Patents

Literature

33results about How to "Speed up the assembly process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

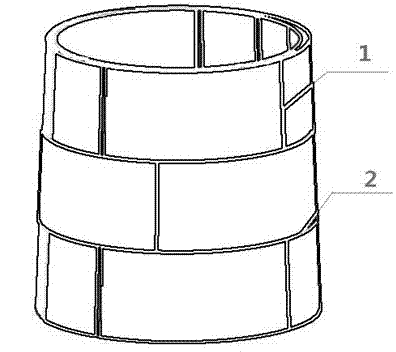

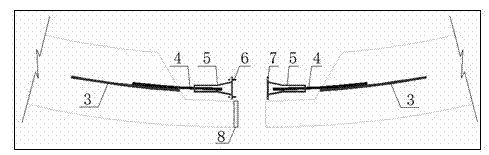

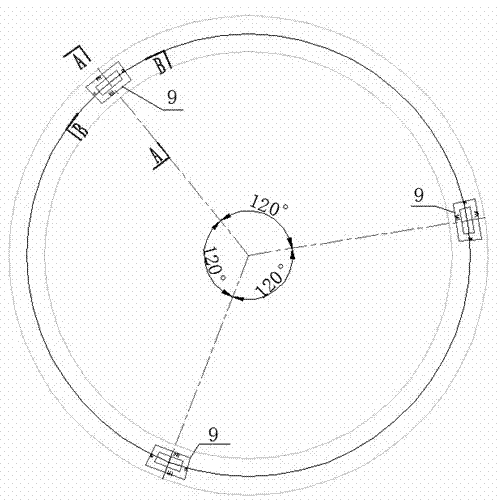

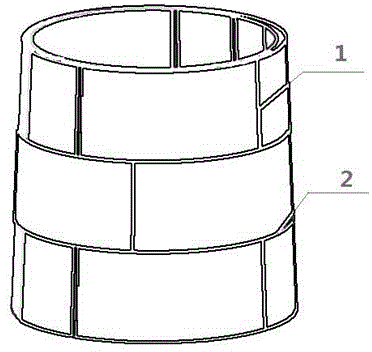

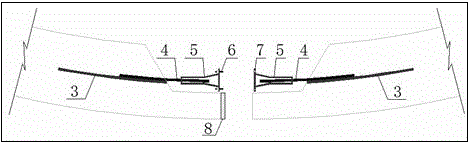

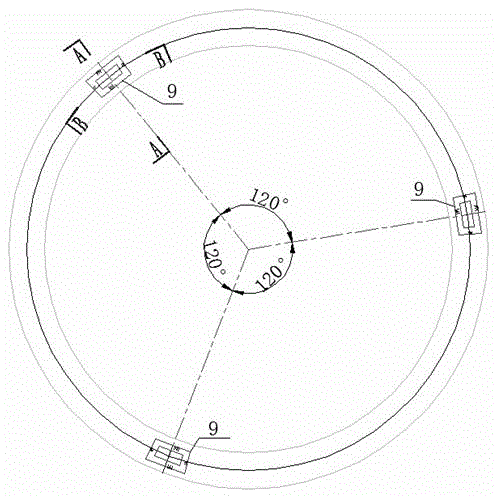

Novel wind power generation precast concrete tower component seaming structure and method

ActiveCN103195668ASpeed up the assembly processReduce design difficultyWind motor componentsEpoxyReinforced concrete

