Backlight module

A backlight module and fluorescent tube technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as increased cost, poor connection, and impact on production yield and quality, and achieve the effect of saving production costs and speeding up the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

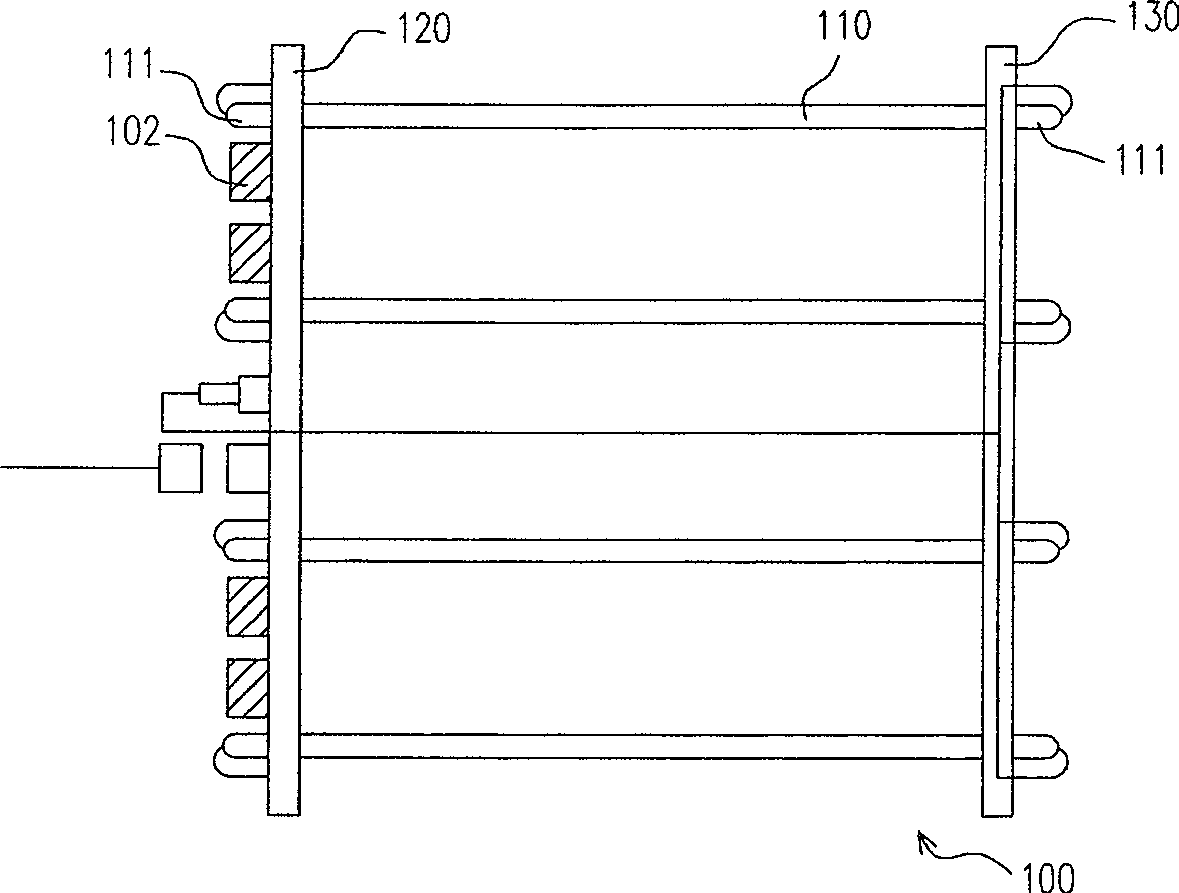

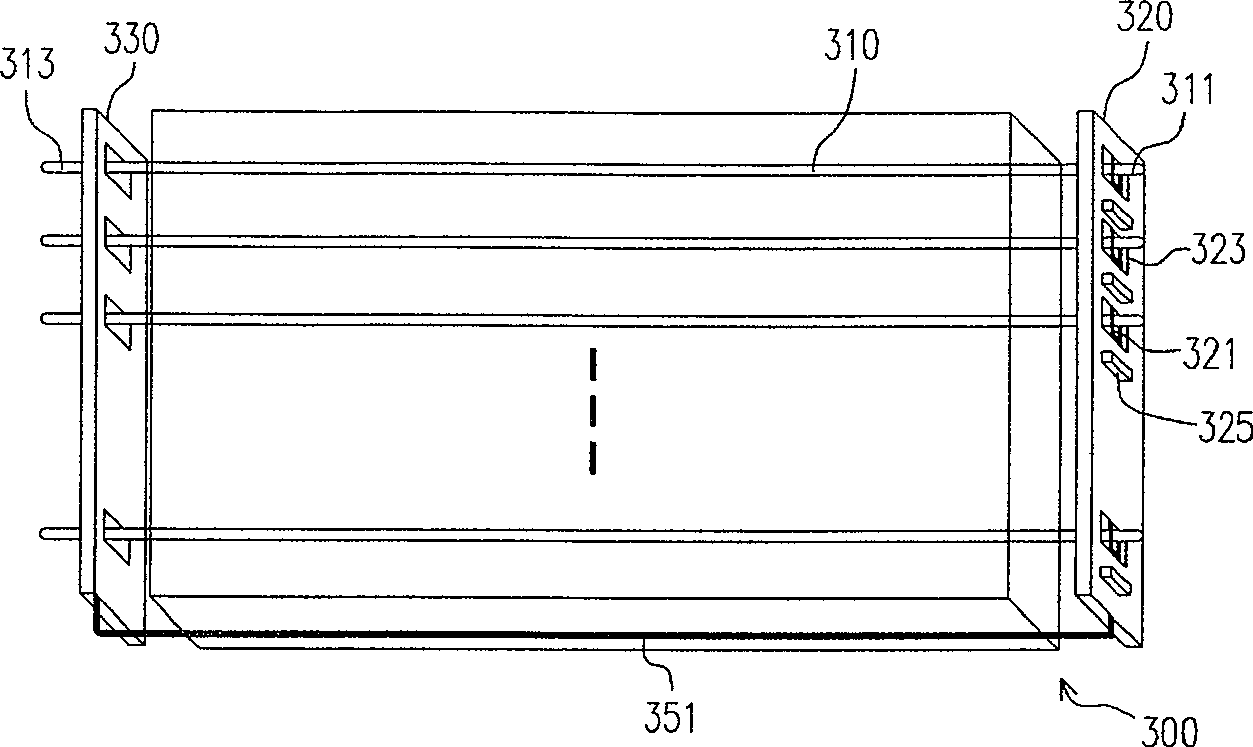

[0096] Figure 3A It is a three-dimensional schematic view of the first embodiment of the backlight module of the present invention. Please refer to Figure 3A , the backlight module 300 includes a plurality of lamp tubes 310 , a first circuit board 320 and a second circuit board 330 , wherein each lamp tube has a first electrode 311 and a second electrode 313 . The first circuit board 320 has a plurality of first conductive clips 321 , and the first conductive clips 321 hold the first electrode 311 . The second circuit board 330 is electrically connected to the second electrode 313 and the first circuit board 320 . In addition, the first circuit board 320 is disposed on one side (eg, the right side) of the backlight module 300 , and the second circuit board 330 is disposed on the other side (eg, the left side) of the backlight module 300 .

[0097] In this embodiment, the lamp 310 can be a CCFL, a Hot Cathode Fluorescent Lamp (HCFL) or an External Electrode Fluorescent Lam...

