Full-automatic assembly and riveting machine

A riveting machine, fully automatic technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of increased production costs, increased defect rate, low automation, etc., to achieve stable operation, reduce defective products, and precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described below with reference to the drawings and specific embodiments.

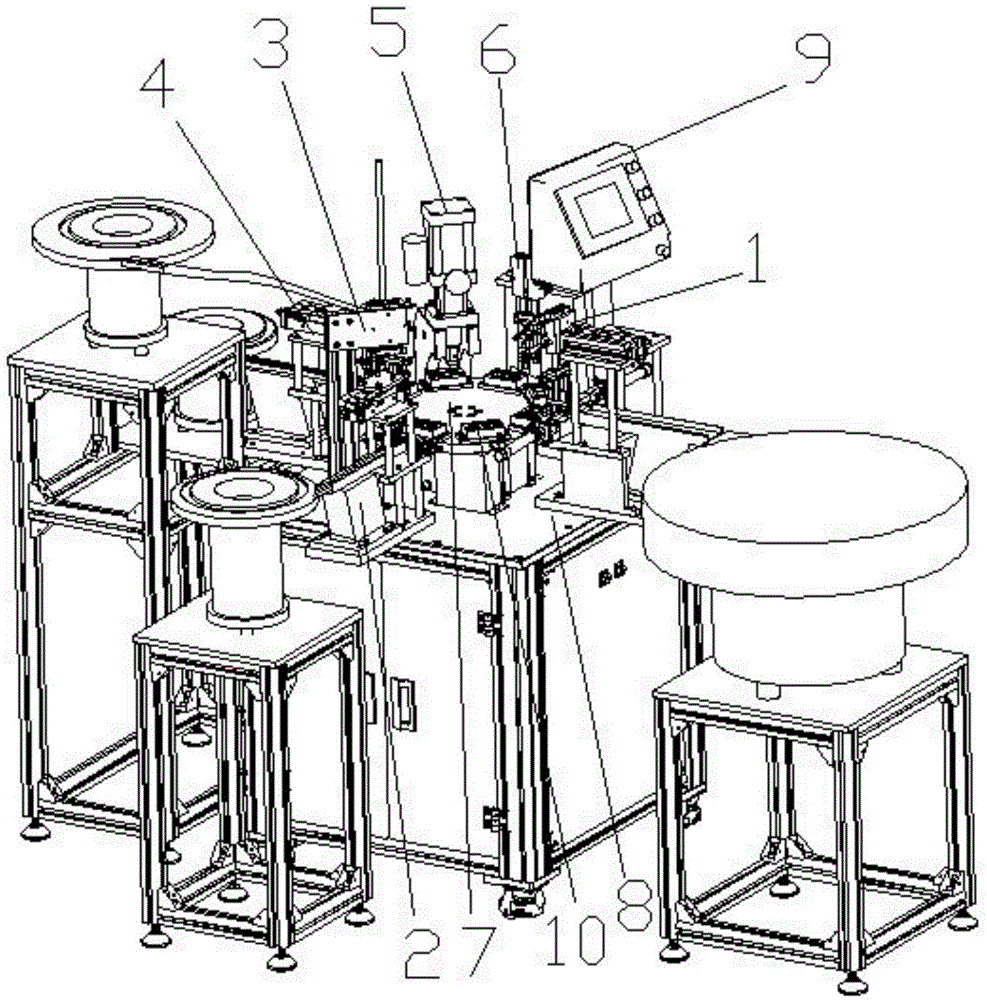

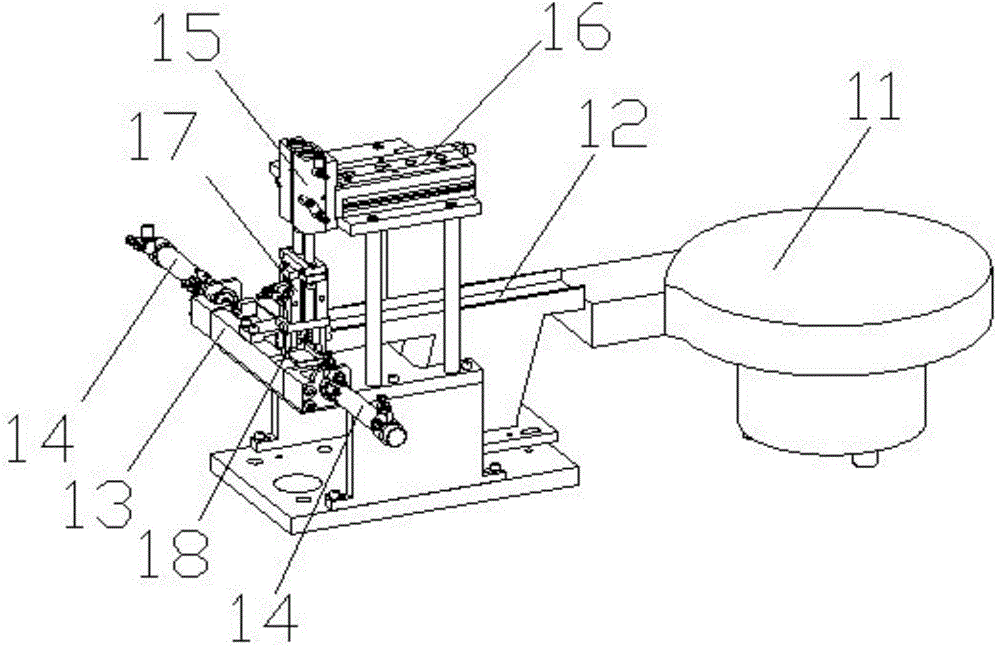

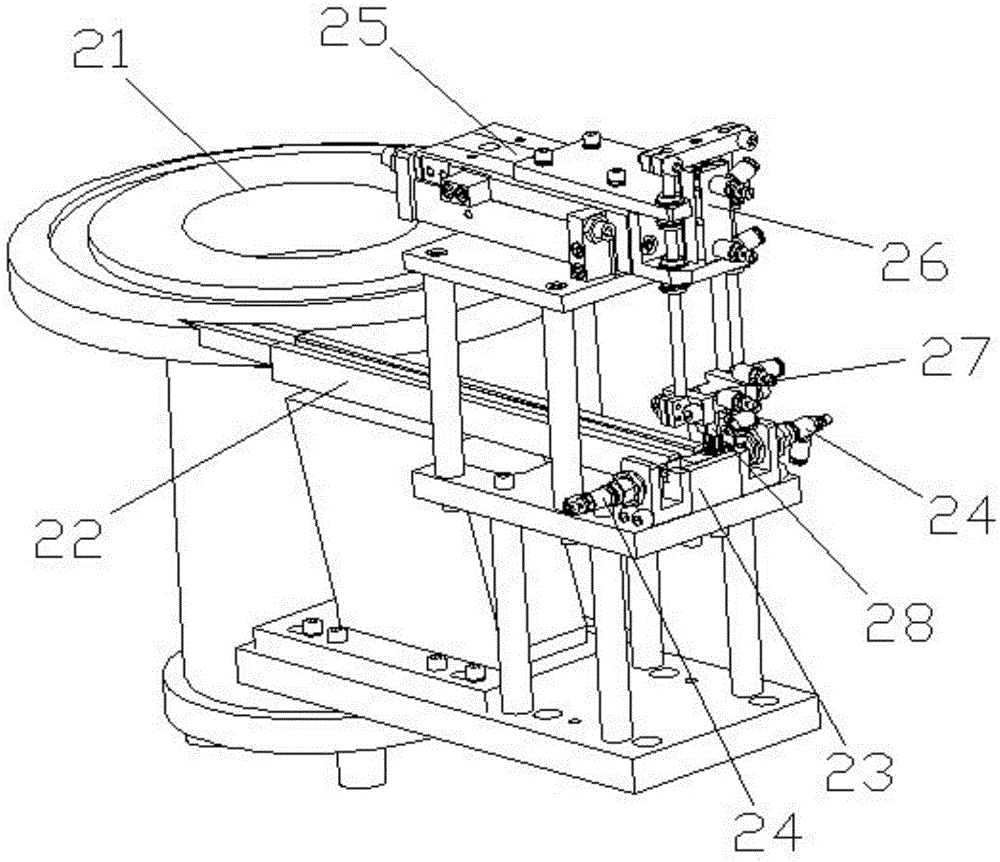

[0023] As attached figure 1 Shown is a fully automatic assembly riveting machine according to the present invention, including main part feeding mechanism 1, aluminum cap feeding mechanism 2, spring feeding mechanism 3, gasket feeding mechanism 4, riveting mechanism 5, and Material mechanism 6, station index plate 7, platen 8, operation screen 9; the center of the platen 8 is provided with a station index plate 7, and the periphery of the station index plate is sequentially arranged as a main part feeding mechanism 1. Aluminum cap feeding mechanism 2. Spring feeding mechanism 3, gasket feeding mechanism 3, riveting mechanism 5, reclaiming mechanism 6, operating panel 9, each of the mechanism components is electrically connected to the operating panel 9, through The operation screen can complete the automatic or manual control of the machine; the station index plate 7 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com