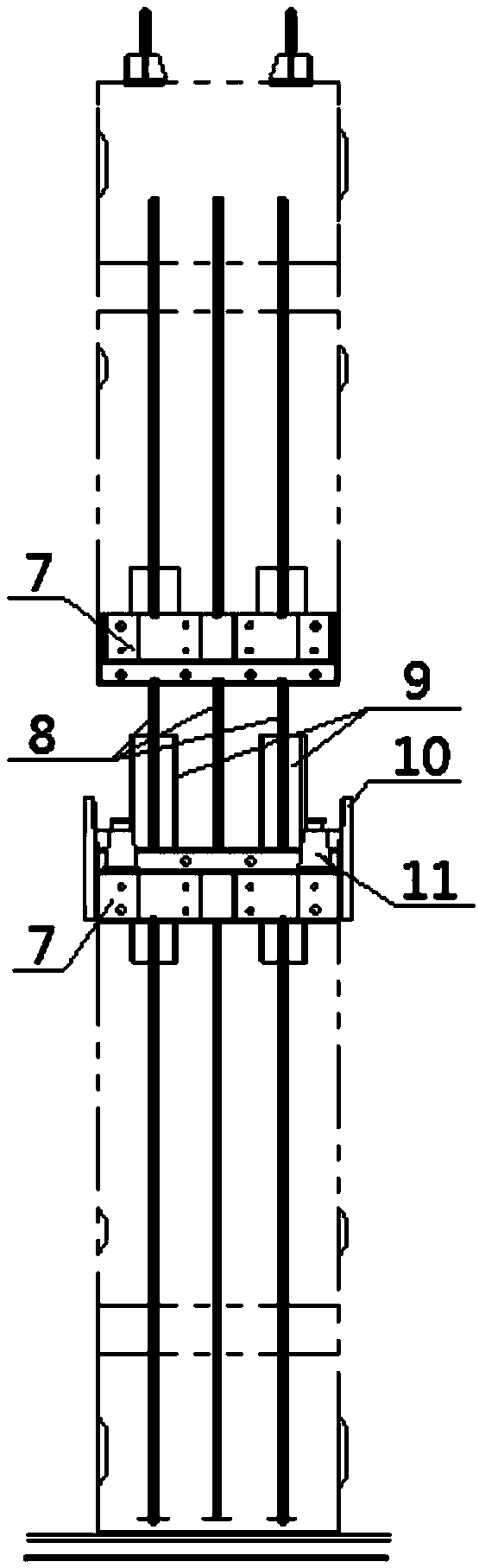

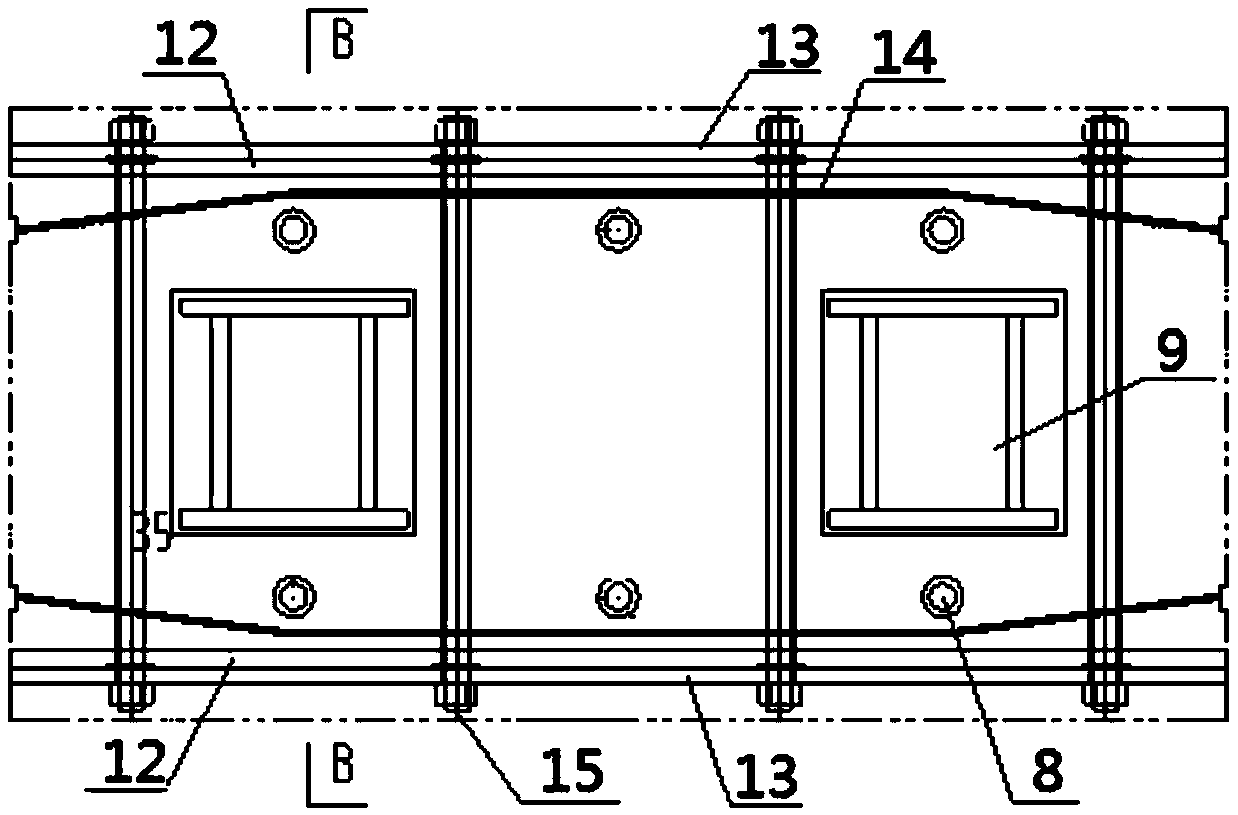

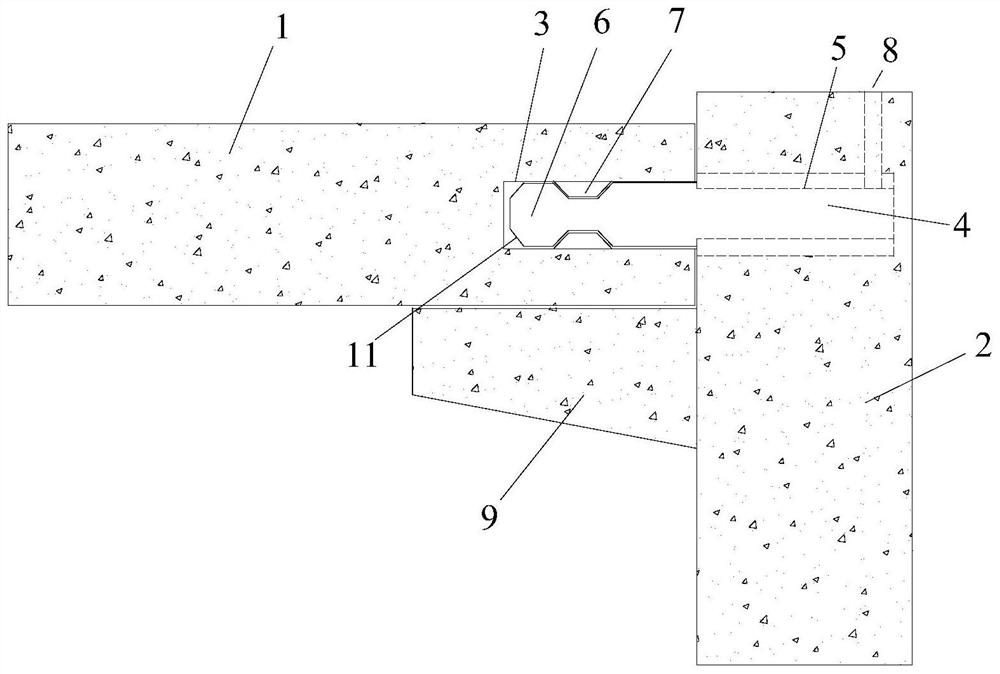

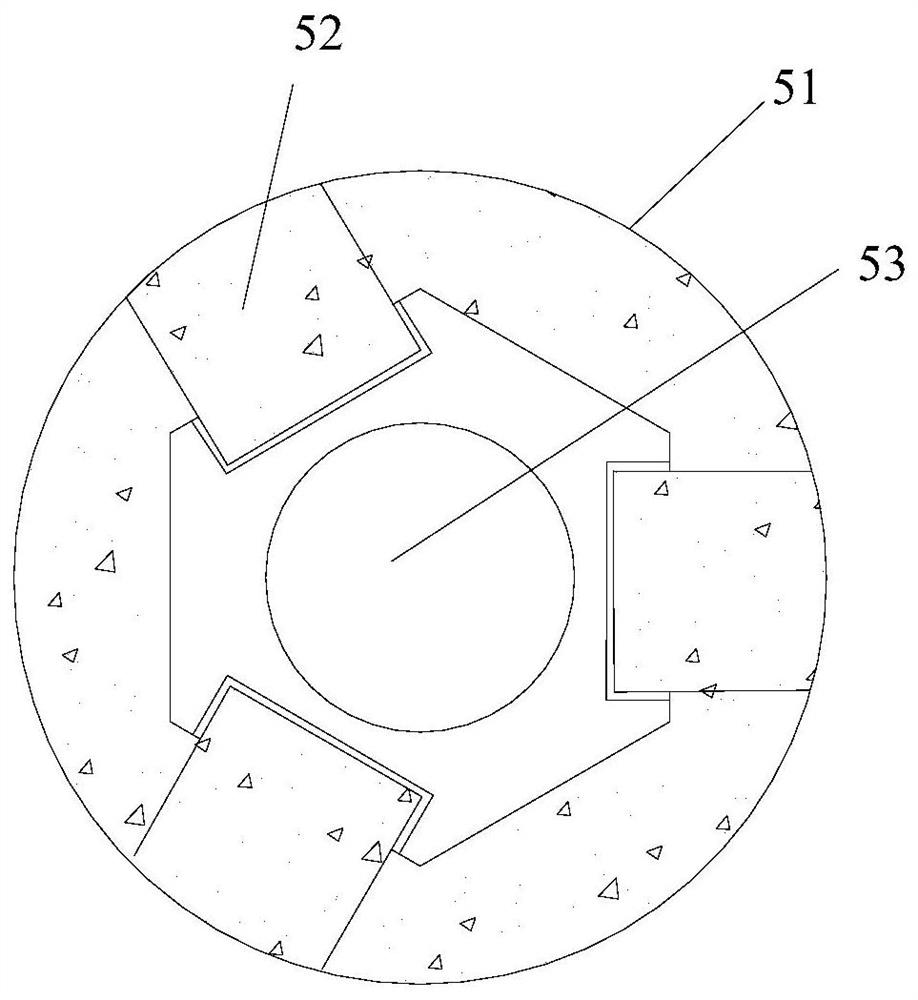

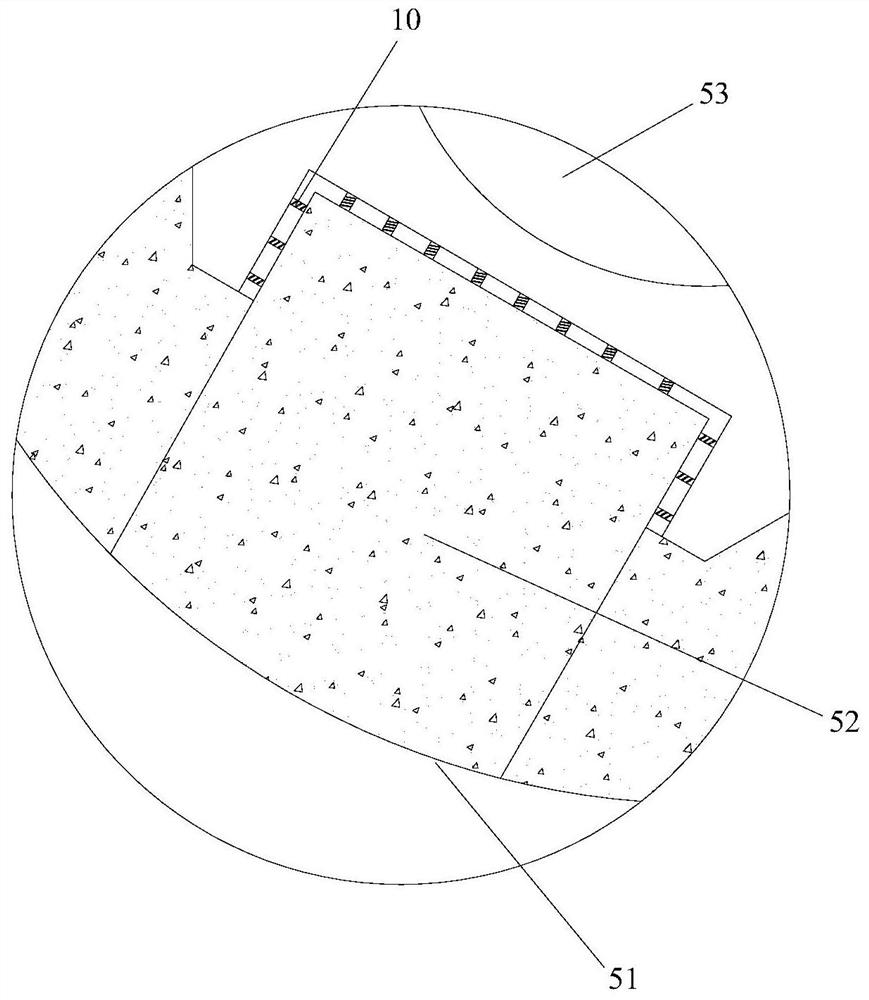

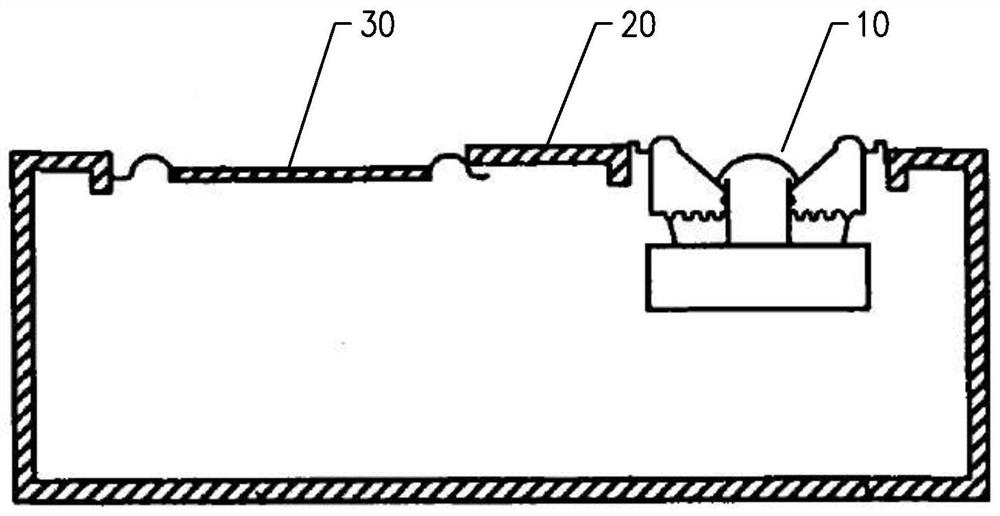

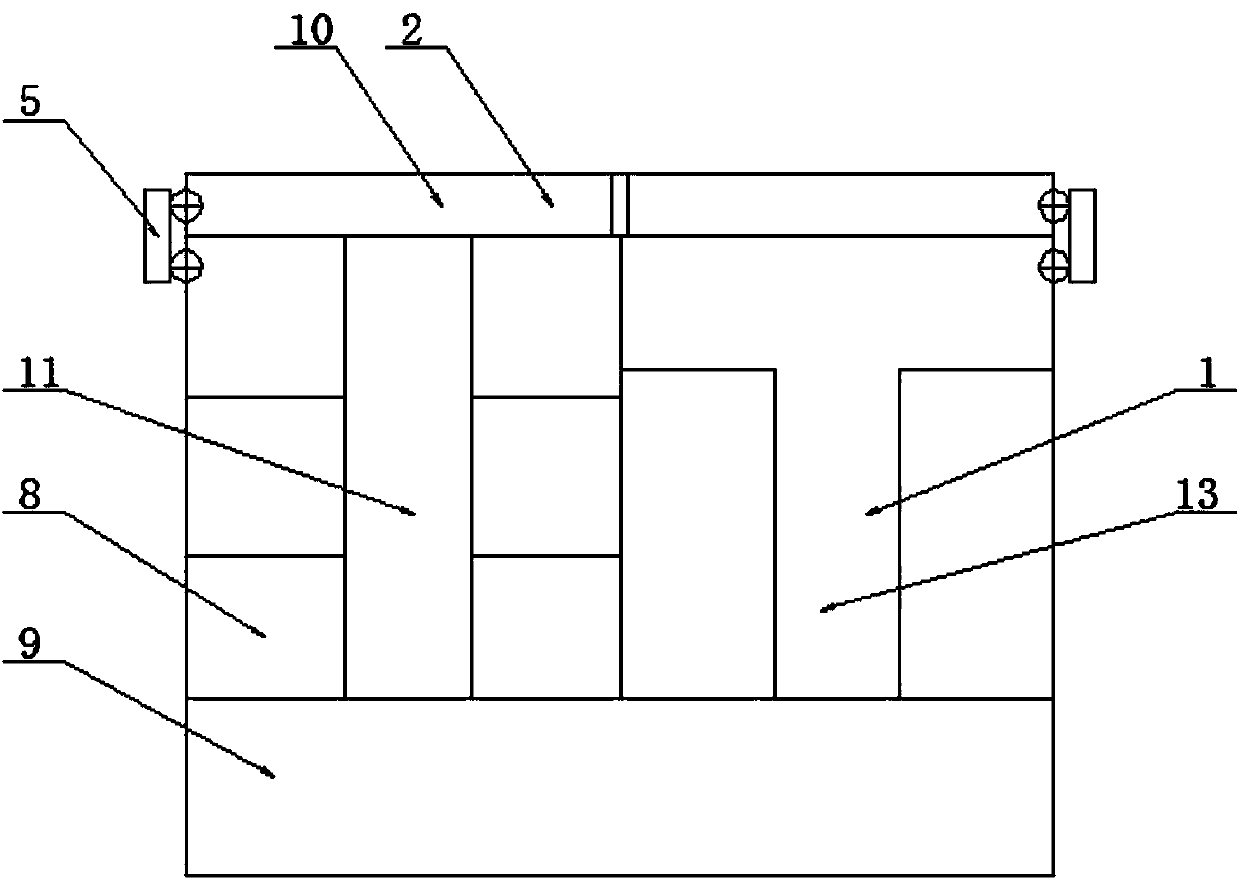

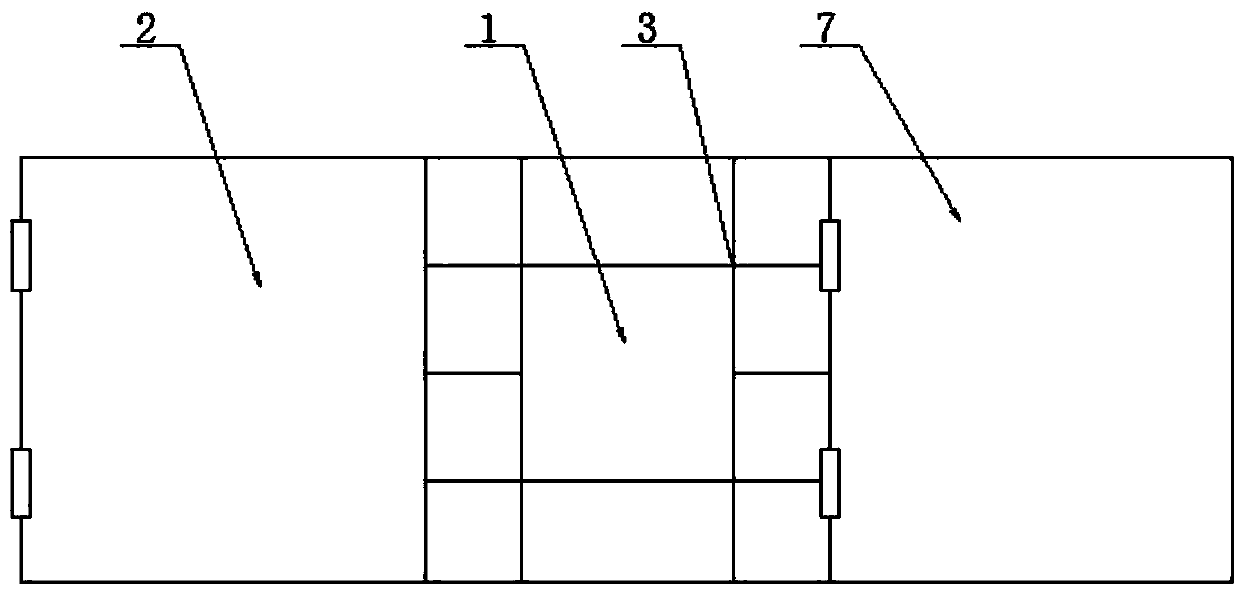

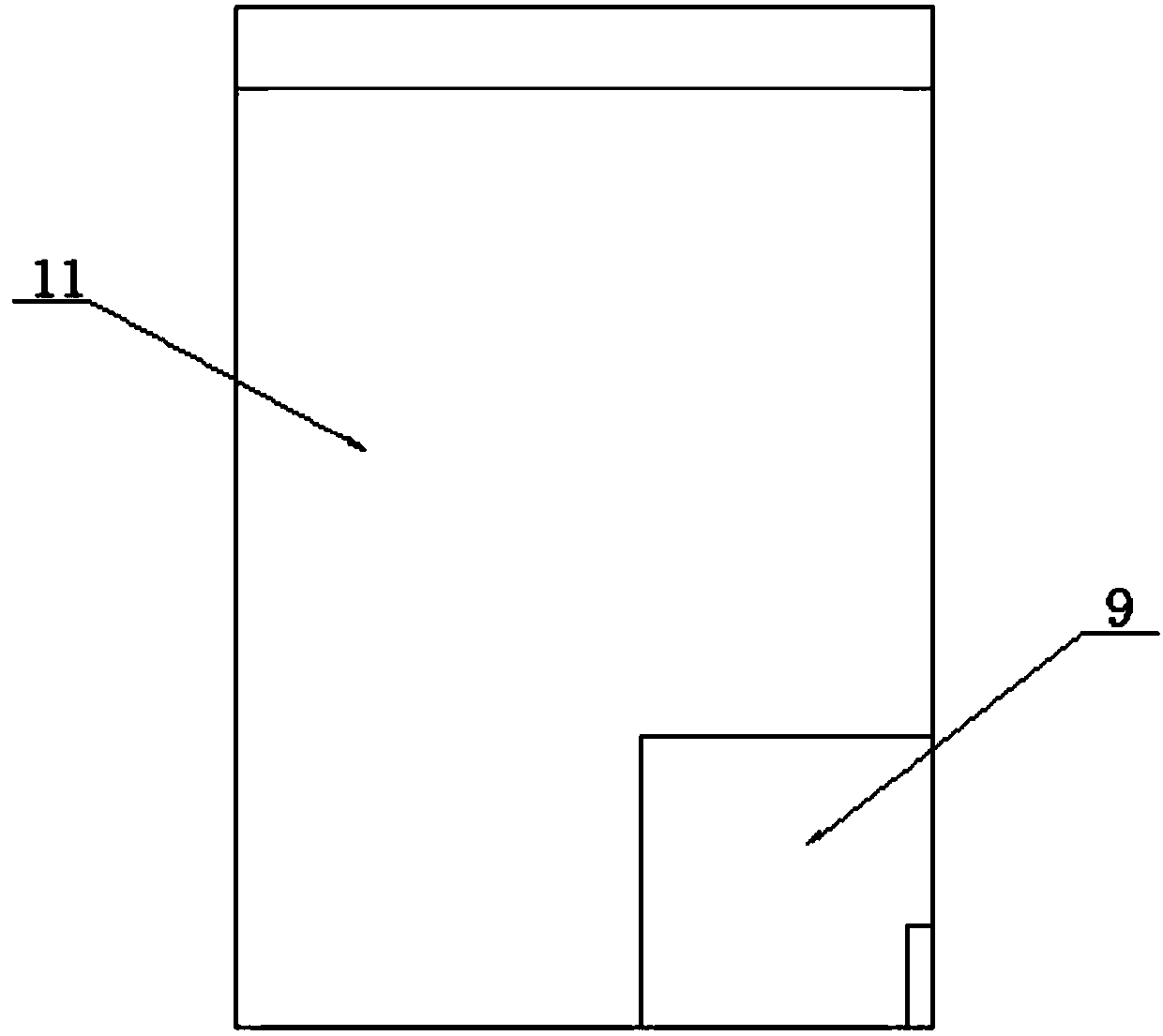

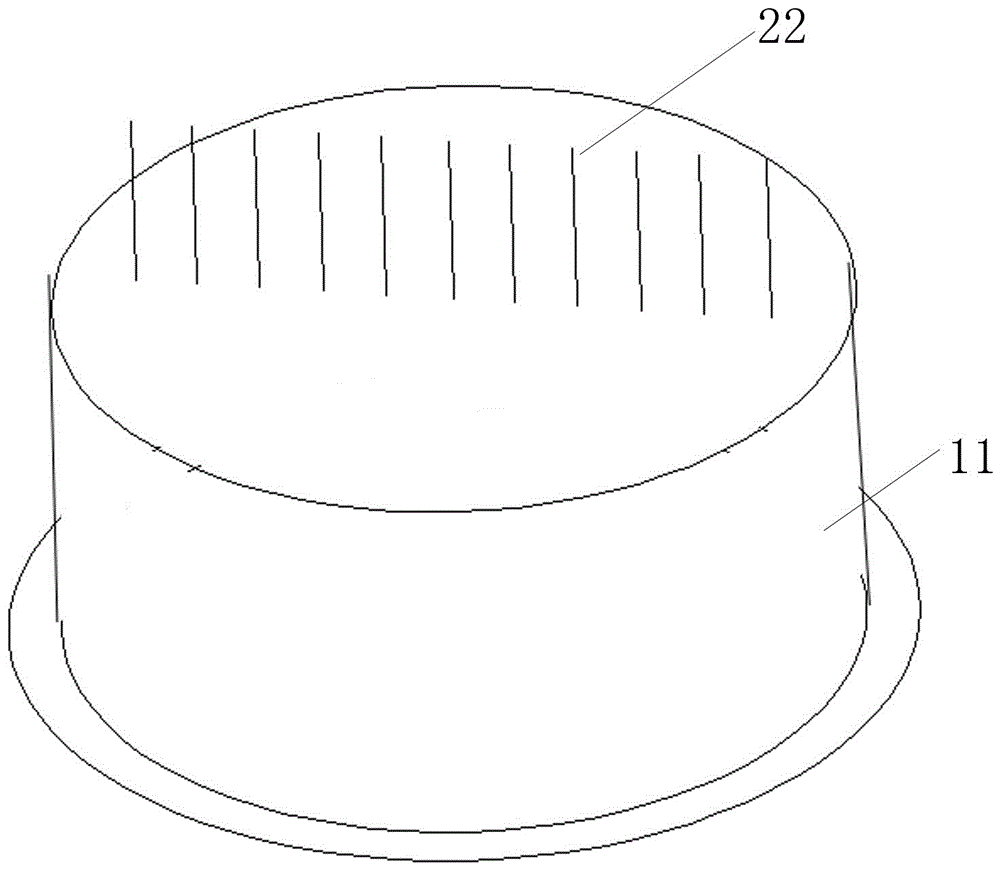

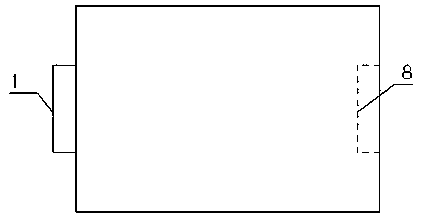

The invention relates to a novel wind power generation precast concrete tower component seaming structure and method. The structure is characterized by at least comprising a longitudinal seam (1), a transverse seam (2), anchoring steel plates (3), high-strength bolts (4), sleeves (5), fixing bolts (6), fixing nuts (7) and waterproof glue (8), the longitudinal seam (1) and the transverse seam (2) are arranged between wind power generation precast reinforced concrete tower components, the precast reinforced concrete tower components are horizontally provided with the anchoring steel plates (3) extending towards the longitudinal seam (1) respectively, the anchoring steel plates (3) are integrally connected with one end of each high-strength bolt (4), the other end of each high-strength bolt (4) is connected with the corresponding sleeve (5) in a threaded manner, the sleeves (5) on two sides are fixedly connected with the fixing nuts (7) through the fixing bolts (6), the upper and lower precast reinforced concrete tower components are respectively provided with a positioning key groove (9) and a positioning key (10) extending towards the transverse seam (2), and each positioning key groove (9) is bonded with the corresponding positioning key (10) through epoxy resin (11). By the aid of the structure, assembly of the precast components can be accelerated, time is saved, the construction method is simple, and construction is facilitated.

Owner:POWERCHINA XIBEI ENG

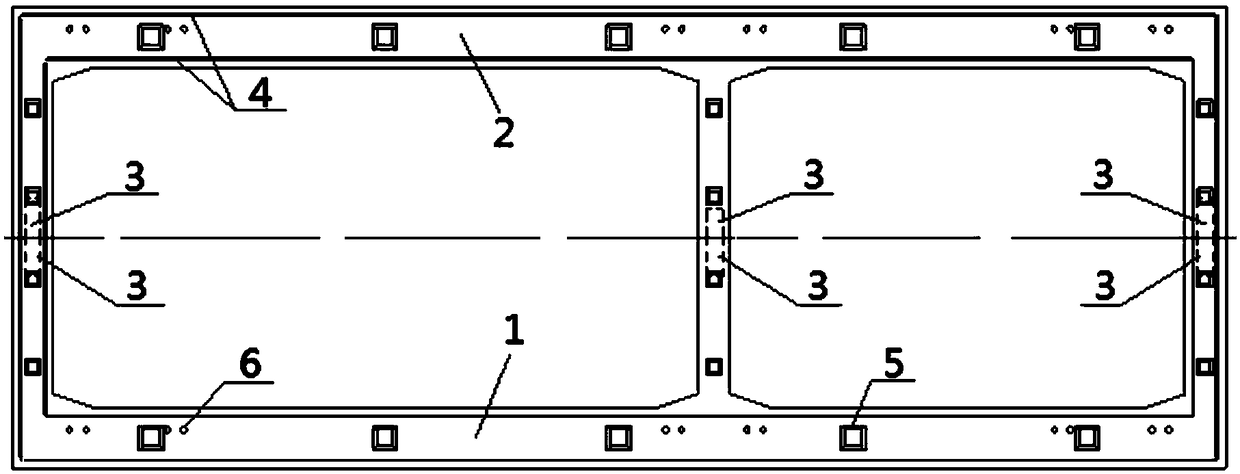

Construction method of fabricated under-crossing tunnel

InactiveCN109208642AStable supportOrderly supportArtificial islandsUnderwater structuresLine segmentBuilding construction

The invention discloses a construction method of a fabricated under-crossing tunnel, comprising the following steps of: a, constructing a concrete foundation at the bottom of the foundation pit, and setting a steel rail thereon; b, lifting a bottom plate over the steel rail in place, lifting and aligning a top plate over the bottom plate and dropping the bottom plate down, and connecting and assembling the bottom plate and the top plate into a ring to form a single tunnel segment; c, assembling subsequent segments into a ring and then pushing the subsequent segment to attach the previous segment, and performing longitudinal permanent prestress compression on the plurality of segments to form a hole segment; d, repeating steps b and c to form a plurality of hole segments, and setting a settlement joint between the adjacent hole segments; e, grouting the gap between the segment bottom plate and the concrete foundation after the assembly is completed. According to the construction method,the under-crossing tunnel can be ensured to be assembled in order, the engineering quality of the entire under-crossing tunnel is ensured, the assembly progress of the under-crossing tunnel is also accelerated, the construction efficiency is improved, and the engineering cost is largely saved.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

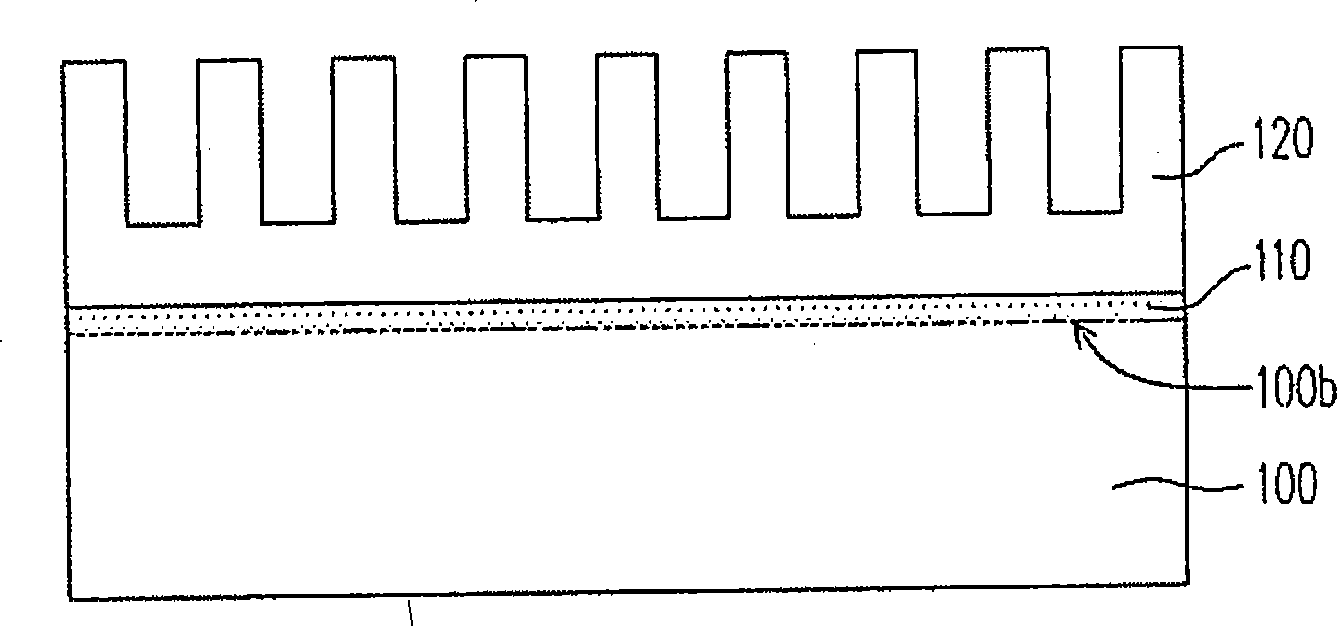

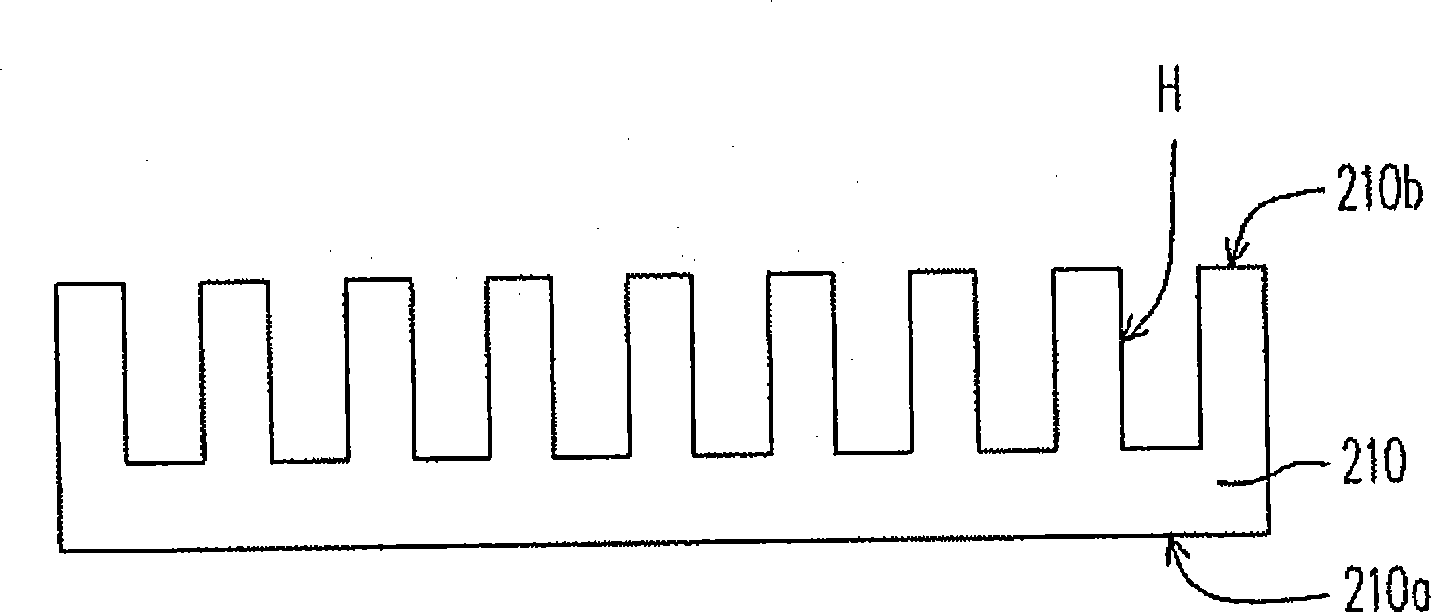

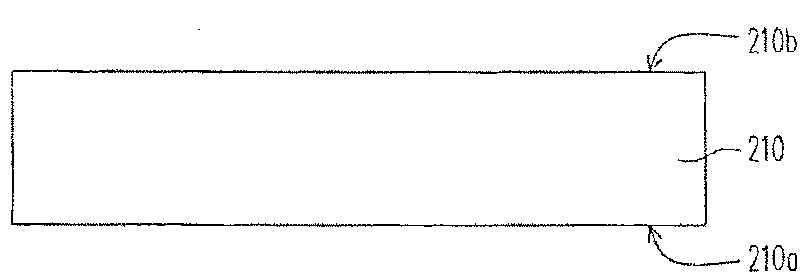

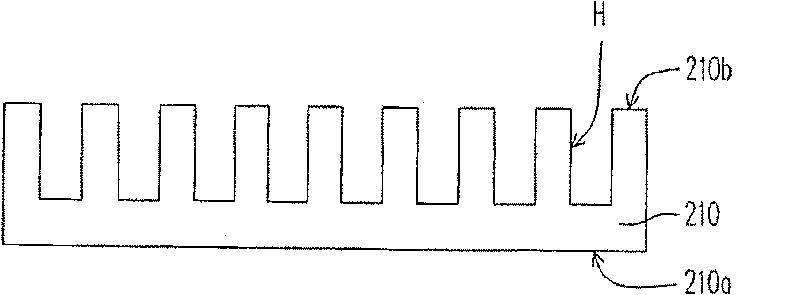

Wafer with radiating structure and its production method

ActiveCN101246862ASolving the assembly process is more troublesomeTime consuming to solveSemiconductor/solid-state device detailsSolid-state devicesMetalActive surface

The invention discloses a wafer having a radiating structure, consisting of a wafer and multiple metal radiating parts. The wafer is provided with an active surface and a back surface opposite to the active surface, wherein the back surface is provided with multiple dead holes. The multiple metal radiating parts are embedded into the head holes, and the metal radiating parts protrude from the back surface of the wafer.