no. 2 example

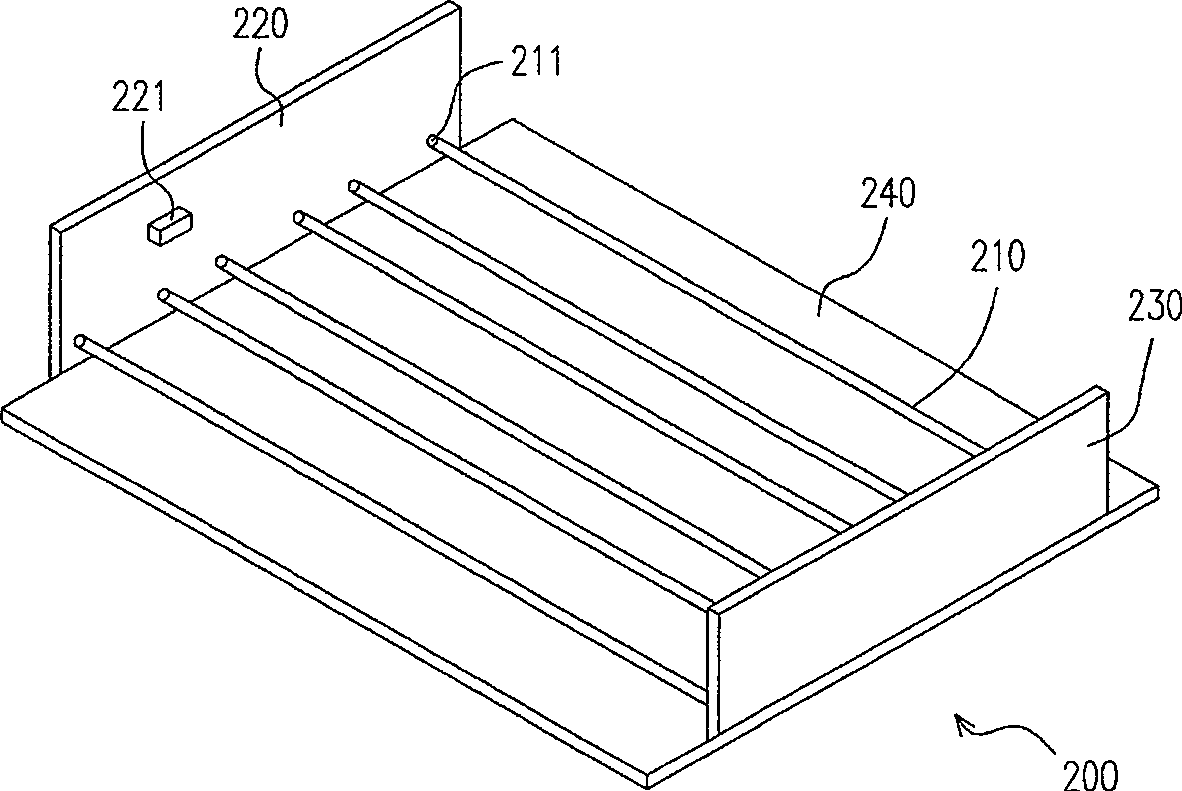

[0109] Figure 5 It is a three-dimensional schematic view of the second embodiment of the backlight module of the present invention. This embodiment is similar to the first embodiment, except that the current adjusting element 525 in the second embodiment has at least one set of clamping pins 525 a for clamping the first electrode 511 .

[0110] Please refer to Figure 5 , the backlight module 500 of this embodiment includes a plurality of lamp tubes 510 , a first circuit board 520 and a second circuit board 530 . Wherein, each lamp tube 510 has a first electrode 511 and a second electrode 513 . The first circuit board 520 has a plurality of current adjustment elements 525 , wherein each current adjustment element 525 has at least one set of clamping pins 525 a for clamping the first electrode 511 . The second circuit board 530 is electrically connected to the second electrode 513 , and the second circuit board 530 can be electrically connected to the first circuit board 52...

no. 3 example

[0114] This embodiment is similar to the first embodiment, but the difference is that the current adjustment element 325 described in the first embodiment is arranged on the first circuit board 320, while the current adjustment element 637 of this embodiment is arranged on the second circuit board 630 .

[0115] Figure 6A and 6B It is a schematic diagram of the second circuit board of this embodiment. Please refer to Figure 6A In this embodiment, the second circuit board 630 has a control circuit 631 , a second conductive clip 633 , a second opening 635 , a current adjusting element 637 and at least one transformer 639 . The current adjusting element 637 is electrically connected to the second electrode 613 of the light tube through the second conductive clip 633 .

[0116] Please refer to Figure 6B In addition to the second conductive clip 633 , the current adjusting element 637 can also directly clamp the second electrode 613 of the lamp tube 610 through at least one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com