Hollow plastic formwork capable of significantly increasing supporting force

A technology of plastic formwork and supporting force, which is applied in the field preparation of formwork/formwork components and building components, construction, etc. It can solve the problems of poor load-bearing capacity, difficult splicing process, and easy deformation, so as to improve the supporting force, The effect of reducing impact and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

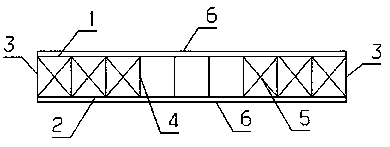

[0016] A hollow plastic formwork that significantly improves the supporting force, including an upper formwork 1, a lower formwork 2 and two side panels 3, the upper formwork 1, lower formwork 2 and two side panels 3 form a hollow cavity, the upper formwork 1 , The thickness of the lower formwork 2 and the side plate 3 is 6-7.5 mm. Several vertical reinforcing ribs 4 are evenly arranged in the hollow cavity, thereby forming several through holes in the hollow cavity, and the thickness of the vertical reinforcing ribs 4 is 2-2.5mm. An X-shaped reinforcing rib 5 is provided in the through hole that accounts for one-third of the total on the left side, and an X-shaped reinforcing rib 5 is provided in the through-hole that accounts for one-third of the total on the right. The thickness of 5 is 1.5~2mm. The upper formwork 1, the lower formwork 2, the side panels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com