Owner:ADVANCED SEMICON ENG INC

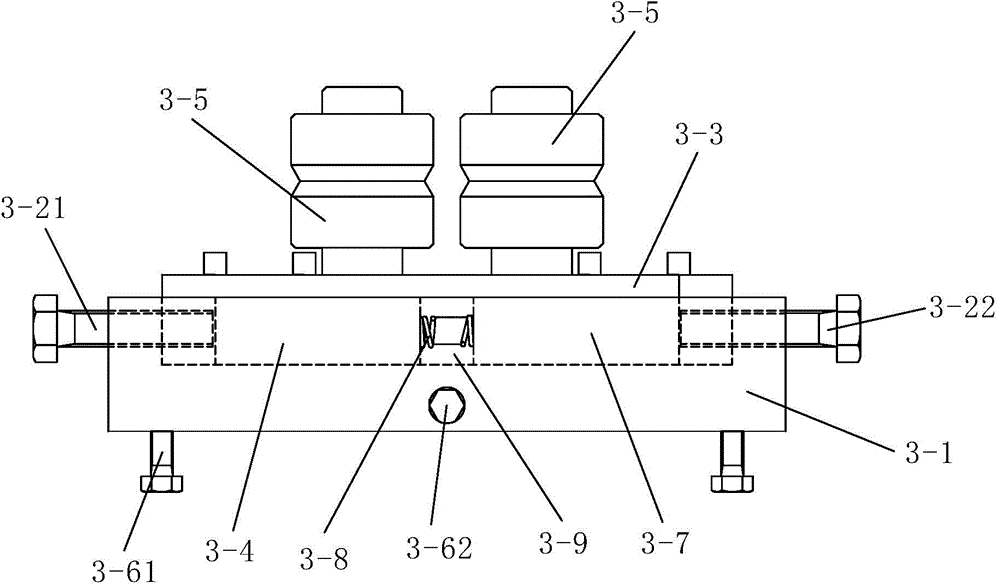

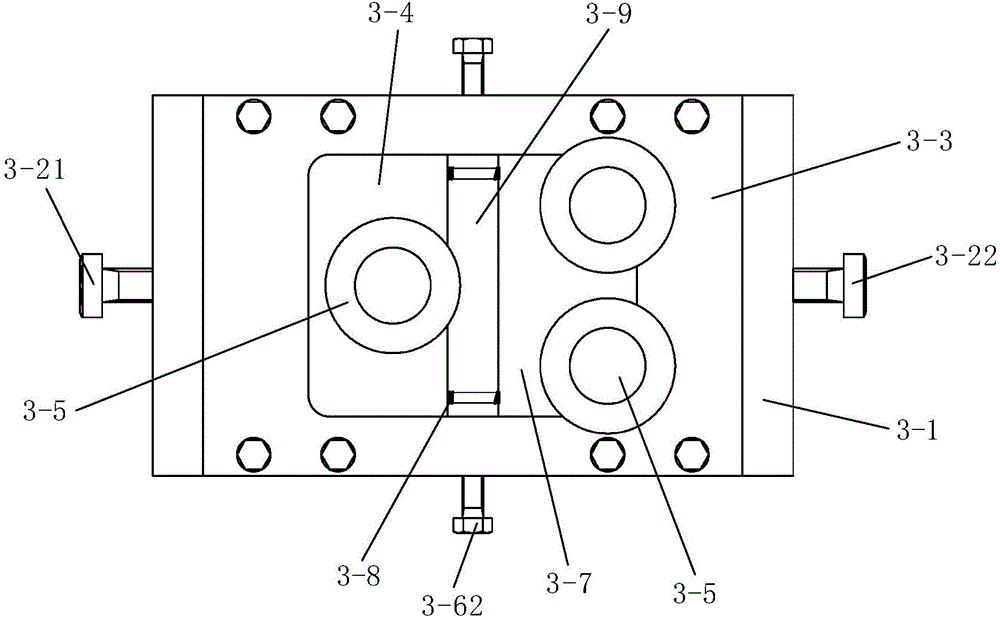

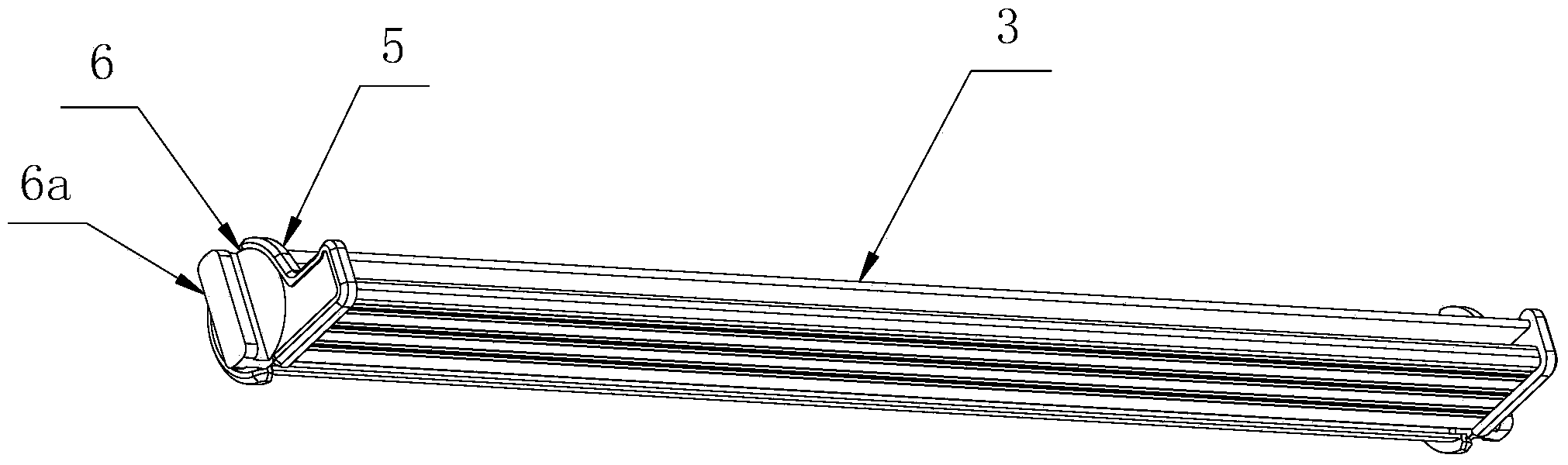

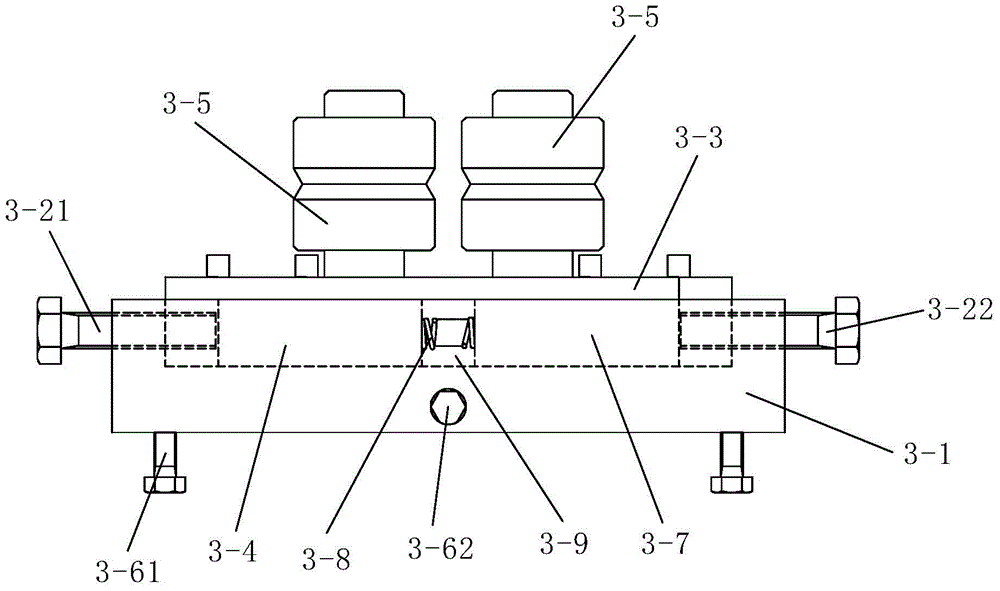

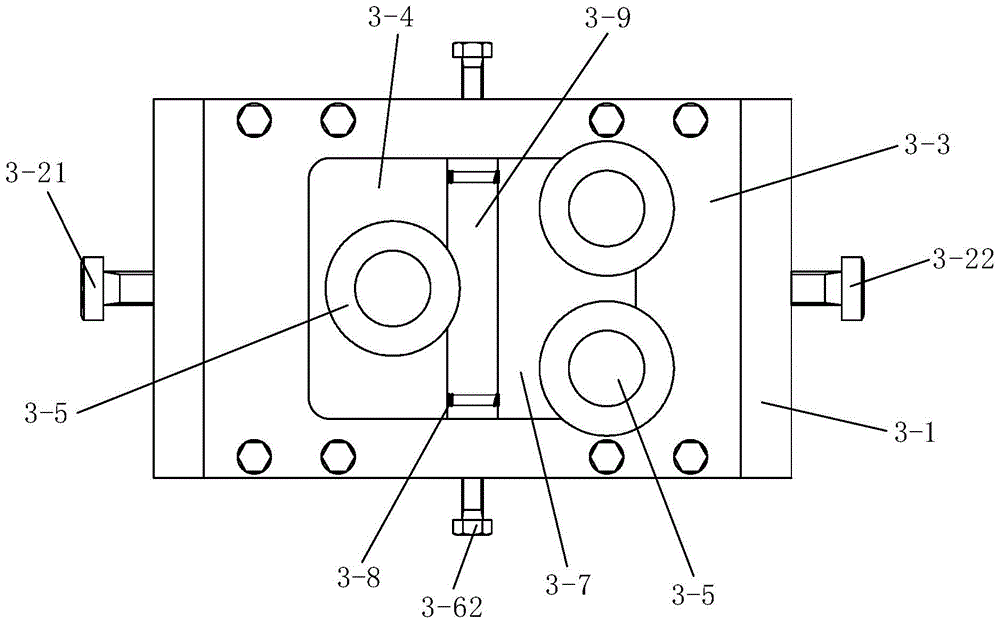

Cu-Nb composite wire straightening device

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Novel wind power generation precast concrete tower component seaming structure and method

ActiveCN103195668BSpeed up the assembly processReduce design difficultyWind energy generationWind motor componentsEpoxyReinforced concrete

The invention relates to a novel wind power generation precast concrete tower component seaming structure and method. The structure is characterized by at least comprising a longitudinal seam (1), a transverse seam (2), anchoring steel plates (3), high-strength bolts (4), sleeves (5), fixing bolts (6), fixing nuts (7) and waterproof glue (8), the longitudinal seam (1) and the transverse seam (2) are arranged between wind power generation precast reinforced concrete tower components, the precast reinforced concrete tower components are horizontally provided with the anchoring steel plates (3) extending towards the longitudinal seam (1) respectively, the anchoring steel plates (3) are integrally connected with one end of each high-strength bolt (4), the other end of each high-strength bolt (4) is connected with the corresponding sleeve (5) in a threaded manner, the sleeves (5) on two sides are fixedly connected with the fixing nuts (7) through the fixing bolts (6), the upper and lower precast reinforced concrete tower components are respectively provided with a positioning key groove (9) and a positioning key (10) extending towards the transverse seam (2), and each positioning key groove (9) is bonded with the corresponding positioning key (10) through epoxy resin (11). By the aid of the structure, assembly of the precast components can be accelerated, time is saved, the construction method is simple, and construction is facilitated.

Owner:POWERCHINA XIBEI ENG

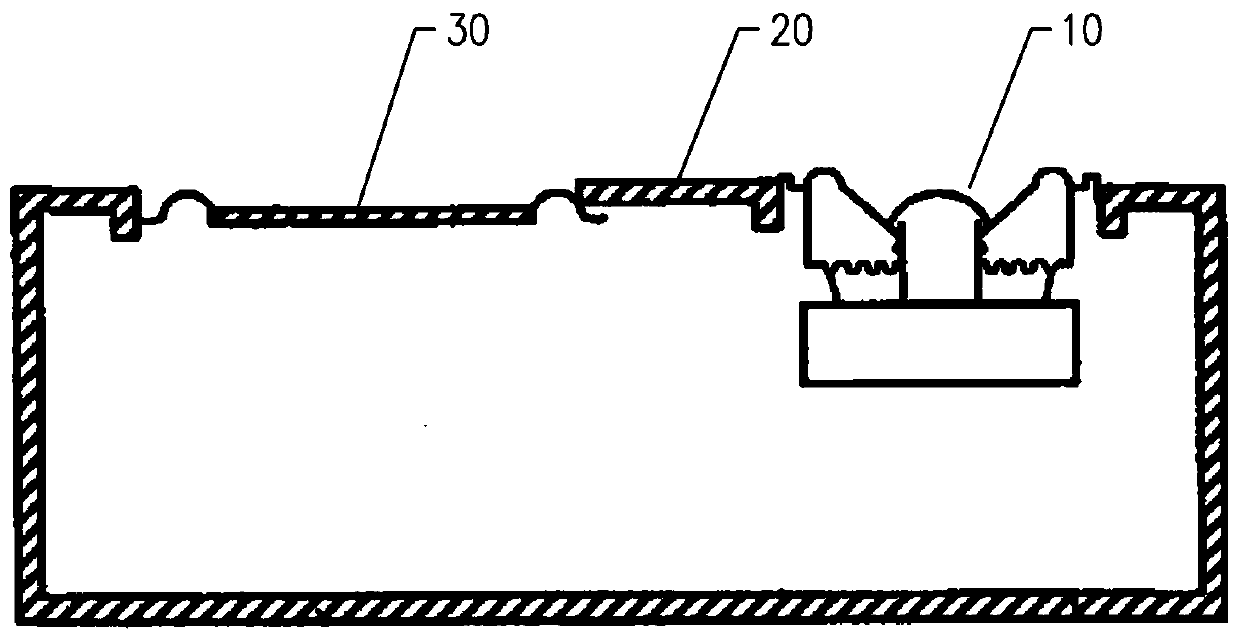

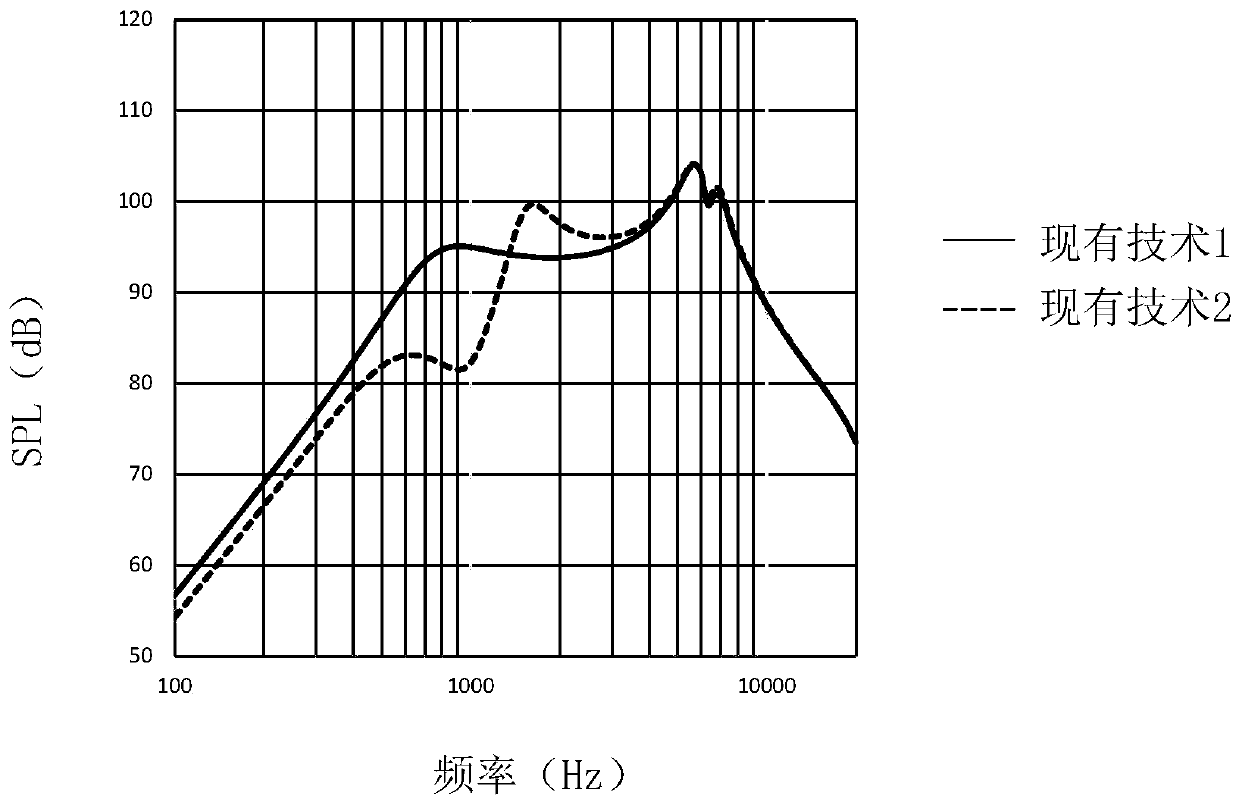

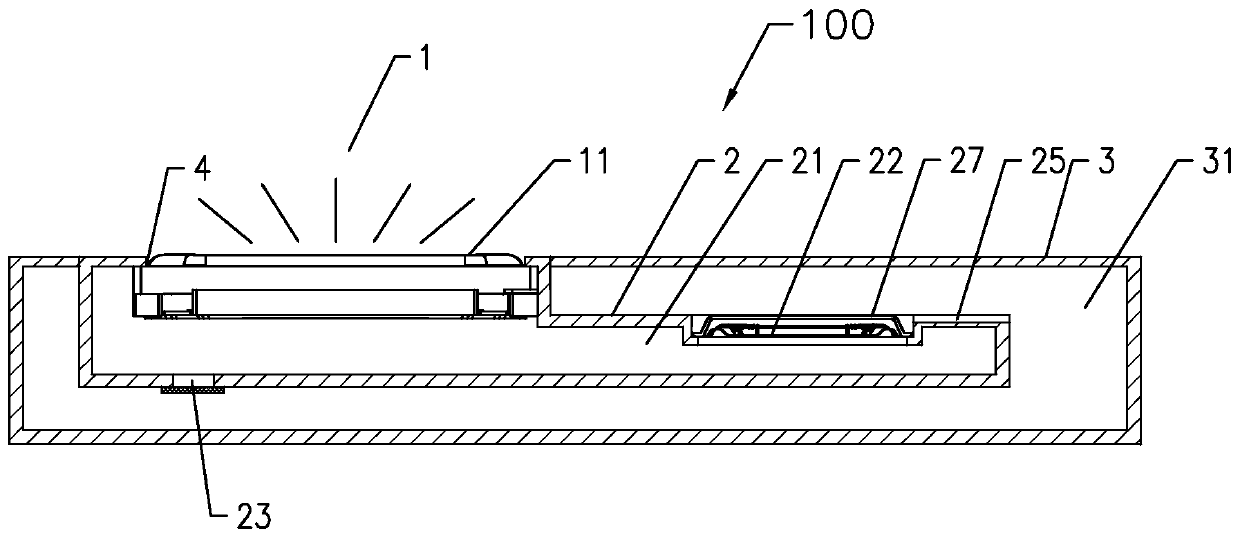

Acoustic device and electronic equipment

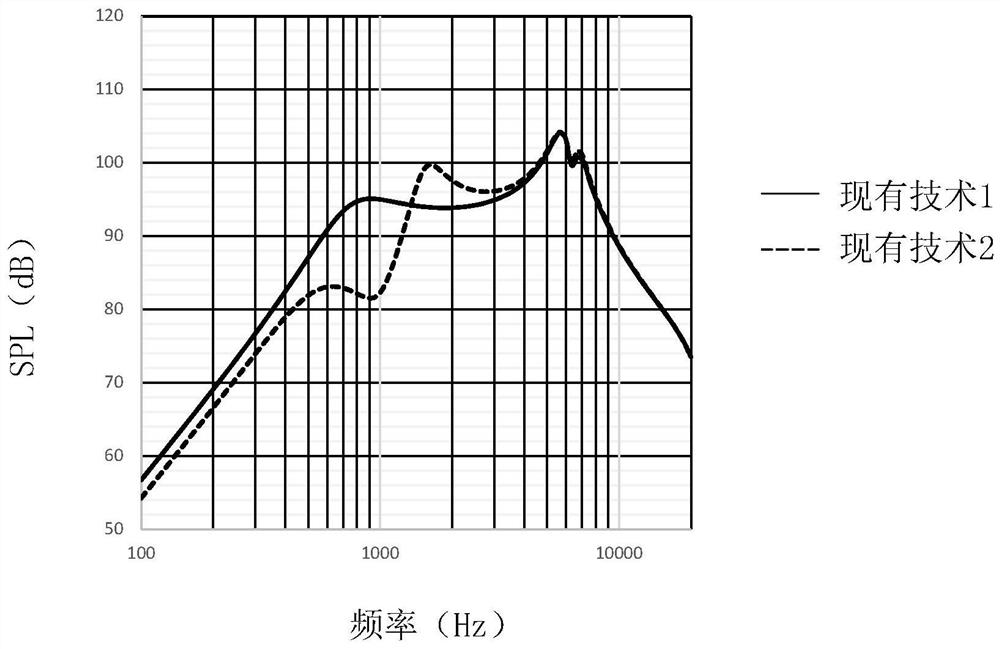

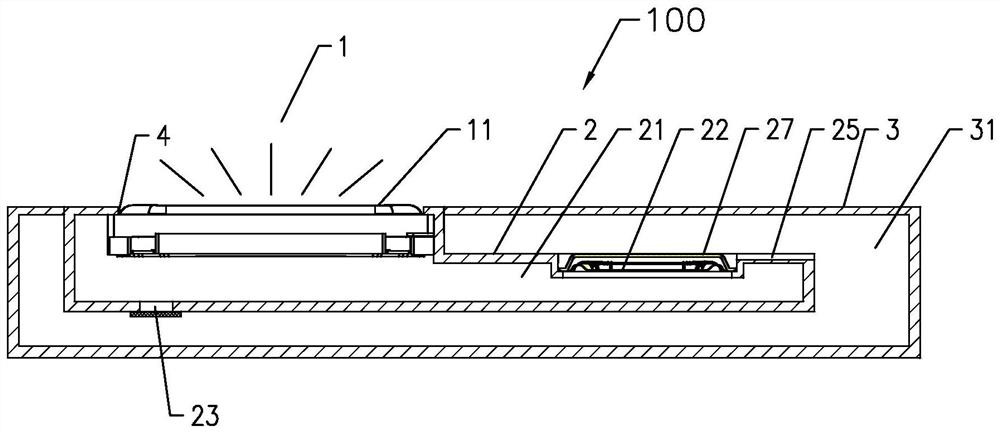

ActiveCN110446139ALower resonance frequencyAdjustable volumeSingle transducer incorporationLoudspeaker screensLow frequency bandSound production

The invention discloses an acoustic device which comprises the components of a sound production unit which radiates sound waves at the front side of a vibrating diaphragm to the outside through a sound outlet; a first closed cavity is formed in the rear side of the vibrating diaphragm; a mounting hole is formed in the cavity wall of the first closed cavity, a flexible deformation part is arrangedon the mounting hole, a second closed cavity is formed in the outer side of the first closed cavity, and sound waves generated by the flexible deformation part during deformation are closed in the second closed cavity through the second closed cavity; a protective cover plate located on the outer side of the flexible deformation part is further arranged on the mounting hole, and an avoiding spaceused for avoiding vibration of the flexible deformation part is formed between the protective cover plate and the flexible deformation part; the protective cover plate is provided with a plurality ofair-permeable micropores, and the area of each air-permeable micropore is smaller than or equal to 0.2 mm < 2 >. According to the acoustic device, the resonant frequency can be effectively reduced, and the low-frequency-band sensitivity of the product is greatly improved on the whole.

Owner:GOERTEK INC

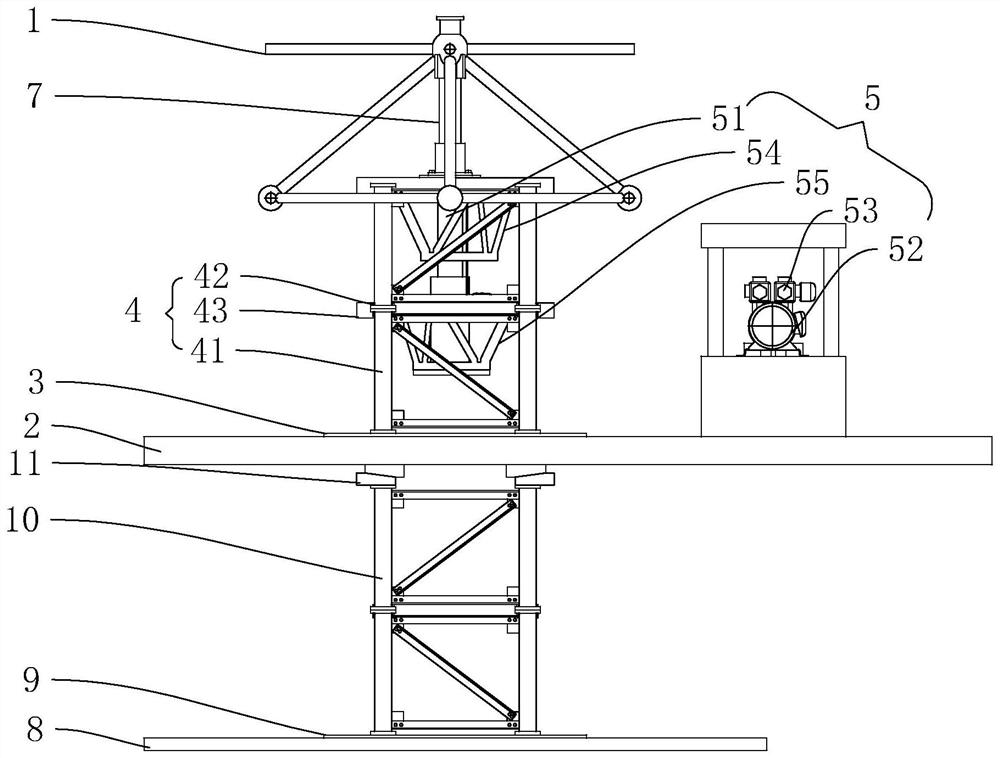

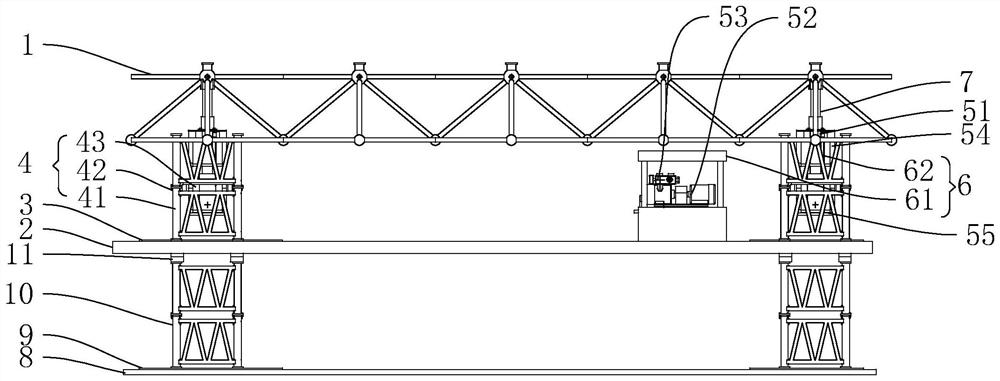

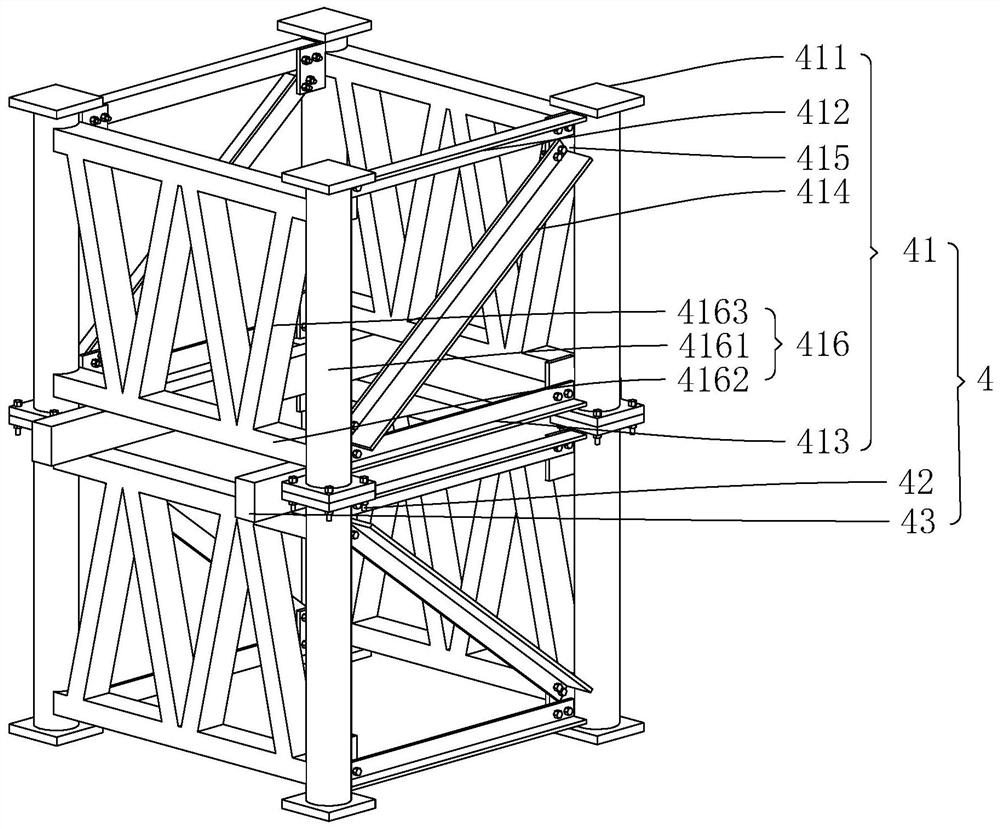

Large-span net rack jacking construction process

InactiveCN111719705AIncreased jacking stability and precisionImprove jacking qualityBuilding material handlingHydraulic ramFloor slab

The invention relates to a large-span net rack jacking construction process. The process comprises the following steps of calculating the jacking number and position; assembling a net rack; mounting ajacking device; reinforcing the floor; jacking the net rack, starting a hydraulic pump to enable a piston rod of a hydraulic oil cylinder to synchronously rise for one stroke, mounting a second standard knot above a first standard knot, enabling a cylinder body of the hydraulic oil cylinder to rise through oil return of the hydraulic pump, and moving a cross beam to the second standard knot to complete one stroke, repeating the net rack jacking step, stopping jacking when the net rack rises to 10-20 cm above the designed elevation; and unloading mounting, enabling the hydraulic oil cylinder to synchronously descend to drive the net rack to fall on a preset mounting base, and completing jacking construction. The process has the effects of shortening the construction period and improving the installation quality and the construction safety.

