Automotive regulator bracket structure

A technology of bracket structure and regulator, which is applied in the structural field of heat dissipation part of automobile regulator bracket, which can solve the problem of uneven bonding force between the plastic bracket part of the regulator and the heat dissipation plate, the difficulty of controlling the uniformity of the glue amount and the curing temperature, and the regulator Scrap and other issues

Inactive Publication Date: 2010-06-30

张金霞

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The curing process of the cooling plate and the plastic bracket requires a large number of personnel and special equipment to participate, and it is difficult to control the uniformity of the amount of glue applied and the curing temperature during the process, which will easily lead to the phenomenon of different bonding forces between the plastic bracket part of the regulator and the cooling plate. , the client used the cooling plate for a long time to disengage the plastic part due to vibration, which directly caused the thick film component to be pulled off and the regulator to be scrapped

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

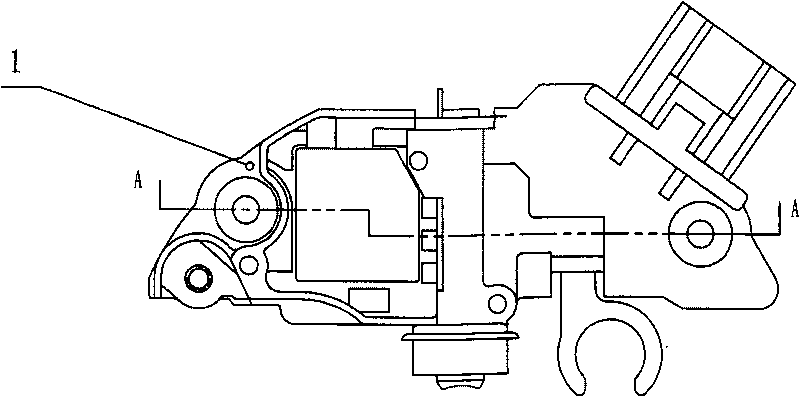

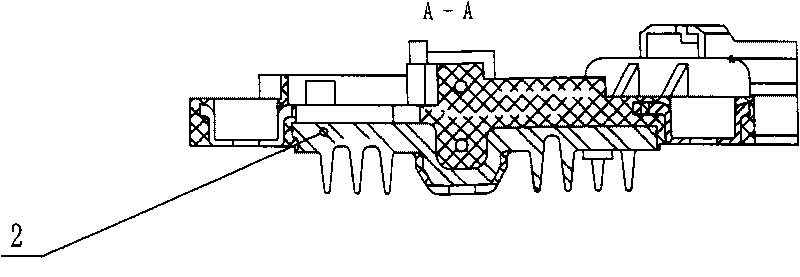

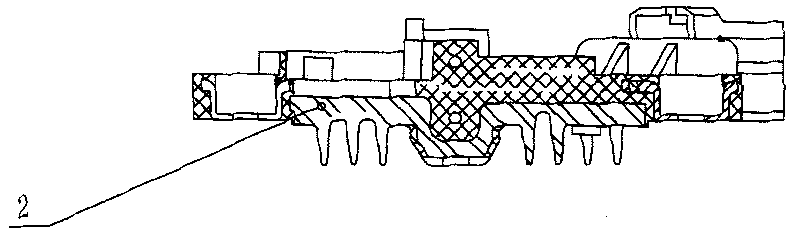

[0010] Embodiment 1: The present invention includes a bracket 1 and a heat dissipation plate 2. The heat dissipation plate 2 is provided on the support 1, and the heat dissipation plate 2 is embedded in plastic to form an integral body with the plastic support. Put it into an injection mold, and inject it into a regulator bracket by an injection molding machine.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an automotive regulator bracket structure and belongs to automotive regulators. The automotive regulator bracket structure consists of a bracket and a radiating plate. The automotive regulator bracket structure is characterized in that: the radiating plate is arranged on the bracket, embedded in plastic and integrated into a whole with the plastic bracket. The radiating plate is used as a mold insert of the plastic bracket in advance, and is put into an injection mold, and the regulator bracket is molded into a whole through an injection molding machine. During assembling the regulator, the radiating plate assembly process can be saved; a great deal of labor and material resources are saved; and the assembly process is greatly improved. Because the periphery of the radiating plate is coated with plastics and is combined with the plastics into a whole, the radiating plate cannot separate from the plastics due to long-term vibration. Therefore, the scrap of the regulator due to falling of the radiating plate is avoided.

Description

technical field [0001] The invention relates to a heat dissipation part structure of an automobile regulator bracket, in particular to an automobile regulator bracket structure. Background technique [0002] At present, the existing automotive regulators all adopt a structure in which the plastic bracket is separated from the heat dissipation plate, and the heat dissipation plate and the plastic need to be cured and bonded together by curing glue. The curing process of the cooling plate and the plastic bracket requires a large number of personnel and special equipment to participate, and it is difficult to control the uniformity of the amount of glue applied and the curing temperature during the process, which will easily lead to the phenomenon that the bonding force between the plastic bracket part of the regulator and the cooling plate is different. , the client used the cooling plate for a long time to disengage the plastic part due to vibration, which directly caused the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02P9/00H02M1/00H05K7/20

Inventor 张金霞

Owner 张金霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com