Environment-friendly cushioning good-enwrapping performance popcorn-like bridging shoe and making technology thereof

A popcorn and wrapping technology, applied in textile/flexible product manufacturing, shoe soles, shoe uppers, etc., can solve the problems of difficult to achieve good wrapping properties, unsatisfactory environmental protection of shoes, etc., to simplify the upper production process and omit the bottoming process. , the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

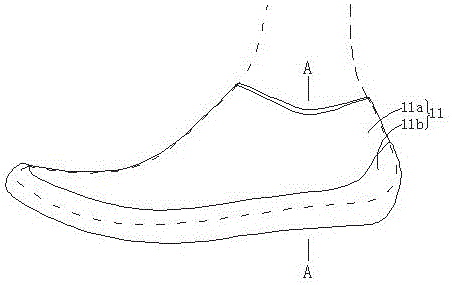

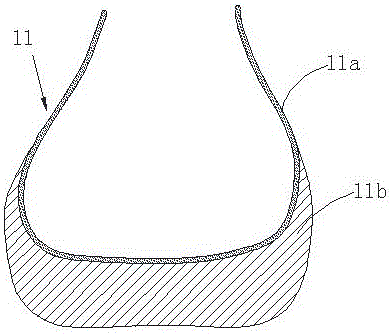

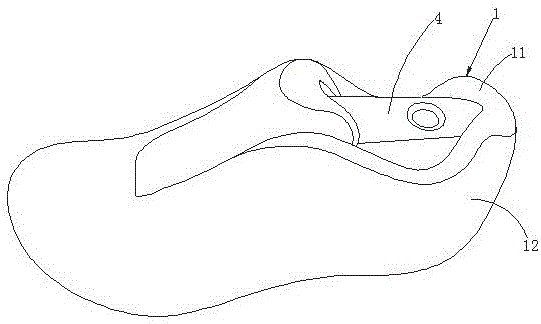

[0037] refer to Figure 4 The popcorn bridge-building shoes with good environment-friendly cushioning and wrapping properties include an upper 1 and a sole 2 , the upper 1 is composed of an inner boot 11 and an upper 12 . refer to figure 1 , figure 2 , The inner boot 11 is composed of an inner lining 11a and an injection molding inner pad 11b. The inner pad 11b is a PU inner pad 11b made of PU material, or a popcorn inner pad 11b made by mixing PU and TPU popcorn particles, and the thickness of the inner pad 11b is 10-20mm. The inner lining 11a is a sock-shaped sock structure, or the inner lining 11a is a structure in which the neckline and bottom of the inner lining of the ordinary shoe upper 1 are open; the inner lining 11a is made of waterproof and / or breathable fabric. The inner lining 11a and the inner pad 11b are connected as one by injection m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com