Owner:中能建西北城市建设有限公司

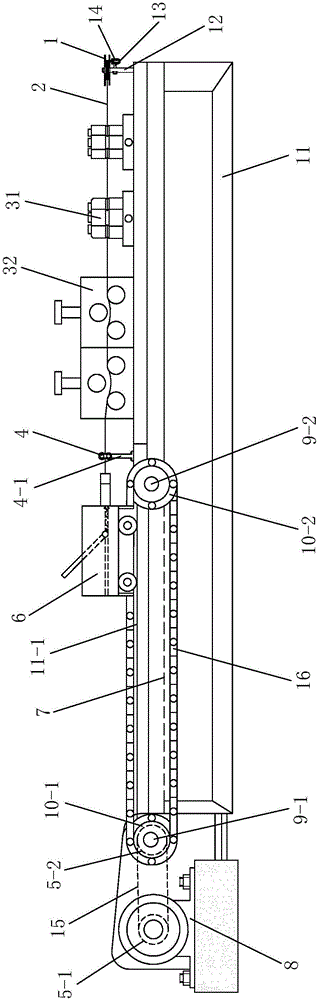

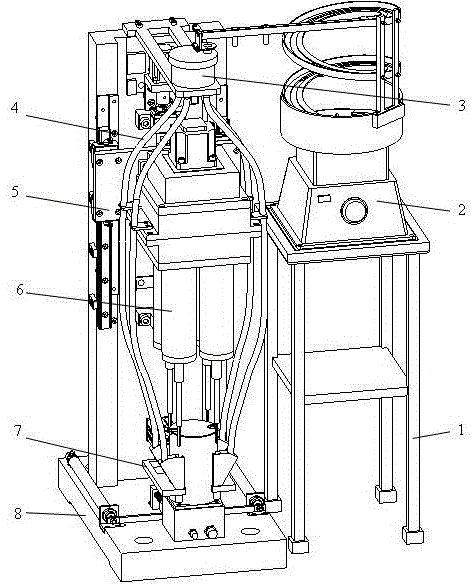

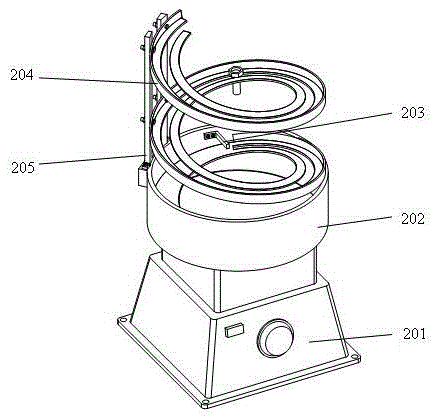

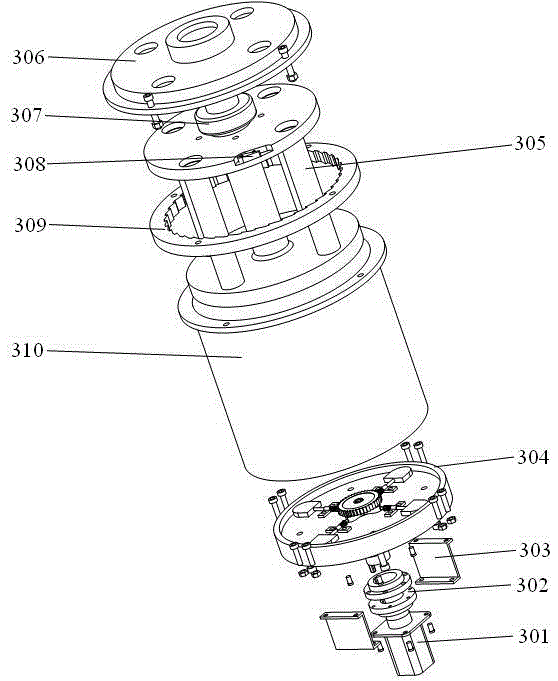

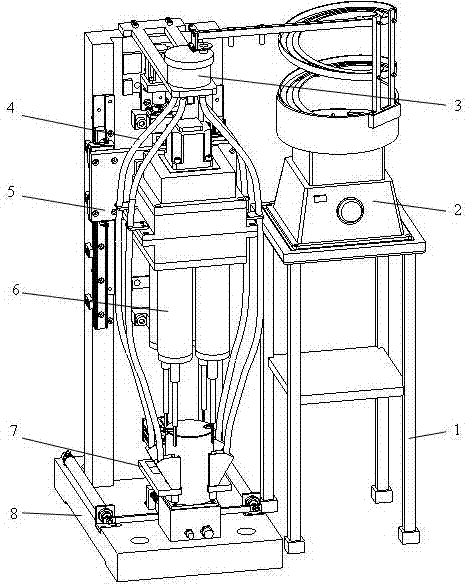

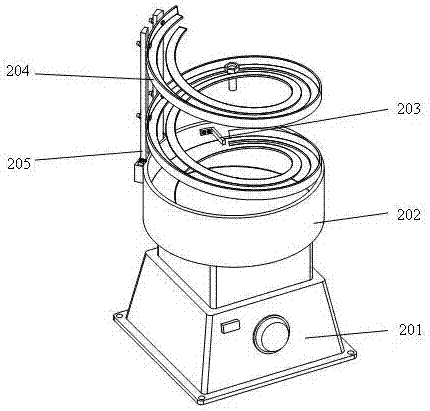

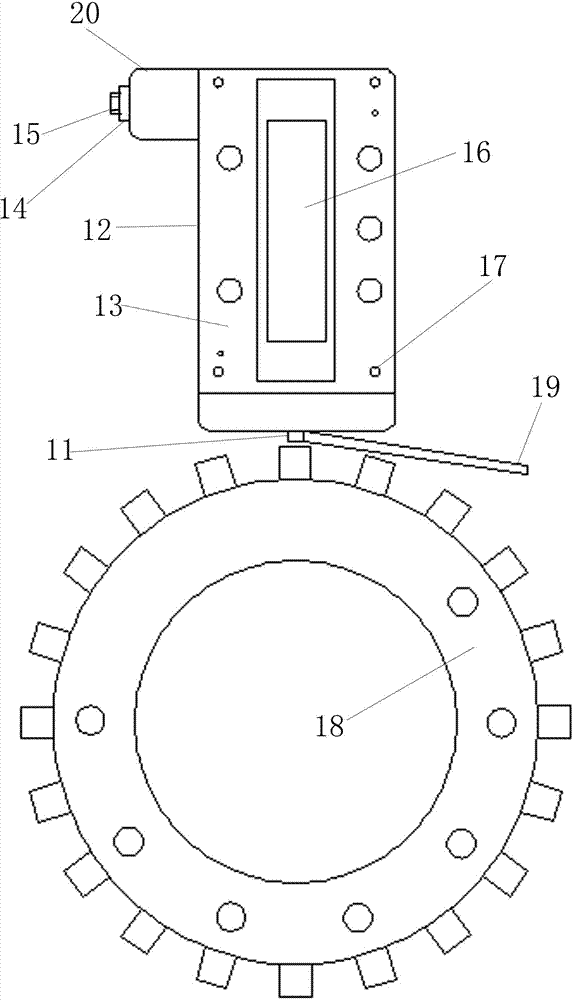

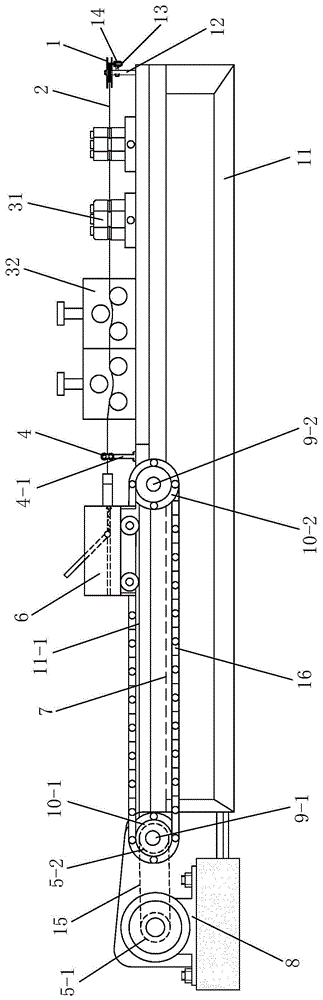

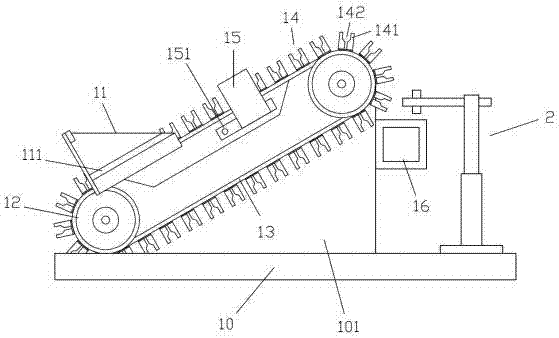

Screw multi-channel automatic feeding and installing integrated machine

ActiveCN105666118ASolve the difficulty of fully automated feedingSolve the material distributionMetal working apparatusEngineeringScrew thread

The invention relates to a screw multi-channel automatic feeding and installing integrated machine, and belongs to the field of mechanical manufacturing. A spiral type vibration feeder is arranged in a positioning groove of a supporting frame and fixedly connected with a screw separating device in a threaded mode through a groove type spiral feeding rail. A shell of the screw separating device is fixedly connected with the supporting frame on a vertical feeding system through threads. A workpiece clamping and positioning system is fixedly connected with a base through threads. A vertical feeding transmission system is fixedly connected with the base. A screwdriver screwing mechanism is fixedly connected with the vertical feeding transmission system through threads. One ends of spiral conveying channels are fixedly connected with the screw separating device, and the other ends of the spiral conveying channels are fixedly connected with a screw feeding and screwdriver guiding part. The screw multi-channel automatic feeding and installing integrated machine has the advantages that the structure is novel, the accurate and efficient screw automatic feeding, distributing and assembling work can be conducted, the assembling progress is greatly accelerated, and the assembling efficiency of the system is improved.

Owner:JILIN UNIV

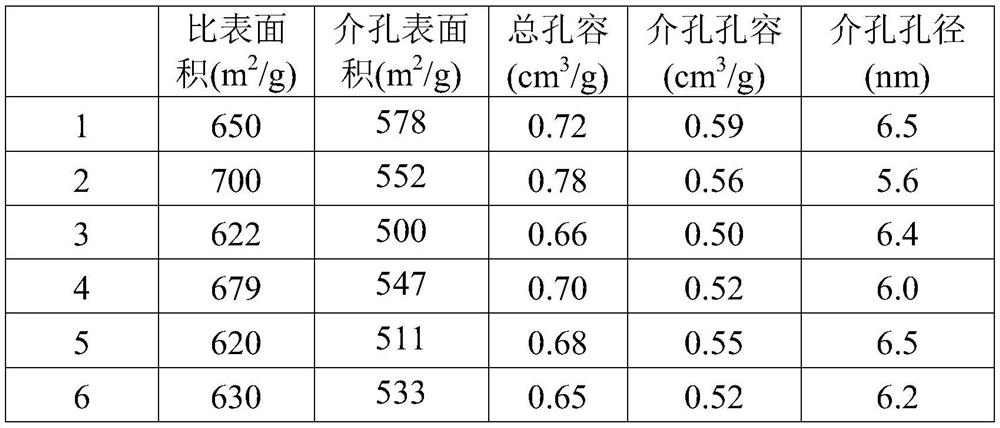

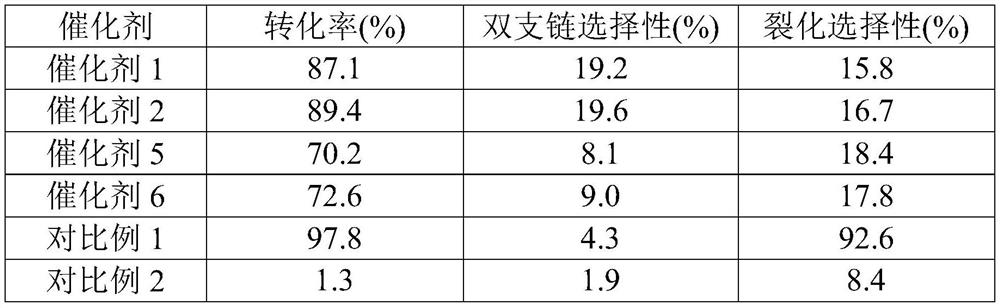

Preparation method of SBA-16/MOR composite molecular sieve, catalyst and application in double branched chain isomerization

ActiveCN112642474ALow costReduce pollutionMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention relates to the field of petroleum processing, discloses a preparation method of a novel SBA-16 / MOR composite molecular sieve material and application in double branched chain isomerization for the first time, and in particular relates to a low-cost green preparation method of an SBA-16 / MOR composite molecular sieve material with suitable acidity and a three-dimensional stepped pore channel structure and a double-branched-chain isomerization catalyst prepared by loading non-noble metal on the SBA-16 / MOR composite molecular sieve material. The catalyst is applied to a catalytic cracking (FCC) gasoline hydroisomerization reaction. According to the catalyst, natural minerals are used as raw materials for green synthesis of an MOR molecular sieve nanocrystalline precursor solution without a template agent, and then an SBA-16 / MOR composite molecular sieve carrier is prepared through in-situ assembly by adopting a prehydrolysis method under low acidity, so that the production cost is greatly reduced, the equipment damage is relieved, and the pollutant emission is reduced. Therefore, the method provided by the invention has good economic and environmental benefits, and provides technical support for upgrading the quality of oil products in China.

Owner:PETROCHINA CO LTD +1

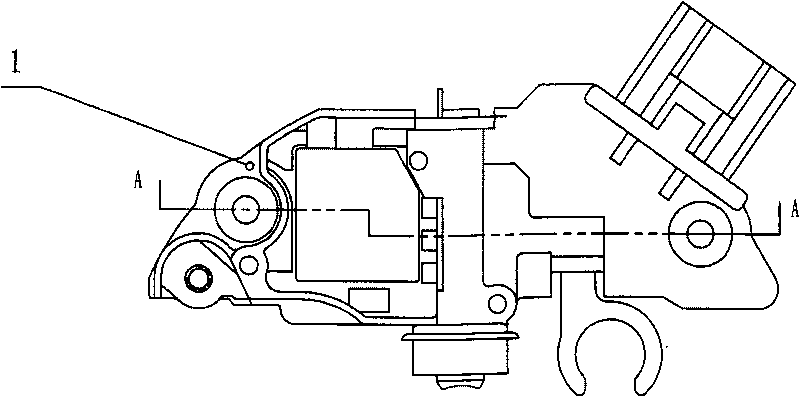

Automotive regulator bracket structure

InactiveCN101764564AReduce assembly processSpeed up the assembly processElectric generator controlCooling/ventilation/heating modificationsMaterial resourcesEngineering

The invention discloses an automotive regulator bracket structure and belongs to automotive regulators. The automotive regulator bracket structure consists of a bracket and a radiating plate. The automotive regulator bracket structure is characterized in that: the radiating plate is arranged on the bracket, embedded in plastic and integrated into a whole with the plastic bracket. The radiating plate is used as a mold insert of the plastic bracket in advance, and is put into an injection mold, and the regulator bracket is molded into a whole through an injection molding machine. During assembling the regulator, the radiating plate assembly process can be saved; a great deal of labor and material resources are saved; and the assembly process is greatly improved. Because the periphery of the radiating plate is coated with plastics and is combined with the plastics into a whole, the radiating plate cannot separate from the plastics due to long-term vibration. Therefore, the scrap of the regulator due to falling of the radiating plate is avoided.

Owner:张金霞

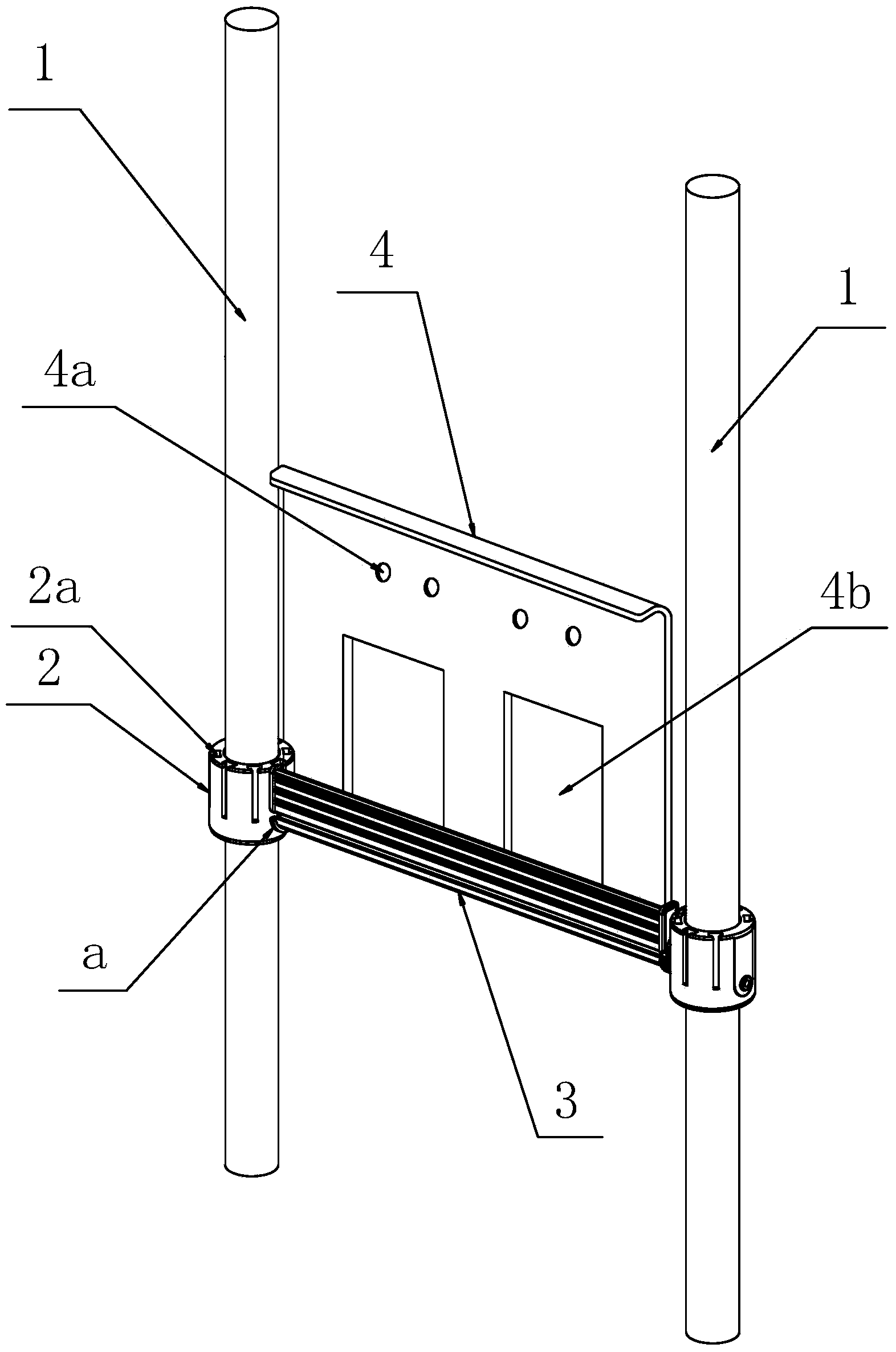

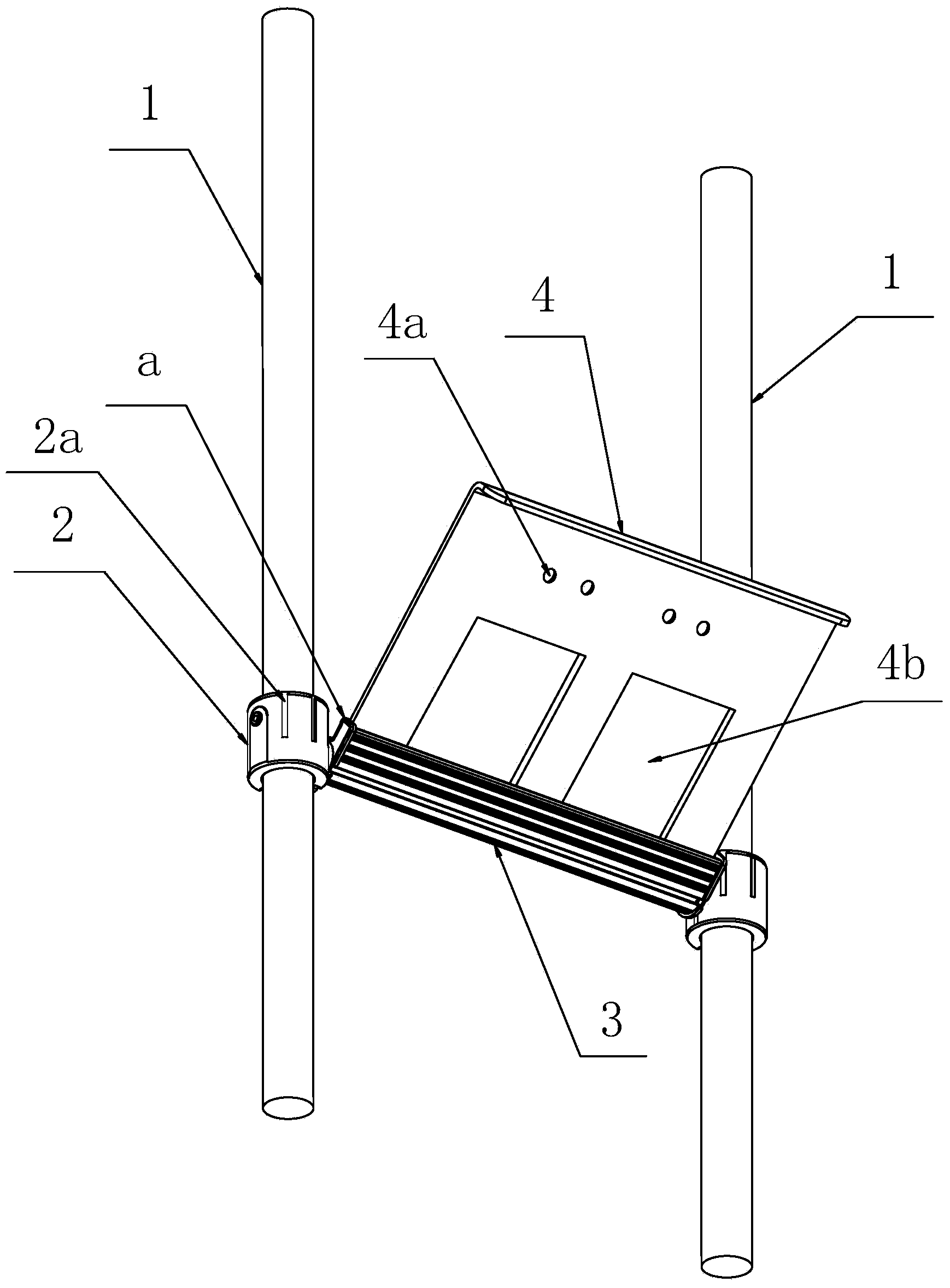

Double-pole positioning mechanism for liquid crystal display screen in exhibition

InactiveCN104358975AImprove layout efficiencySimple structureStands/trestlesElevation angleLiquid-crystal display

The invention discloses a double-pole positioning mechanism for a liquid crystal display screen in an exhibition. The double-pole positioning mechanism comprises two metal vertical poles arranged in parallel, and is characterized in that sleeve joints are respectively arranged on the two metal vertical poles at the same height in a sleeving mode; each sleeve joint is respectively adsorbed and fixed onto the corresponding metal vertical rod by virtue of a plurality of magnetic blocks arranged on the inner wall of the corresponding metal vertical pole. The double-pole positioning mechanism further comprises a support base strip arranged between the two sleeve joints; the two ends of the support base strip are respectively connected with the corresponding sleeve joints rotationally through ratchet self-locking rotating mechanisms; a liquid crystal display screen assembling board is fixed on the support base strip. The double-pole positioning mechanism is simple in structure and convenient to mount, the liquid crystal display screen is conveniently positioned, and the placement height and front and rear elevation angles of the liquid crystal display screen can be flexibly adjusted.

