Novel wind power generation precast concrete tower component seaming structure and method

A technology of prefabricated concrete and reinforced concrete, which is applied in the direction of wind turbine components, wind turbines, engines, etc., can solve the problems of difficulty in meeting the rapid construction requirements of wind farms, and the long construction period of cast-in-place concrete towers, so as to speed up the assembly progress, Reduce design difficulty and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

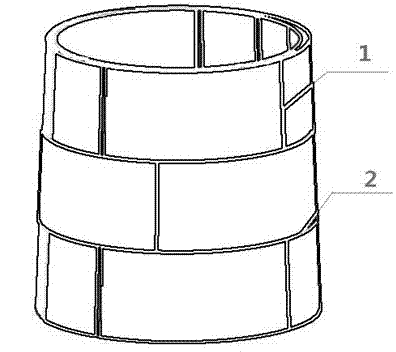

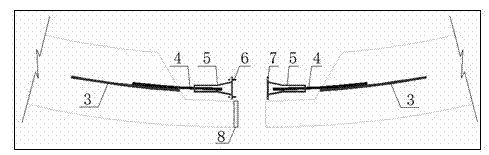

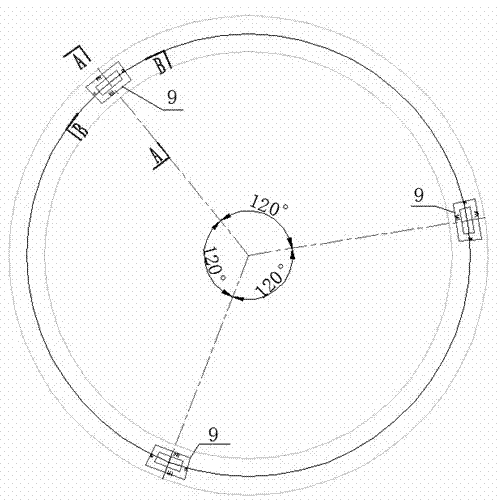

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a new joint structure of prefabricated concrete tower frame components for wind power generation, it at least includes: longitudinal joints 1 and transverse joints 2 between prefabricated reinforced concrete tower frame components for wind power generation, anchor steel plates 3, high-strength bolts 4, sleeves Tube 5, fixing bolt 6, fixing nut 7 and waterproof glue 8; each prefabricated reinforced concrete tower frame member has an anchoring steel plate 3 extending to the longitudinal joint 1 in the horizontal direction, and the anchoring steel plate 3 is connected with one end of the high-strength bolt 4 as a whole; the high-strength bolt 4 The other end is connected to the sleeve 5 through threads, and the sleeves 5 on both sides are fixedly connected by fixing bolts 6 and nuts 7; the upper and lower prefabricated reinforced concrete tower members have positioning key grooves 9 and positioning keys 10 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com