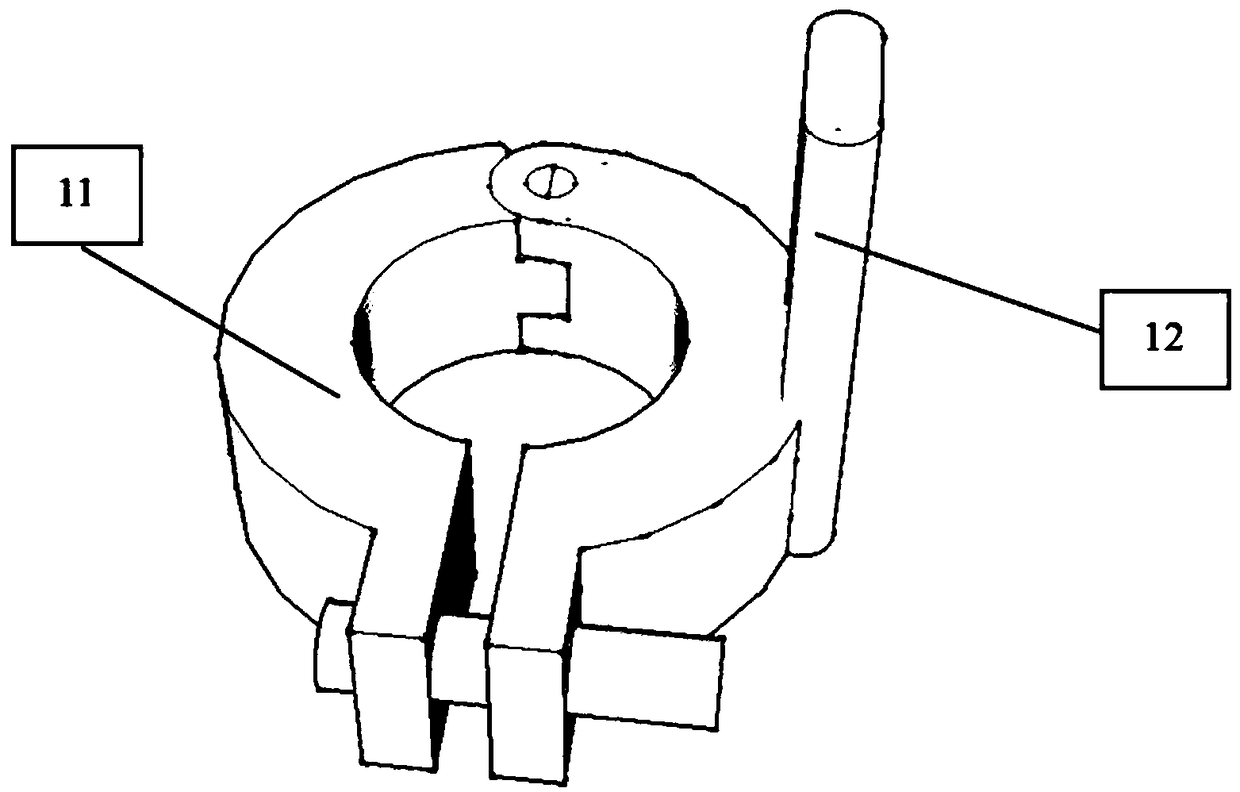

[0028] Transfer layer construction: after the completion of the traditional reinforcement project, the cast-in-place reinforcement mesh in the prefabricated vertical reinforcement pre-embedded area of the prefabricated shear wall is first fixed as a whole, and then the two ends and the middle of the prefabricated wall are pre-embedded according to the vertical reinforcement pre-embedded drawing. Eight vertical steel bars; then, set the horizontal line on the pre-embedded vertical steel bars and install the elevation clip 1, the elevation clip 1 is fixed by a pair of semicircular hoops 11 to hold the steel bars tightly, when the elevation clip 1 is installed It is necessary to ensure that the top surface of the semi-circular hoop 11 is at the same level as the horizontal line, and that the limit block 12 faces the outside of the wall and is parallel to the wall, and install the elevation clip 1 on other pre-embedded steel bars in this way;

[0029] After all the elevation clip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com