Owner:徐新华

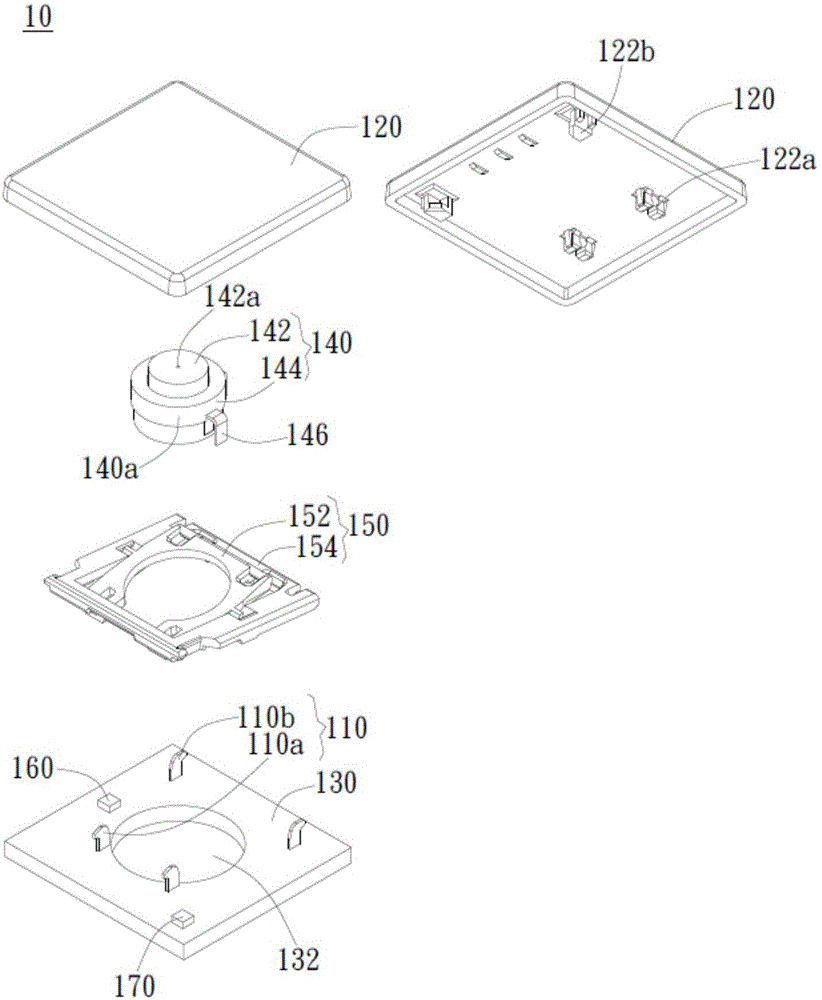

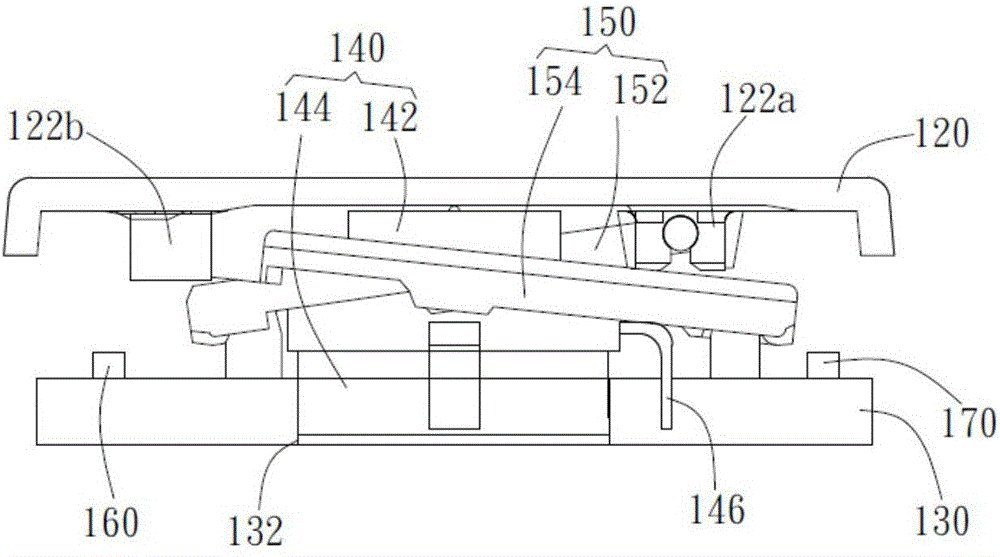

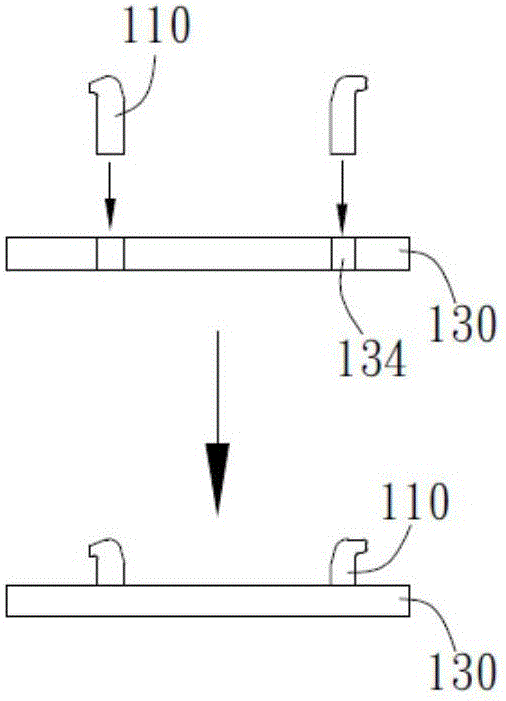

Press key structure

InactiveCN105761990AFunction increaseEasy layout designKey modulesContact operating partsKey pressingElectricity

The invention discloses a press key structure comprising a key cap, a rigid circuit board, at least one coupling member, a micro-switch and a support unit, wherein the key cap is provided with at least one connecting part, the rigid circuit board has an accommodating space, the at least one coupling member is arranged on the rigid circuit board and projects toward the key cap, the micro-switch is positioned below the key cap and is partially accommodated in the accommodating space, the micro-switch is electrically connected to the rigid circuit board, the support unit is coupled to the at least one connecting part and the at least one coupling member, and therefore the key cap can be supported to move relative to the rigid circuit board to trigger the micro-switch. According to the press key structure, through arrangement of the micro-switch, comfortable pressing touch can be realized, the micro-switch is integrated with the rigid circuit board which provides a needed electric path, and therefore feasibility and convenience of individual press key maintenance can be improved. According to the press key structure, the coupling member is integrated with the rigid circuit board, the circuit board is enabled to have a function of a coupling key cap or the supporting unit, no extra base plate is needed, and the number of elements of the press key structure is reduced.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

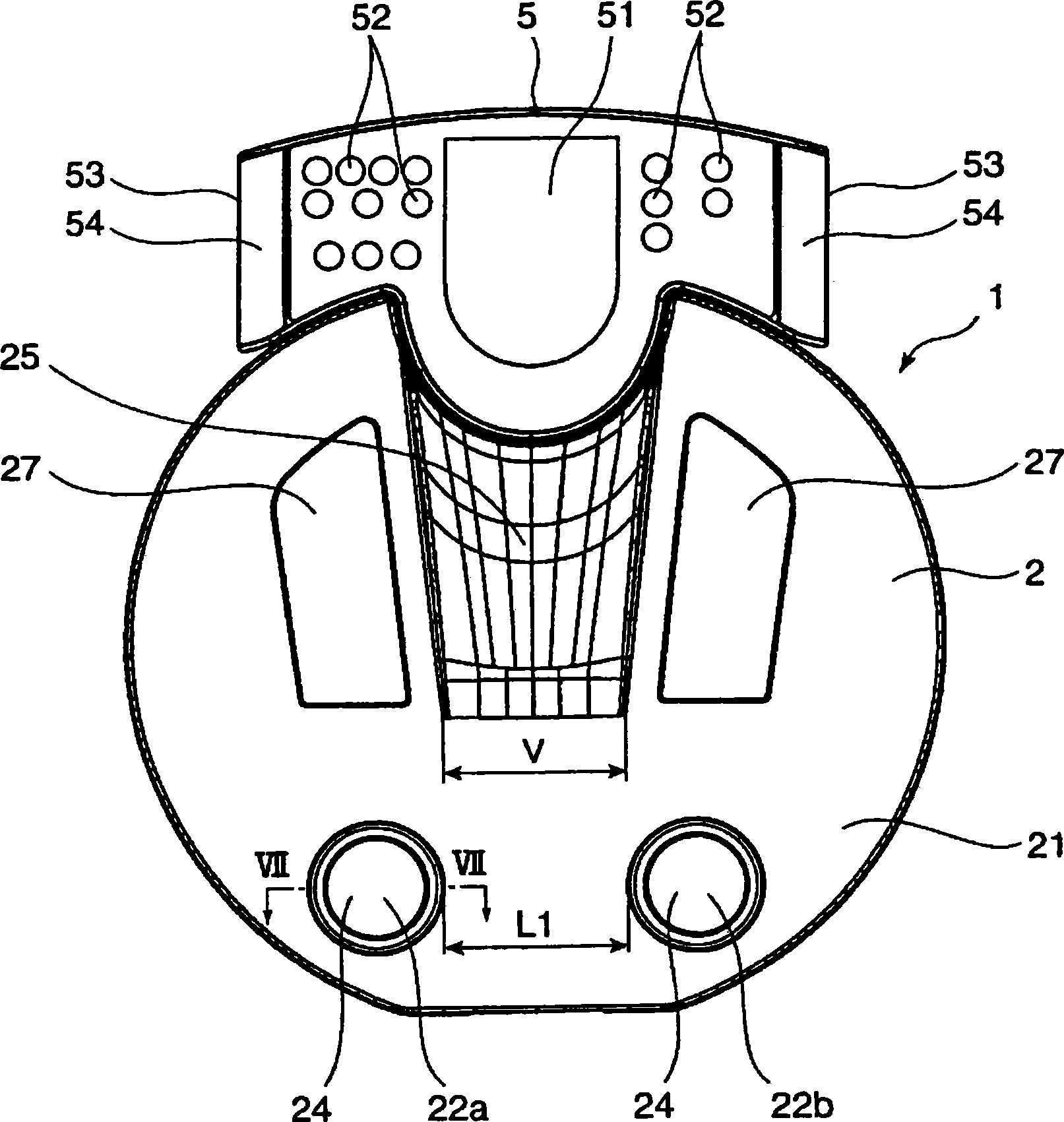

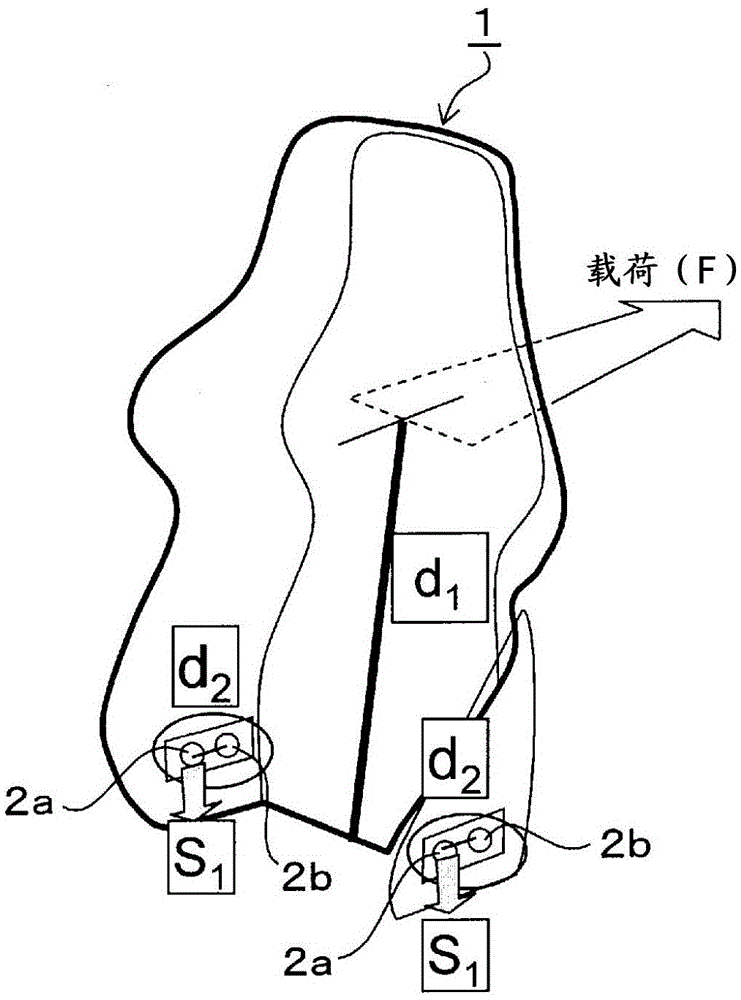

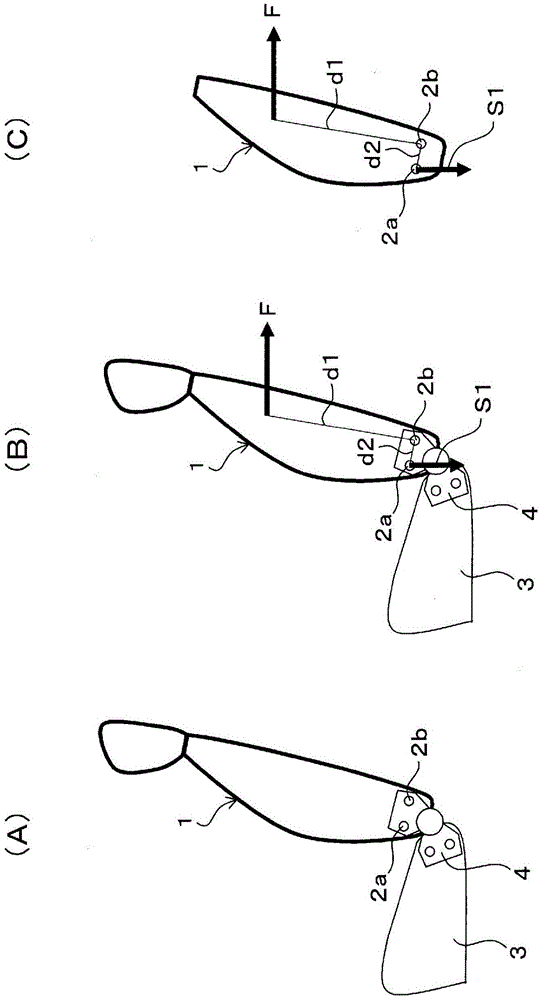

Fiber-reinforced resin structure

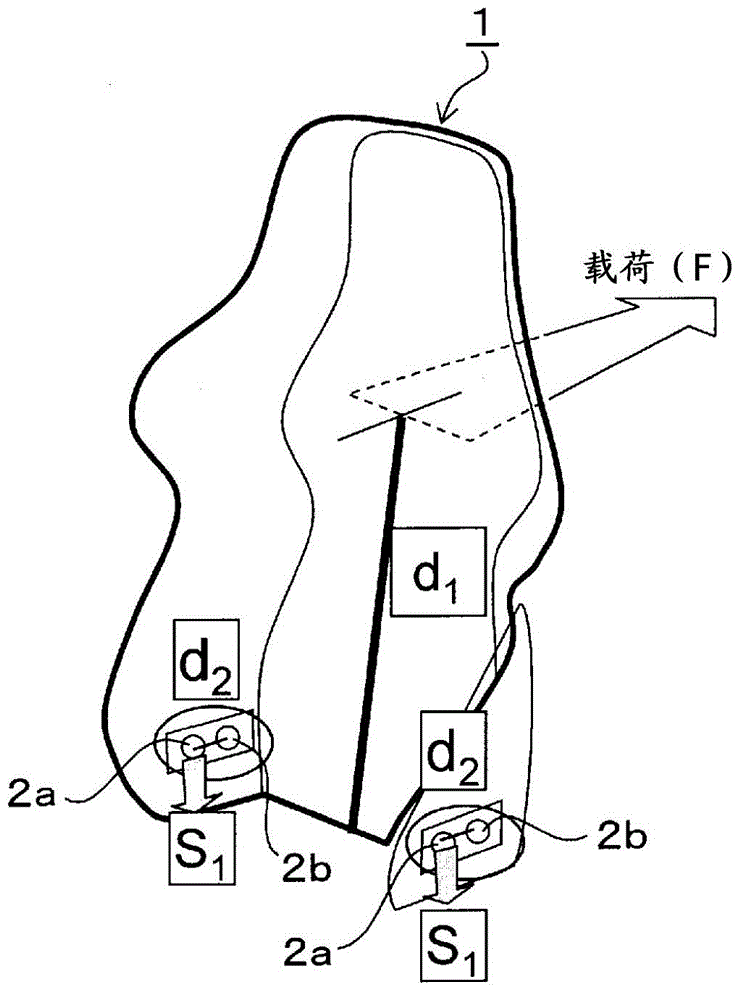

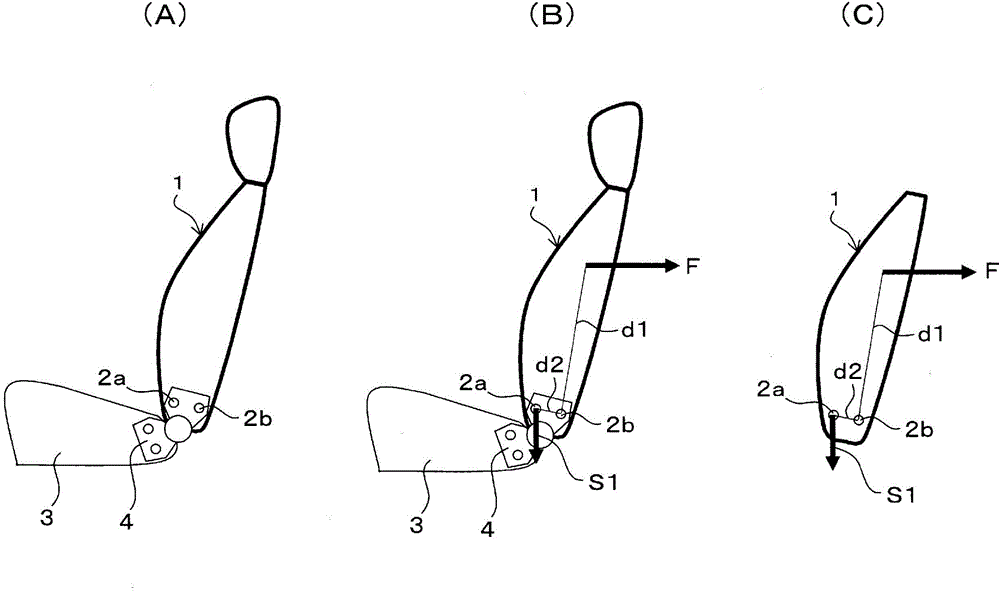

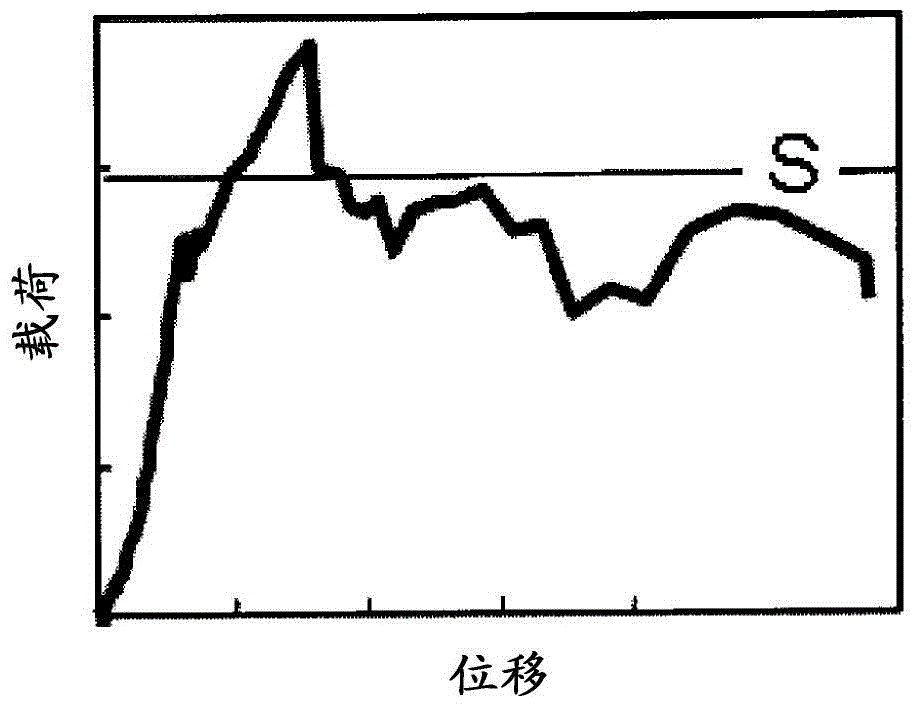

ActiveCN103958267AImprove mechanical propertiesHigh efficiency absorptionBack restsSeat framesEngineeringImpact energy

A fiber-reinforced resin structure having a hole into which a connector that connects to another member is inserted. Said fiber-reinforced resin structure is characterized in that the bearing strength of the part of the inside surface of the hole on which the load from the connector acts, represented by the stress at which deformation of said part starts increasing even without the load acting on said part from the connector increasing, is less than the breaking strength of the fiber-reinforced resin constituting that part of the structure. This makes it possible, without increasing the number of components or assembly steps, for the structure to exhibit good mechanical properties while absorbing external loads such as impact energy with extremely high efficiency via localized deformation or displacement only, with no accompanying breakage.

Owner:TORAY IND INC

Screw multi-channel automatic feeding and installation machine

ActiveCN105666118BAccurate and efficient automatic feedingFlexibleMetal working apparatusEngineeringMechanical engineering

The invention relates to a screw multi-channel automatic feeding and installing integrated machine, and belongs to the field of mechanical manufacturing. A spiral type vibration feeder is arranged in a positioning groove of a supporting frame and fixedly connected with a screw separating device in a threaded mode through a groove type spiral feeding rail. A shell of the screw separating device is fixedly connected with the supporting frame on a vertical feeding system through threads. A workpiece clamping and positioning system is fixedly connected with a base through threads. A vertical feeding transmission system is fixedly connected with the base. A screwdriver screwing mechanism is fixedly connected with the vertical feeding transmission system through threads. One ends of spiral conveying channels are fixedly connected with the screw separating device, and the other ends of the spiral conveying channels are fixedly connected with a screw feeding and screwdriver guiding part. The screw multi-channel automatic feeding and installing integrated machine has the advantages that the structure is novel, the accurate and efficient screw automatic feeding, distributing and assembling work can be conducted, the assembling progress is greatly accelerated, and the assembling efficiency of the system is improved.

Owner:JILIN UNIV

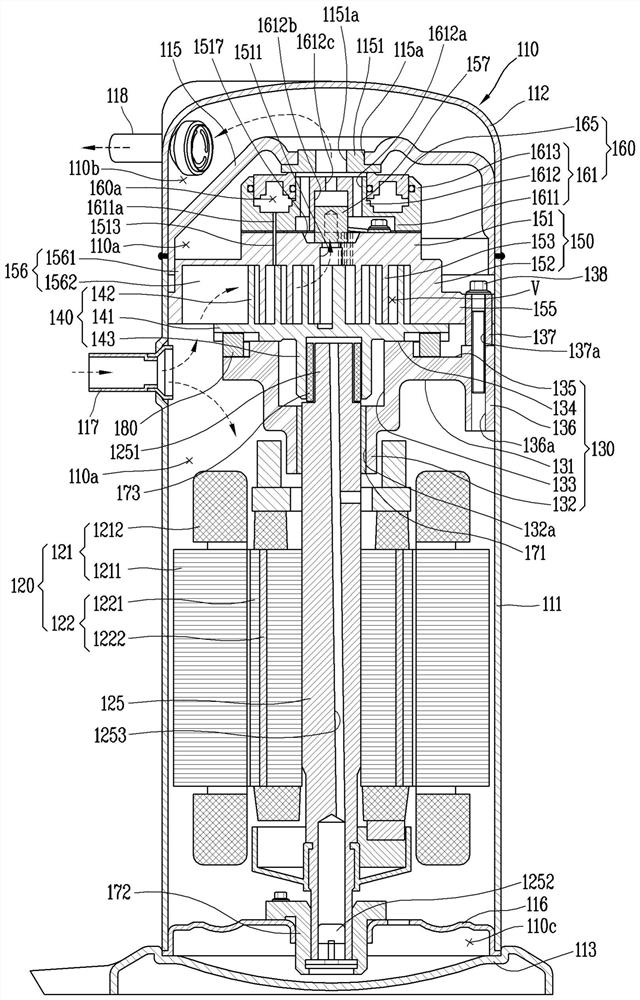

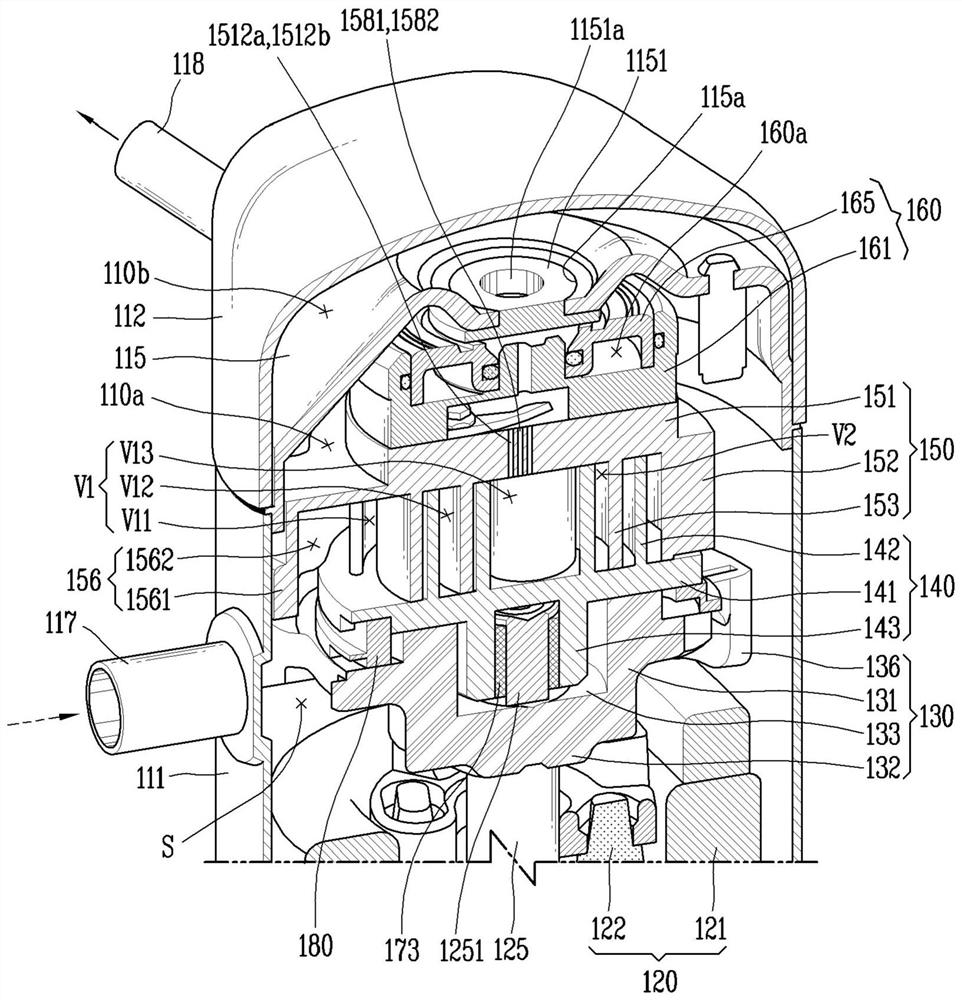

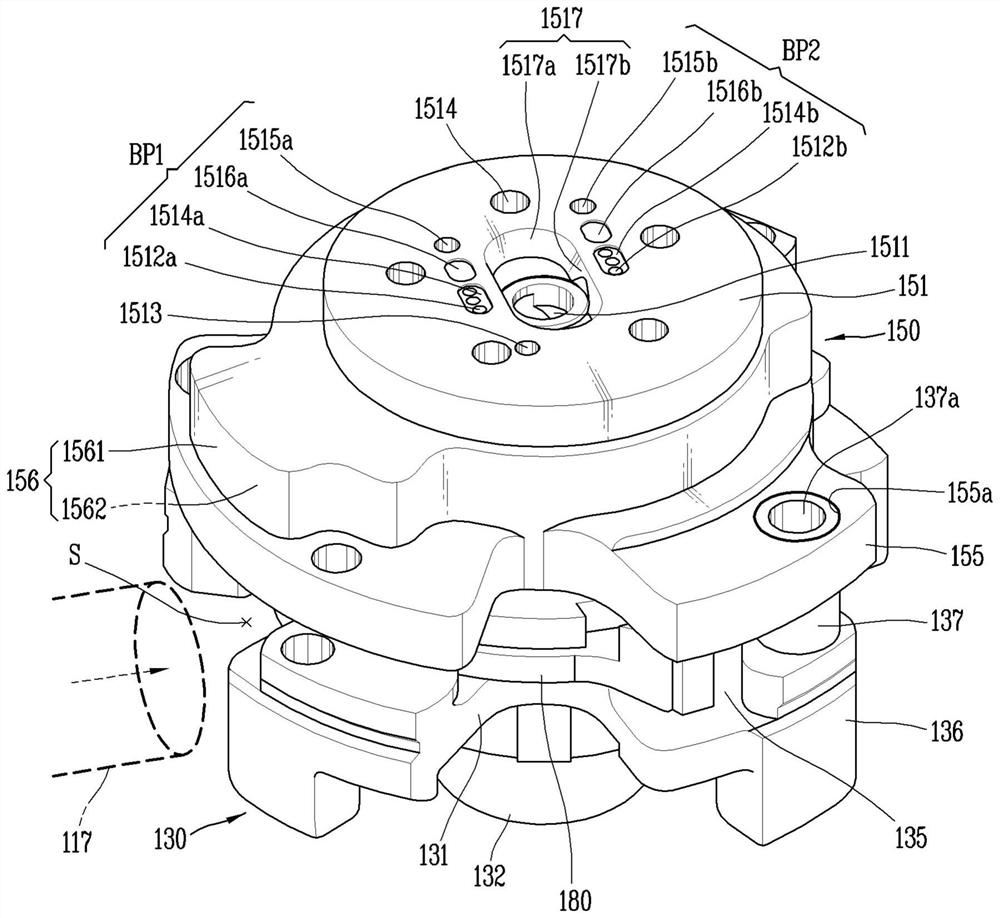

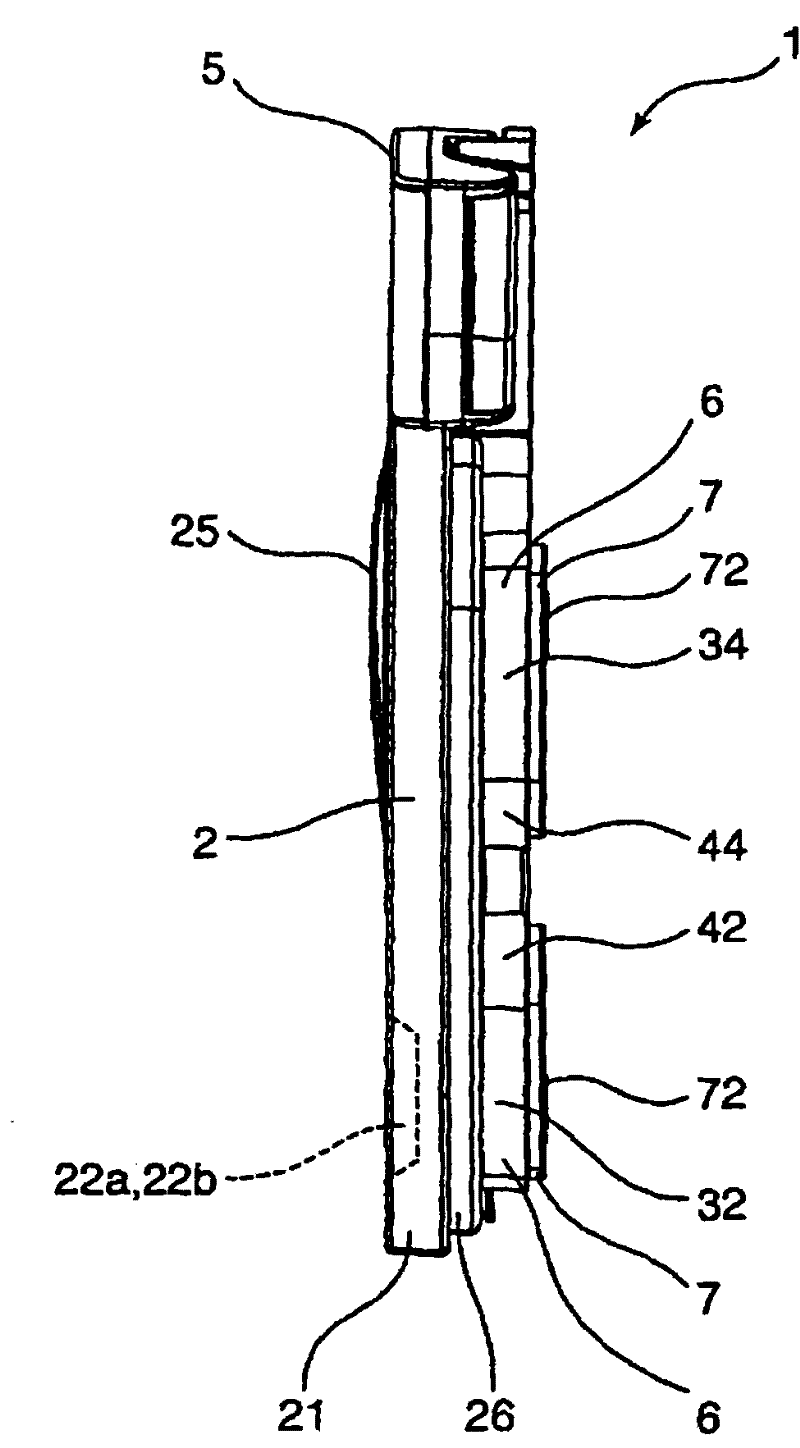

Scroll compressor

ActiveCN113803260ASmall specific volumeReduce manufacturing costRotary/oscillating piston combinations for elastic fluidsWorking fluid for enginesEngineeringDrive motor

A scroll compressor may include a casing having a low pressure portion and a high pressure portion, a suction pipe that communicates with the low pressure portion and a discharge pipe that communicates with the high pressure portion, a drive motor installed inside of the low pressure portion, an orbiting scroll coupled to the drive motor to perform an orbiting motion, a non-orbiting scroll engaged with the orbiting scroll to form a compression chamber, and a refrigerant guide provided on the non-orbiting scroll to guide a refrigerant suctioned into the low pressure portion to be suctioned into the compression chamber, whereby an increase in specific volume of refrigerant suctioned into the compression chamber may be suppressed, and thus, an amount of refrigerant suctioned into the compression chamber may increase, thereby improving efficiency of the compressor.

Owner:LG ELECTRONICS INC

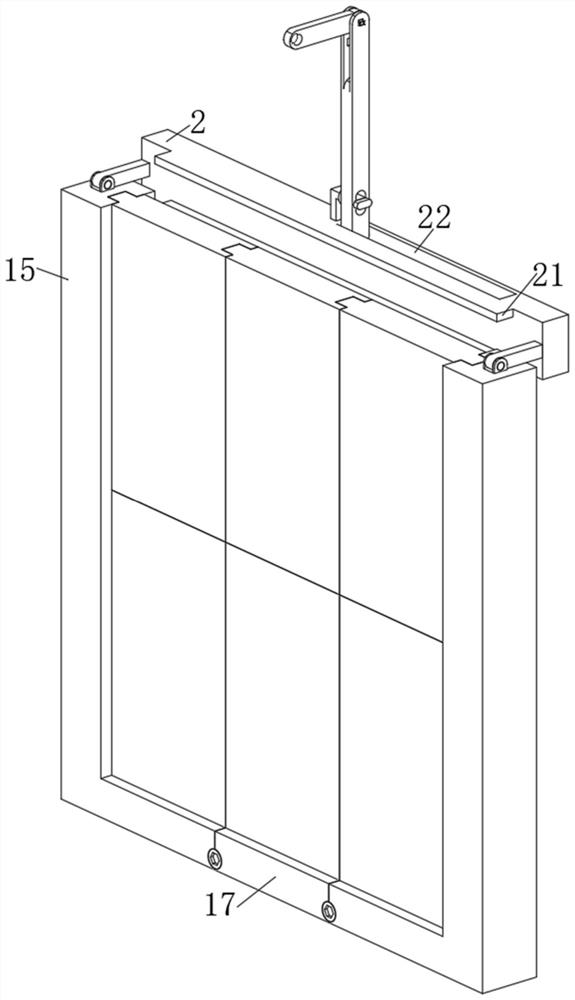

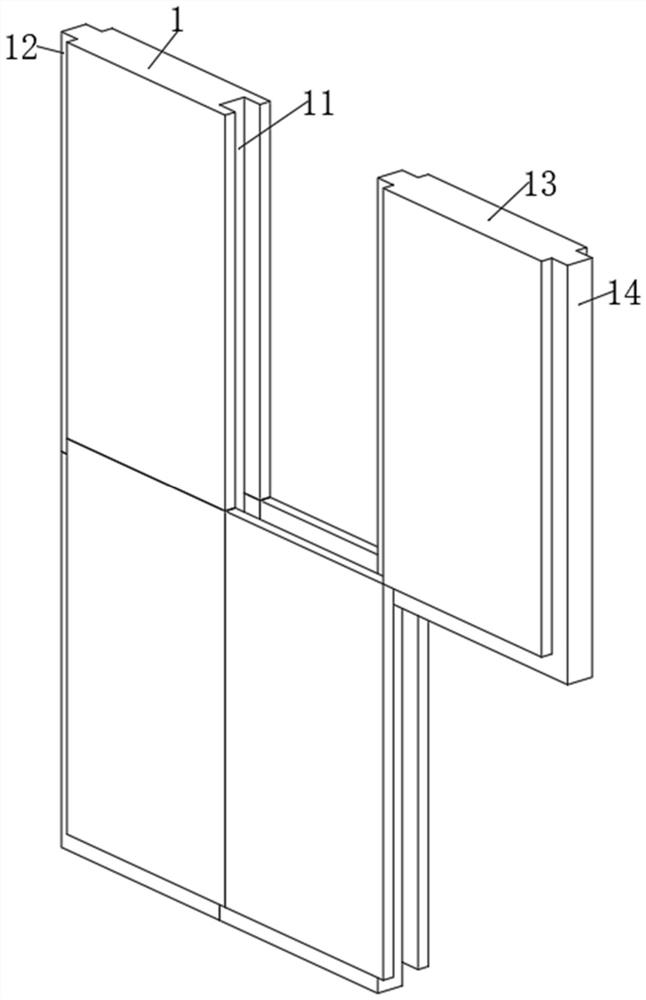

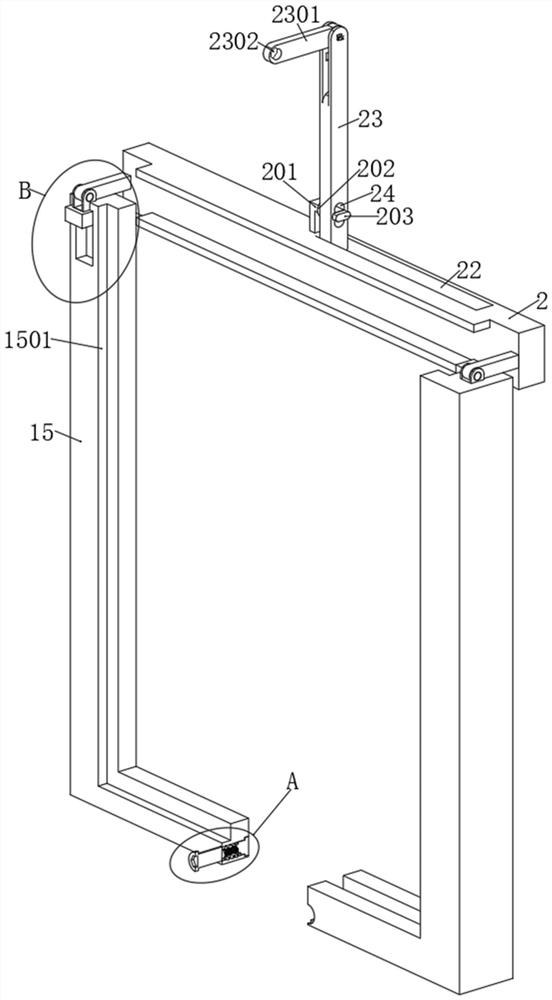

Energy-saving sound insulation and noise reduction partition plate for fabricated building

PendingCN114876082AStable splicingExtended use timePassive housesSound proofingClassical mechanicsStructural engineering

The invention relates to the technical field of fabricated buildings, in particular to an energy-saving sound insulation and noise reduction partition plate for a fabricated building. The sound insulation and noise reduction partition plate assembly comprises a first partition plate, a butt joint groove, a half-protruding plate, a second partition plate, a full-protruding plate and an adjusting outer frame assembly, the adjusting outer frame assembly comprises an outer frame body, a first semicircular groove and an adjusting embedded rod, the butt joint groove is formed in one end of the first partition plate, the half-protruding plate is arranged at one end of the first partition plate, and the second semicircular groove is formed in the other end of the second partition plate. The second partition plate is located on one side of the first partition plate, the full-protruding plate is arranged on the outer side of the second partition plate, so that the outer frame for fixing the partition plate has the function of a hanging rod, and when the partition plate is hoisted, a steel rope only needs to penetrate through the rope penetrating groove, and hoisting of the partition plate can be completed through equipment for winding the steel rope on the ground; and the steel cable support does not need to be built, and the assembly progress of the assembly type building is accelerated.

Owner:深圳华创建筑装饰股份有限公司

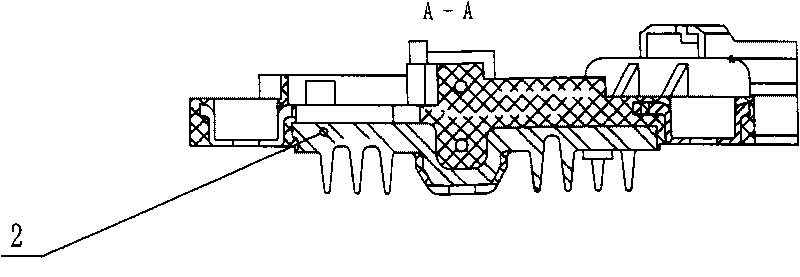

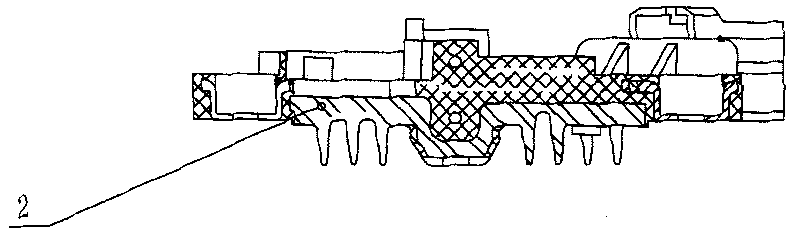

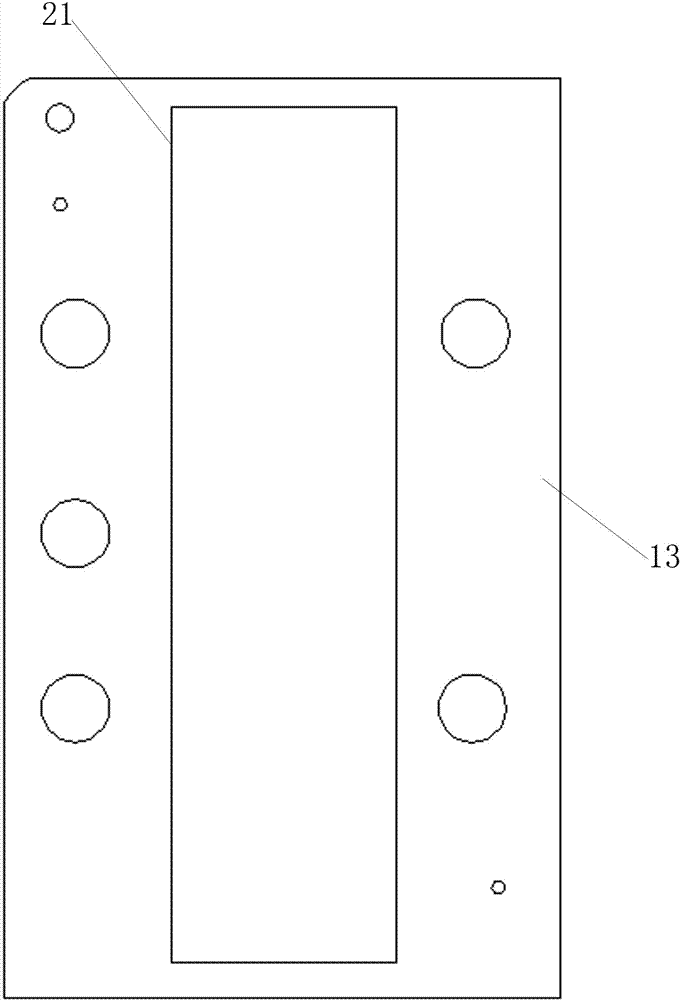

Assembled side-outlet flexible-connection velocity sensor

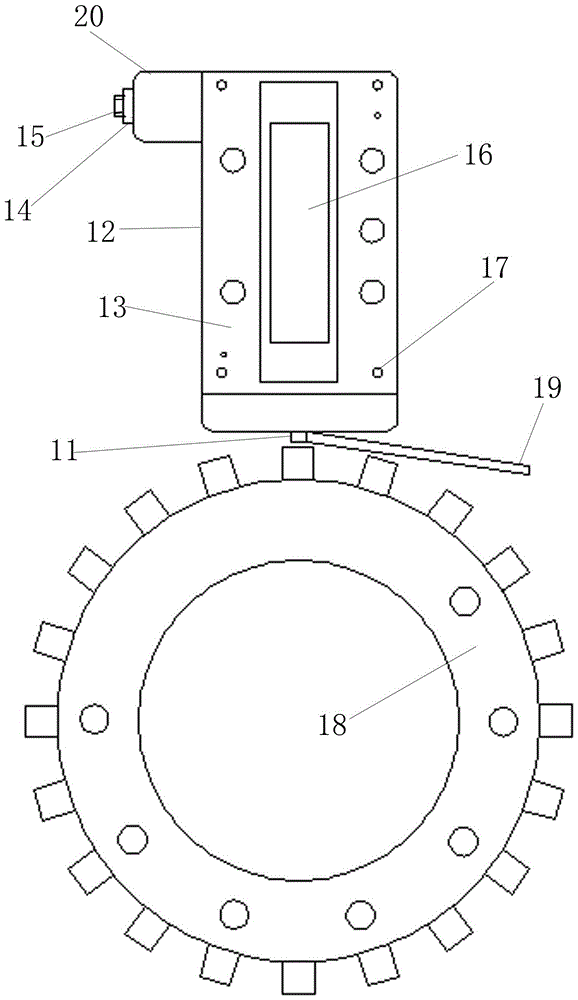

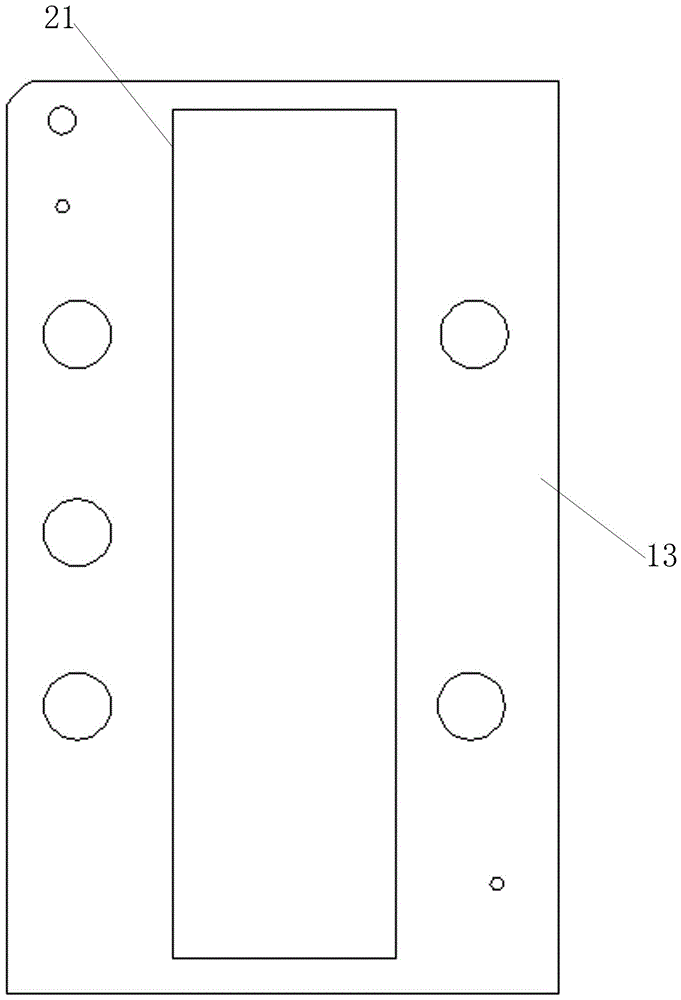

ActiveCN104237550AEasy to assemble and disassembleSpeed up the assembly processSpeed/acceleration/shock instrument detailsEngineeringElectrical and Electronics engineering

The invention relates to a velocity sensor, in particular to an assembled side-outlet flexible-connection velocity sensor which comprises a casing and a closure plate. The casing and the closure plate are combined to form an internal cavity, and a circuit board and flexible connection wires are arranged in the cavity. A boss is horizontally arranged at the position, close to the top surface of the casing, of one side surface of the casing, and is provided with a metal joint horizontally. A cable connected with the circuit board penetrates the metal joint to extend out of the cavity. A sealing rubber sheath is arranged between the inner side of the metal joint and the cable. A probe is mounted at the bottom of the casing and is connected with the circuit board through the flexible connection wires. A sealing pad is sandwiched between the casing and the closure plate. A manufacturing method of the velocity sensor is optimized by means of structural modification, and the technical problems of incapability of reuse and difficulty in repairing when the velocity sensor is in fault are solved.

Owner:CRRC YONGJI ELECTRIC CO LTD

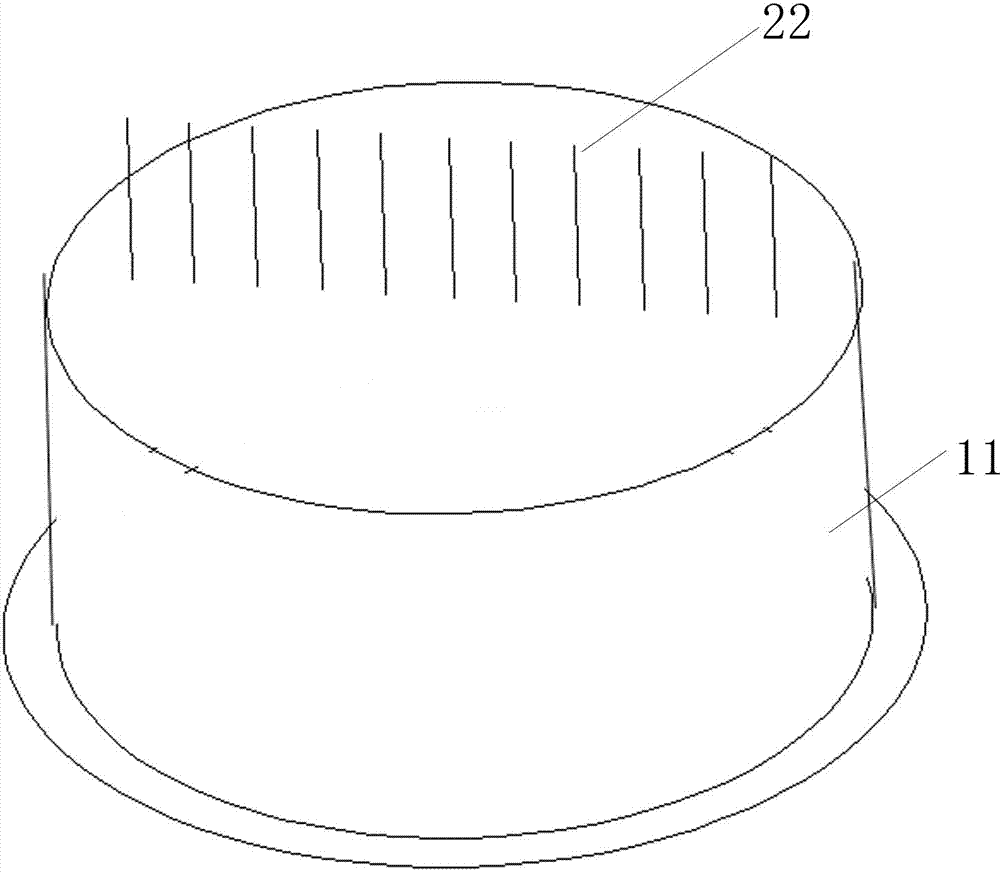

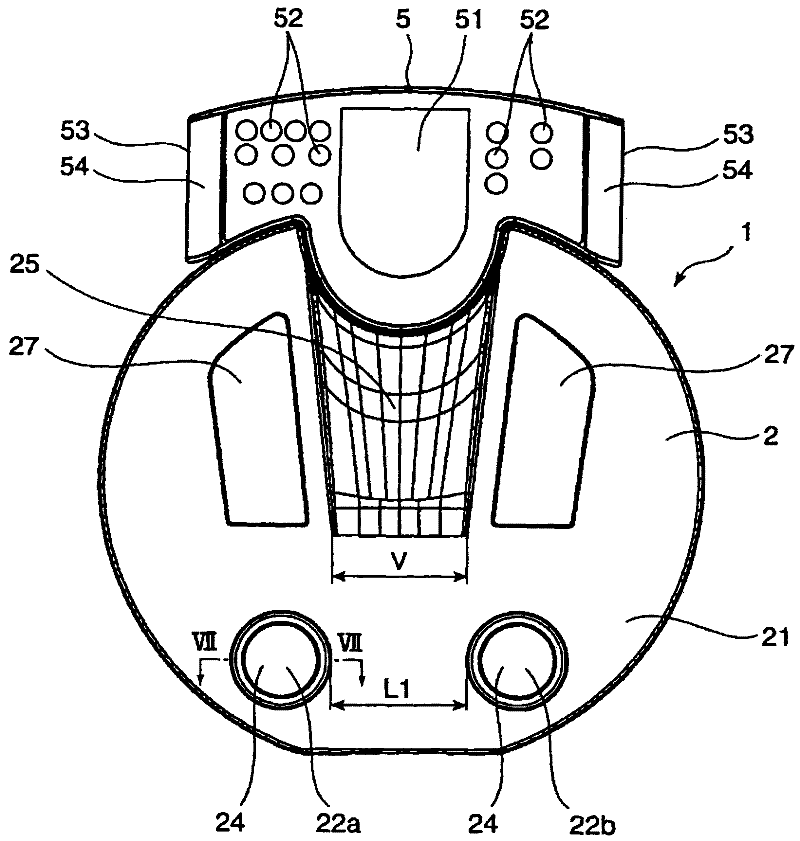

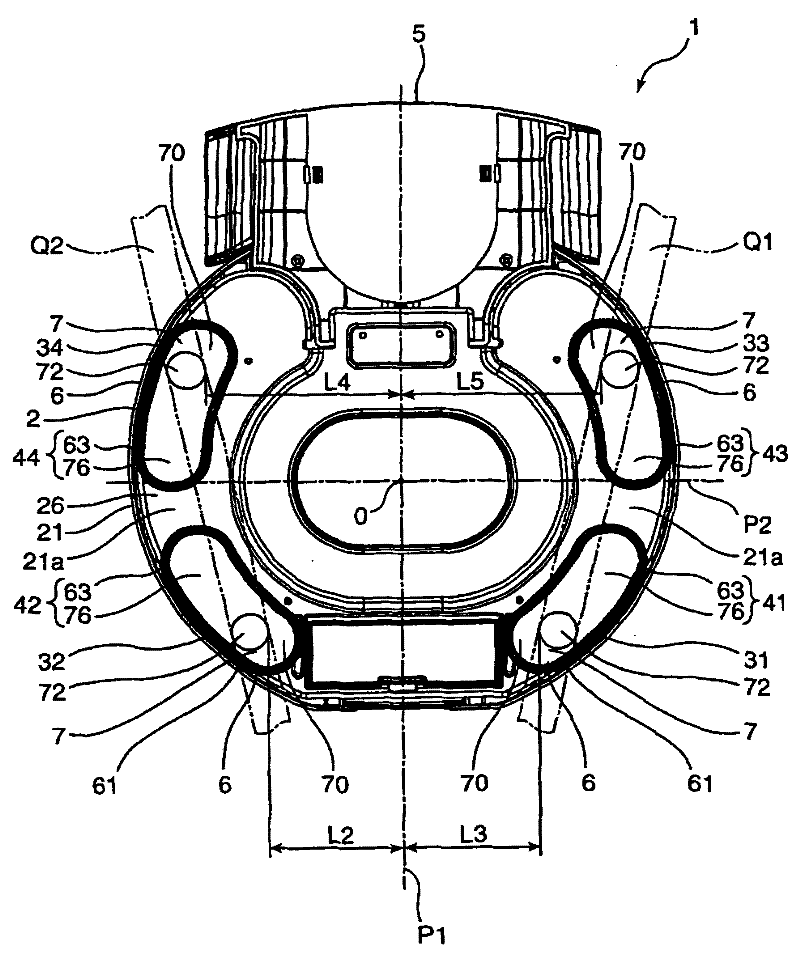

Bathroom scales

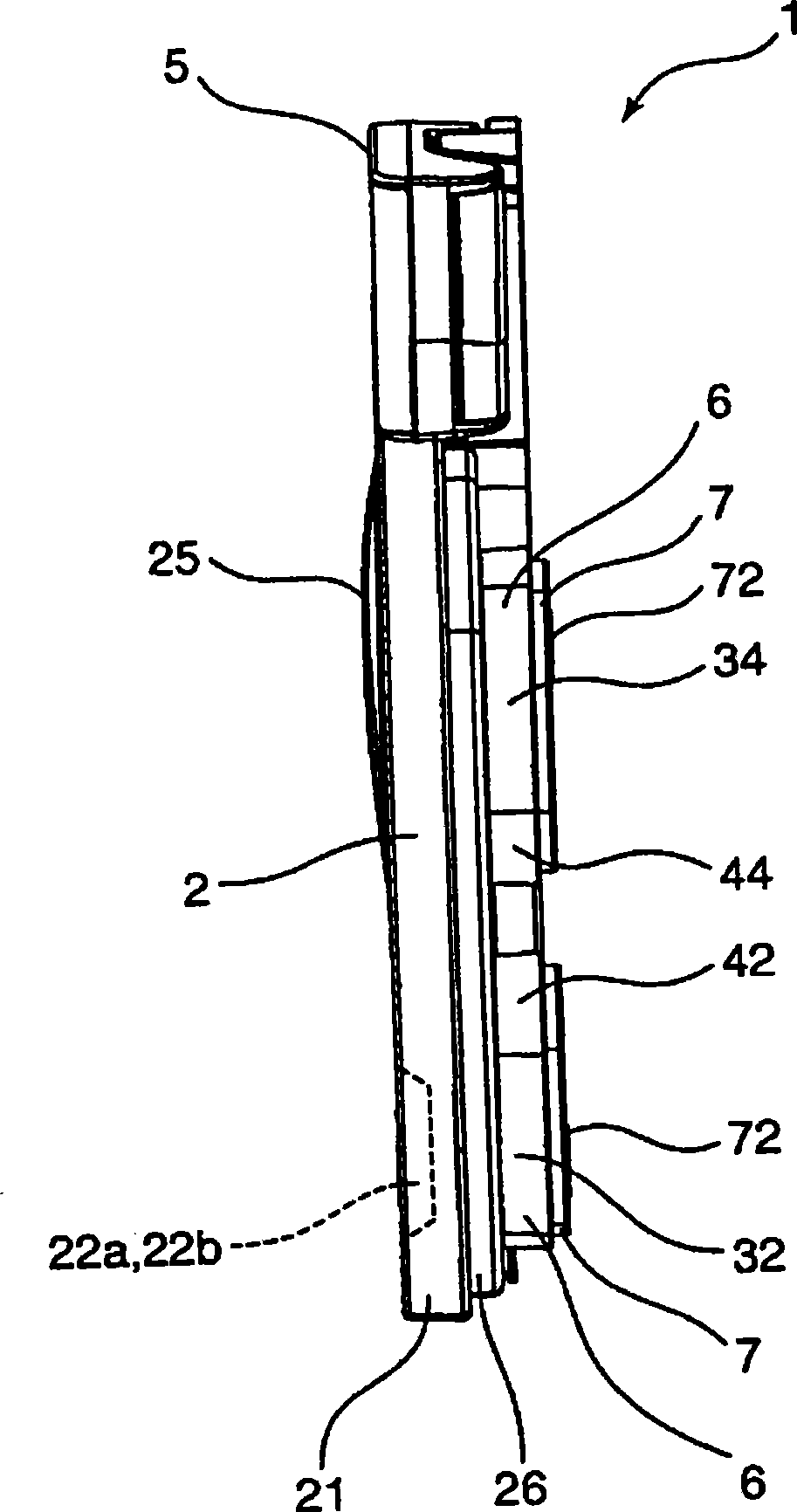

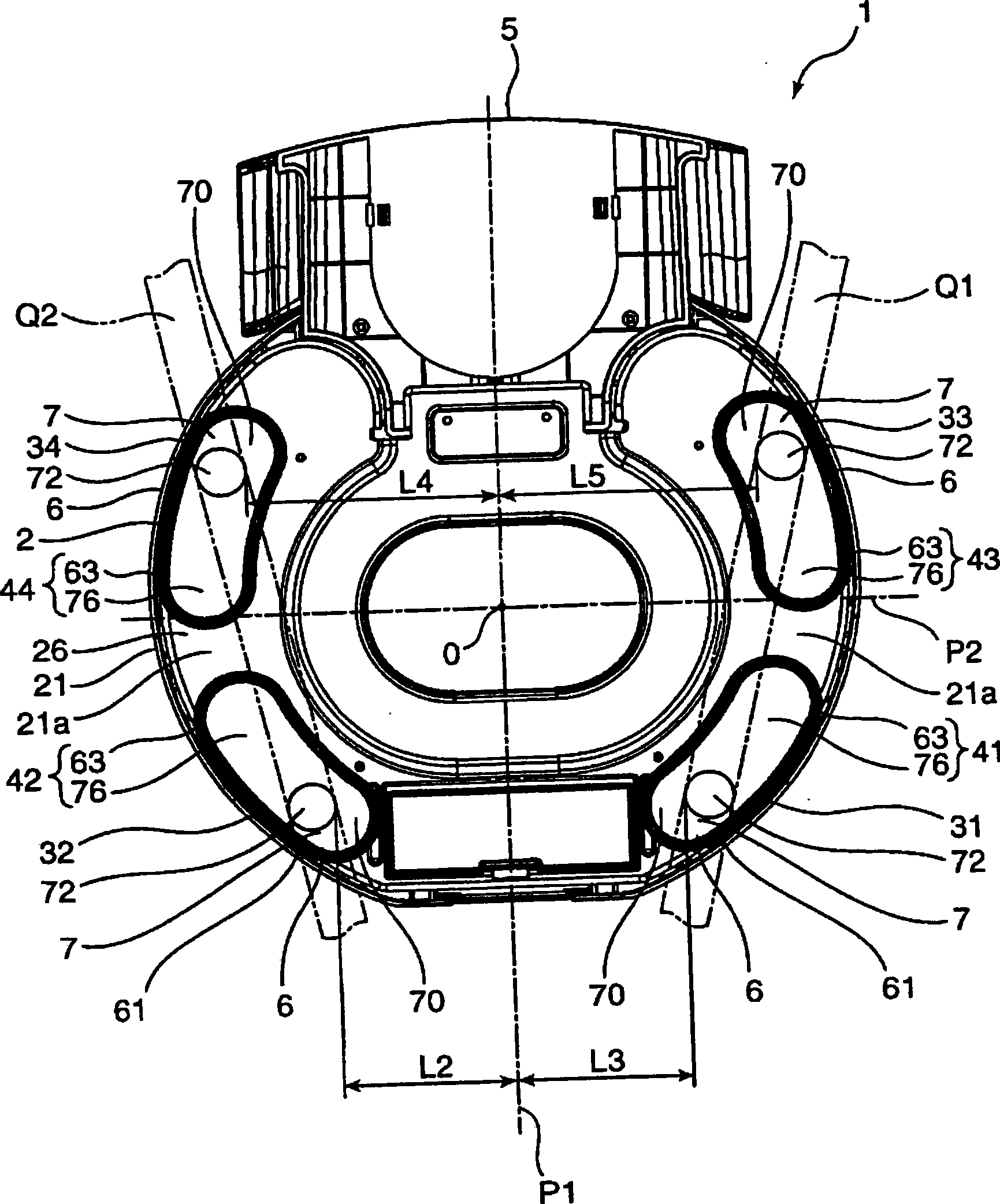

InactiveCN101377434AImprove securityAvoid abnormal noiseSpecial purpose weighing apparatusEngineeringMechanical engineering

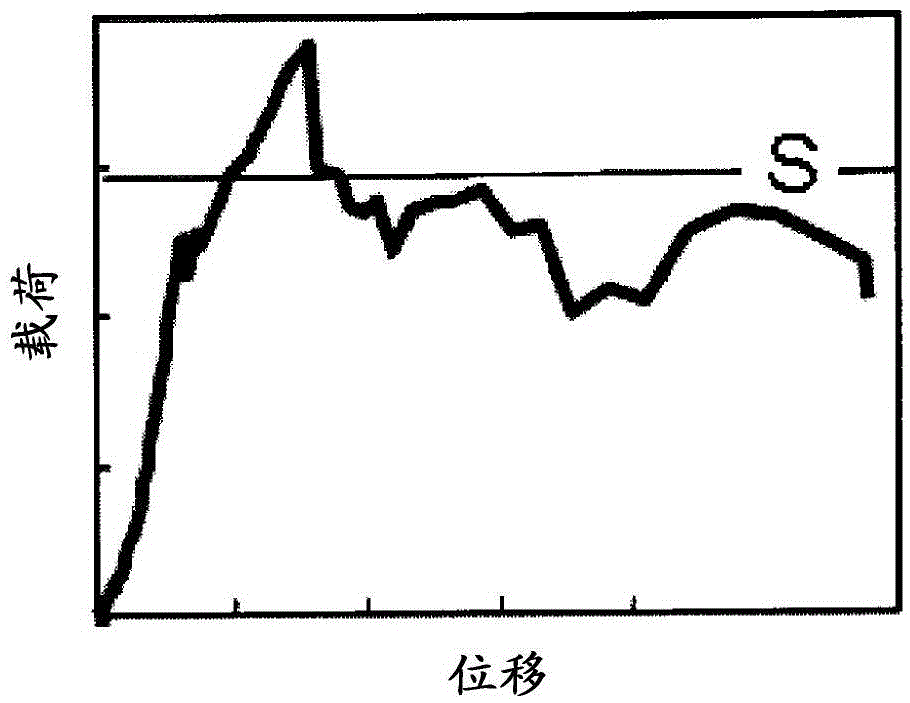

The object of the present invention is to provide a low cost made weighing scale with an incline inhibiting section. The weighing scale includes a scale body (2) with a horse block (21), four feet (31-34), incline inhibiting sections (41-44), as well as show an operation section (5) with a display section. The feet (31-34) include a cylinder (6) and a sensor load-carrying part (7) with a surface abutting section (72). The incline inhibiting sections (41-44) are respectively extending from the cylinder (6) and sensor load-carrying part (7) of the feet (31-34), and are provided below a protruding section (21a) protruding from lines connecting the adjacent surface abutting section (72) on the horse block towards one side of the peripheral.

Owner:MATSUSHITA ELECTRIC WORKS LTD

fiber reinforced resin structure

ActiveCN103958267BExcellent mechanical propertiesIncrease the number ofBack restsSeat framesBreaking strengthPolymer science

The present invention provides a fiber-reinforced resin structure having a hole through which a connector for connecting other members is inserted, wherein the fiber-reinforced resin structure is characterized in that the load on the inner surface portion of the hole on which the load from the connector acts The strength is smaller than the fracture strength of the fiber reinforced resin constituting the part of the structure, wherein the load-bearing strength is expressed as, even if the load from the connecting member acting on the inner surface part of the hole does not increase, the inner surface part of the hole The displacement also starts to increase at the stress. Without increasing the number of parts and assembly processes, the structure can exhibit high mechanical properties, and the fiber-reinforced resin structure itself can not be broken, and the impact energy can be absorbed extremely efficiently only through local deformation or displacement and other loads applied from the outside.

Owner:TORAY IND INC

A prefabricated concrete building connection structure

ActiveCN110924536BEnsure connection stabilitySpeed up the assembly processProtective buildings/sheltersShock proofingEarthquake resistancePipe fitting

The invention discloses an assembled concrete building connection structure, which belongs to the technical field of building structures. The connecting structure includes a first prefabricated component and a second prefabricated component, the end of the first prefabricated component is pre-embedded with a connecting pipe, the second prefabricated component is pre-embedded with a plug-in component that matches the connecting tube, the plug-in component is connected to the The pipe fittings are plugged in, and the plug-in components and the connecting pipes are also fixed as a whole through pouring concrete. The embedded section of the plug-in components includes a tubular shell, a limiter and a perfusion channel. The tubular shell and the perfusion channel are connected by a limiter, and the limiter The fittings are fixed on the inner wall of the tubular shell, the plug-in section is inserted into the connecting pipe fitting, and the embedded section is provided with a concrete pouring port. The connection structure of the present invention is simple in structure and reasonable in design, which improves the overall stability and earthquake resistance of the concrete building; and has low assembly difficulty, without multiple processes such as bolts and welding, which significantly shortens the construction period and reduces construction costs.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Acoustic devices and electronic equipment

ActiveCN110446139BLower resonance frequencyAdjustable volumeSingle transducer incorporationLoudspeaker screensVibrating membraneLow frequency band

The invention discloses an acoustic device, comprising: a sounding unit, the sound waves on the front side of the vibrating diaphragm radiate to the outside through the sound outlet; the rear side of the vibrating diaphragm forms a first airtight cavity, and the first airtight cavity A mounting hole is opened on the wall of the cavity, a flexible deformation part is provided on the mounting hole, a second closed cavity is provided outside the first closed cavity, and the flexible deformed part is arranged in the second closed cavity. The sound wave generated during deformation is sealed in the second airtight cavity; a protective cover plate located outside the flexible deformation part is also provided on the installation hole, and the protective cover plate and the flexible deformation part An avoidance space for avoiding the vibration of the flexible deformation part is formed between them; a plurality of air-permeable micro-holes are opened on the protective cover, and the area of each air-permeable micro-hole is less than or equal to 0.2mm 2 . The acoustic device in the present invention can effectively reduce the resonance frequency, and greatly improve the low-frequency sensitivity of the product as a whole.

Owner:GOERTEK INC

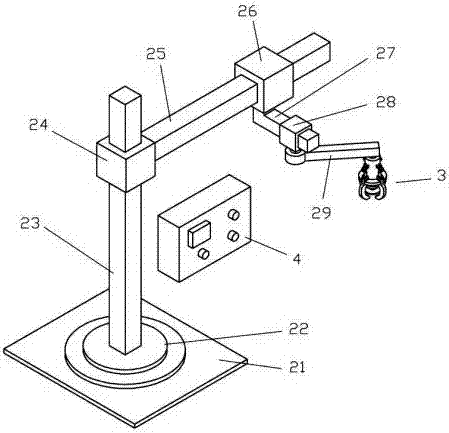

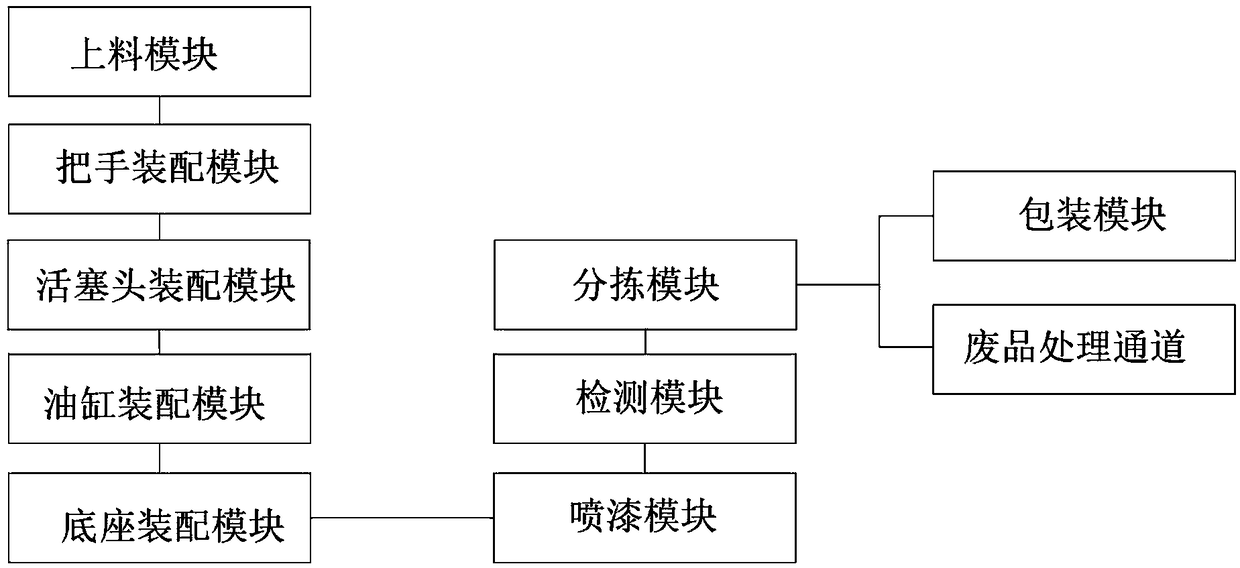

Automated production line of vehicle-mounted refrigerators

InactiveCN107598568ASpeed up the assembly processHigh speedAssembly machinesProduction lineEngineering

The invention provides an automated production line of vehicle-mounted refrigerators. The automated production line comprises an outer shell, a cover body, a tank body and a production line body, wherein the cover body is divided into a left tank cover and a right tank cover which are fixed above the outer shell; the tank body is arranged inside the outer shell, and divided into a first storage tank and a second storage tank; partition plates are arranged inside both the first storage tank and the second storage tank; a compressor is arranged at the inner bottom of the outer shell; a conveyingbelt, a mechanical arm and conveying wheels are arranged on the production line body; the outer shell is placed on the conveying belt; a color mark is arranged at the middle of the inner wall of theouter shell; the conveying wheels are arranged on two sides of the outer shell; the mechanical arm is arranged above the conveying belt; and a position indicator is arranged on the mechanical arm. Theautomated production line provided by the invention is simple in structure, convenient to operate, and convenient to implement, and has the advantages that the production of the vehicle-mounted refrigerators can be quickly completed, the production efficiency can be increased, and the production quality can be improved.

Owner:GUANGDONG INDELB ENTERPRISE CO LTD

Assembled side outlet soft connection speed sensor

ActiveCN104237550BEasy to assemble and disassembleSpeed up the assembly processSpeed/acceleration/shock instrument detailsEngineeringElectrical and Electronics engineering

Owner:CRRC YONGJI ELECTRIC CO LTD

A cu-nb composite wire straightening device

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

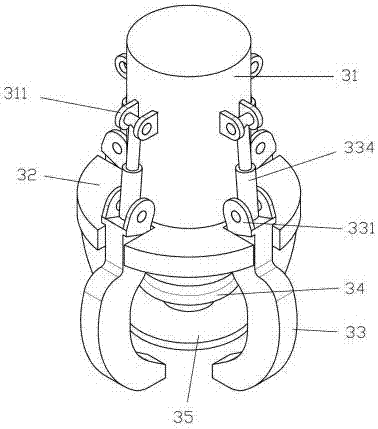

Conveying device for relay electronic elements

PendingCN106944804AImprove adaptabilityRealize orderly deliveryMetal working apparatusTransmission beltMulti degree of freedom

The invention discloses a conveying device for relay electronic elements. The conveying device comprises an independent selection conveying line for the relay electronic elements and a multi-degree-of-freedom pickup unit, wherein the independent selection conveying line for the relay electronic elements can carry out independent selection transportation on massive relay electronic elements; the multi-degree-of-freedom pickup unit is located below one side of the independent selection conveying line for the relay electronic elements, picks up the independently selected relay electronic elements and conveys the independently selected relay electronic elements to the next procedure; the independent selection conveying line for the relay electronic elements comprises a bottom plate and a side plate, the side plate is vertically fixed to the bottom plate, two transmission belt wheels are mounted on the side plate, and the two transmission belt wheels are connected through a conveying belt; and the included angle between the linear conveying direction of the conveying belt and the horizontal direction is 45-60 degrees, and the outer side surface of the conveying belt is uniformly provided with independent selection units. The ordered conveying and pickup of the elements are realized through the independent selection conveying line and the multi-degree-of-freedom pickup unit, convenience is provided for the next assembling process, the assembling progress is accelerated, and the production efficiency is increased.

Owner:苏州格联威智能科技有限公司

Wafer with radiating structure and its production method

ActiveCN101246862BTime consuming to solveImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesActive surfaceMetal

The invention discloses a wafer having a radiating structure, consisting of a wafer and multiple metal radiating parts. The wafer is provided with an active surface and a back surface opposite to theactive surface, wherein the back surface is provided with multiple dead holes. The multiple metal radiating parts are embedded into the head holes, and the metal radiating parts protrude from the backsurface of the wafer.

Owner:ADVANCED SEMICON ENG INC

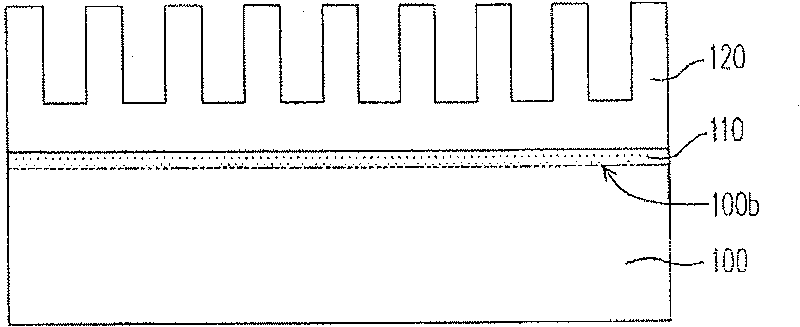

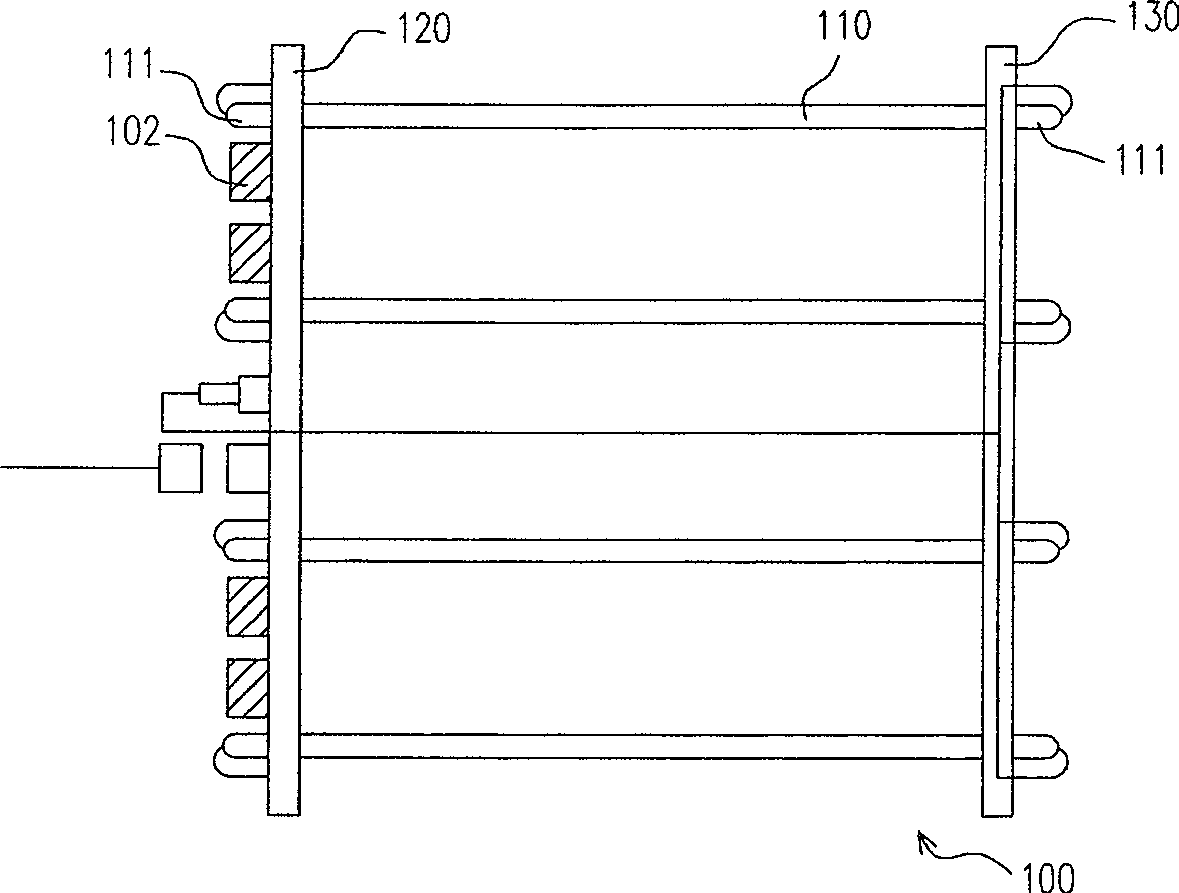

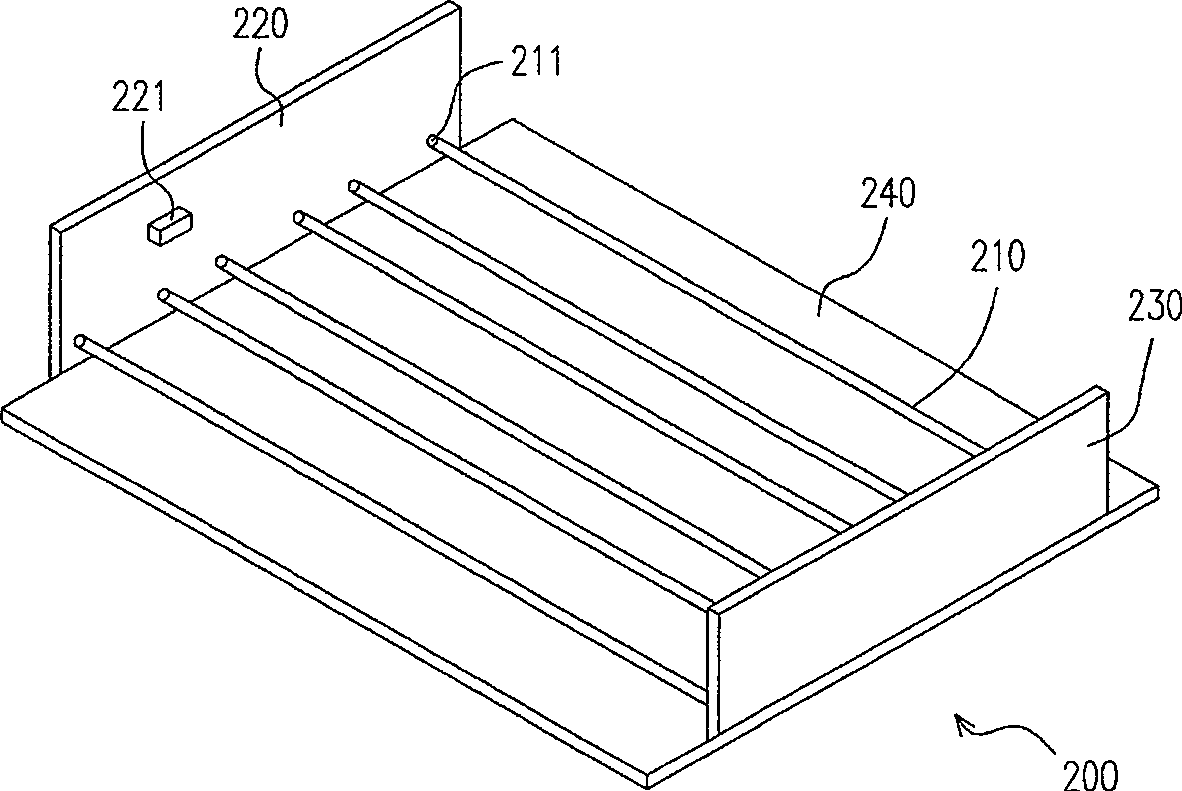

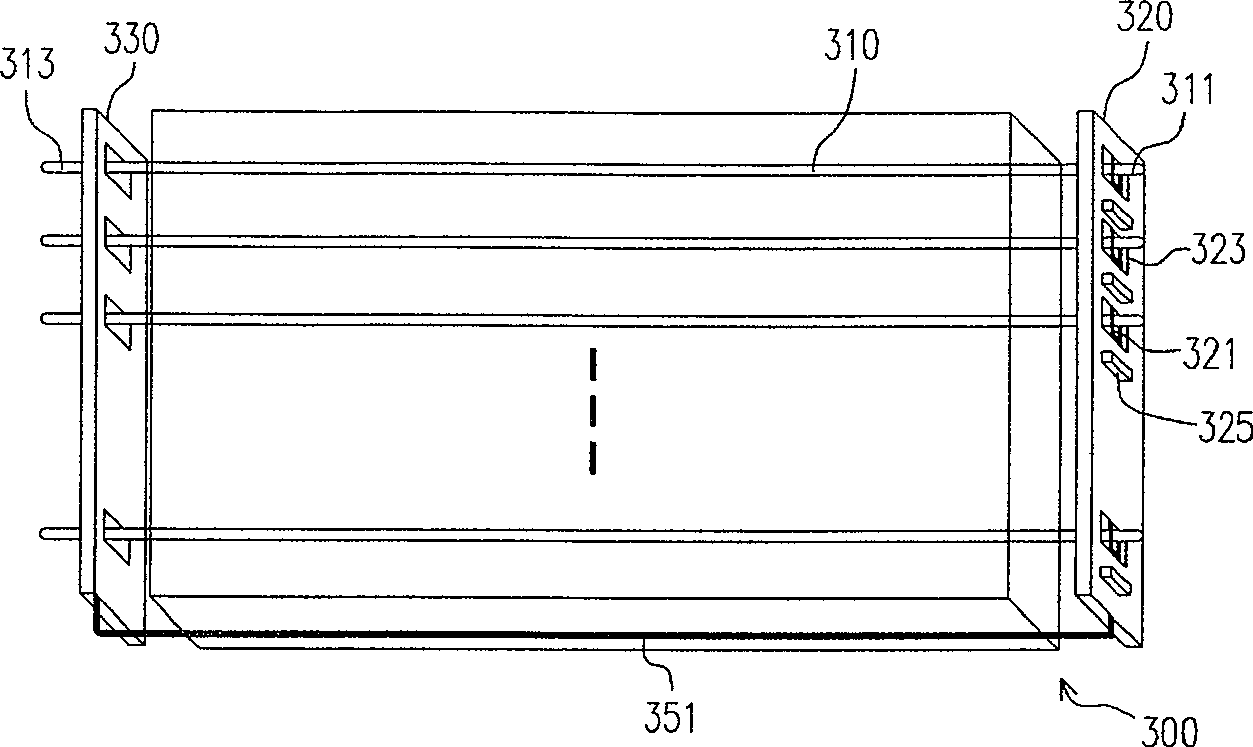

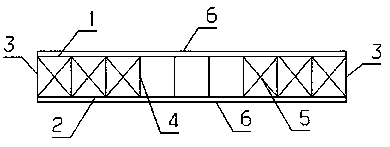

Backlight module

ActiveCN100510902CSpeed up the assembly processReduce manufacturing costStatic indicating devicesPrinted circuitsComputer moduleLamp current

The invention discloses a backlight module, which comprises a plurality of lamp tubes, a first circuit board and a second circuit board. Each lamp has a first electrode and a second electrode. The first circuit board has a plurality of first openings and first conductive clips, wherein the first electrode passes through the first holes and is clamped by the first conductive clips. In addition, a plurality of lamp current adjustment elements are arranged on the first circuit board, and the current adjustment elements are electrically connected to the first electrode through the first conductive clip. In the above-mentioned backlight module, using the first conductive clip or the clamping pin of the current adjustment element to fix the electrode of the lamp tube helps to speed up the assembly process of the backlight module.

Owner:AU OPTRONICS CORP

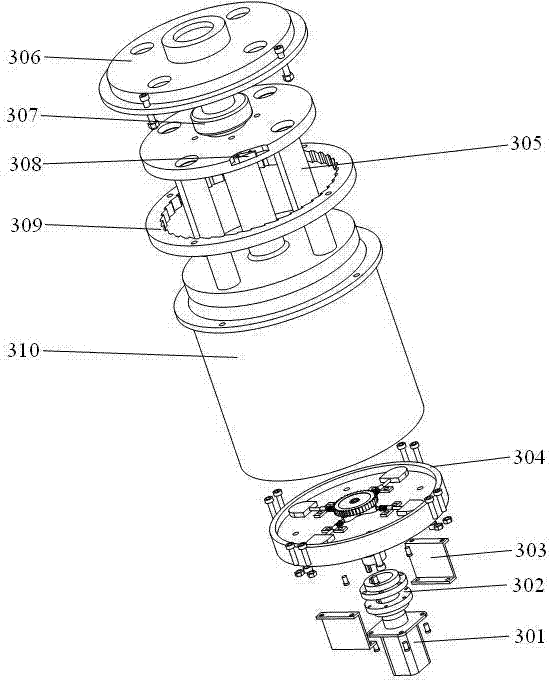

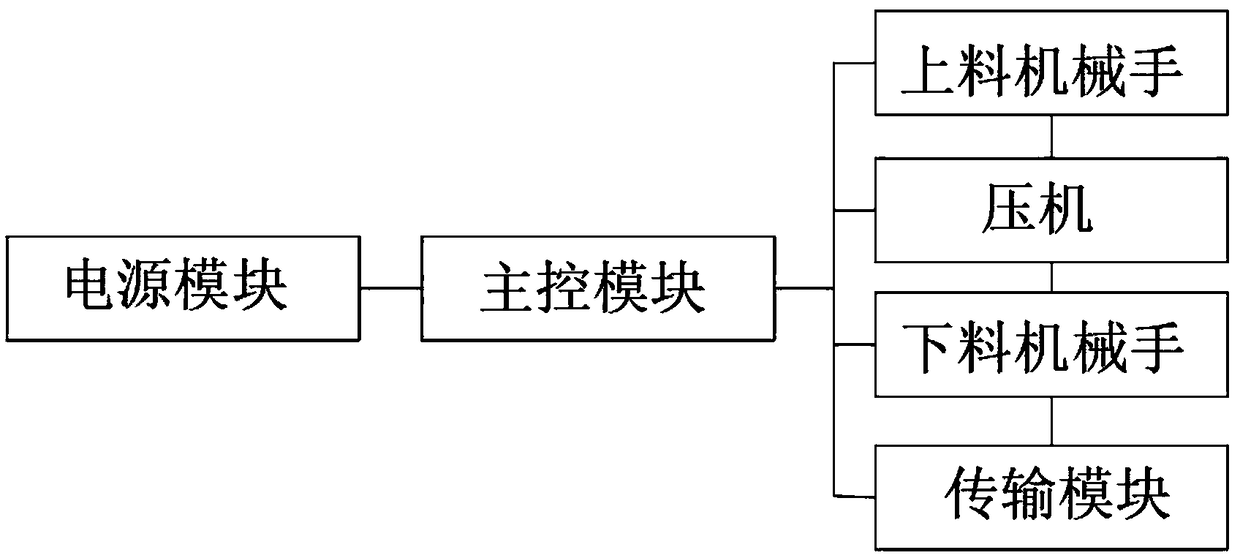

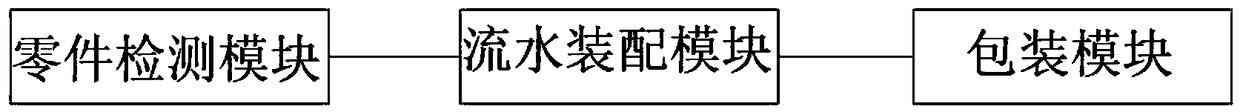

Control system for flexible automatic assembly of hydraulic support column

InactiveCN108994606ASpeed up the assembly processImprove assembly qualityAssembly machinesProps/chocksControl systemComputer module

The invention discloses a control system for flexible automatic assembly of a hydraulic support column. The control system for the flexible automatic assembly of the hydraulic support column structurally comprises a power source module and a master control module. The master control module is connected to the master control module through a cable. The master control module controls a feeding mechanical arm, a press machine, a discharging mechanical arm and a conveying module. The press machine is arranged below the feeding mechanical arm. The discharging mechanical arm is arranged below the press machine. The conveyance module is arranged below the discharging mechanical arm. The feeding mechanical arm is controlled by a feeding module. A handle assembly module is arranged below the feeding module. A piston head assembly module is arranged below the handle assembly module. An oil cylinder assembly module is arranged below the piston head assembly module. A base assembly module is arranged below the oil cylinder assembly module. The control system for flexible automatic assembly of the hydraulic support column improves the assembly progress and the assembly quality, can sense theoperation condition of an assembly line module in time and is simple in structure and convenient to implement.

Owner:田洪志

Hollow plastic formwork capable of significantly increasing supporting force

InactiveCN109403617ALow costStable supportForming/stuttering elementsStructural engineeringEngineering

The invention discloses a hollow plastic formwork capable of significantly increasing the supporting force. The hollow plastic formwork includes an upper formwork, a lower formwork and two side formworks, which define a hollow cavity. A plurality of vertical reinforcing ribs are uniformly arranged in the hollow cavity to define a plurality of through holes in the hollow cavity. X-shaped reinforcing ribs are arranged in through holes with the number accounting for one third of the total number and on the left side, and X-shaped reinforcing ribs are arranged in through holes with the number accounting for one third of the total number and on the right side. Coating layers are arranged on the upper surface of the upper formwork and the lower surface of the lower formwork. The two side formworks are provided with mutually matched tenons and mortises. The upper formwork, the lower formwork, the side formworks, the vertical reinforcing ribs and the X-shaped reinforcing ribs are integrally formed. The hollow plastic formwork increases the support force of the hollow plastic formwork, eliminates the influence of sunlight on the hollow plastic formwork and simplifies the splicing process ofhollow plastic formworks.

Owner:宿迁市正祥新材料股份有限公司

Scales

InactiveCN101377434BImprove securitySimplify the manufacturing processSpecial purpose weighing apparatusMechanical engineeringLoad carrying

The object of the present invention is to provide a low cost made weighing scale with an incline inhibiting section. The weighing scale includes a scale body (2) with a horse block (21), four feet (31-34), incline inhibiting sections (41-44), as well as show an operation section (5) with a display section. The feet (31-34) include a cylinder (6) and a sensor load-carrying part (7) with a surface abutting section (72). The incline inhibiting sections (41-44) are respectively extending from the cylinder (6) and sensor load-carrying part (7) of the feet (31-34), and are provided below a protruding section (21a) protruding from lines connecting the adjacent surface abutting section (72) on the horse block towards one side of the peripheral.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com