Green bamboo skin removal machine

A green machine and bamboo technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of poor adaptability of greening equipment, easy to mistakenly remove bamboo meat and greening, and poor processing effect of greening, saving equipment cost investment, Good de-greening effect and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

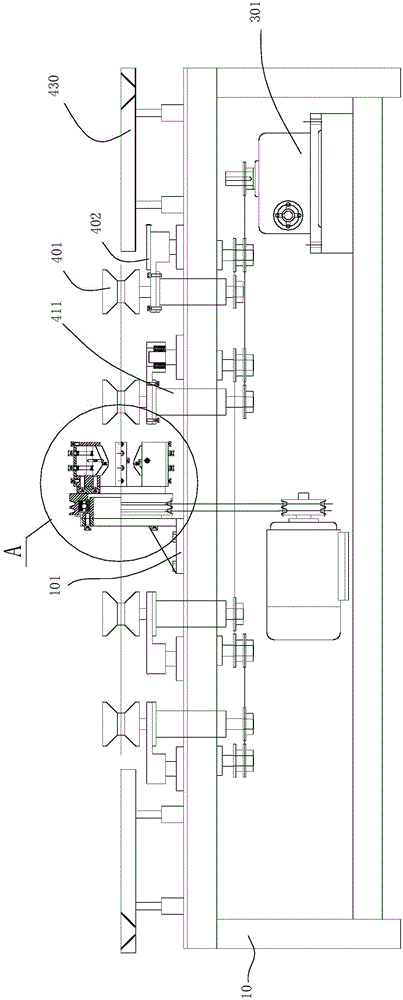

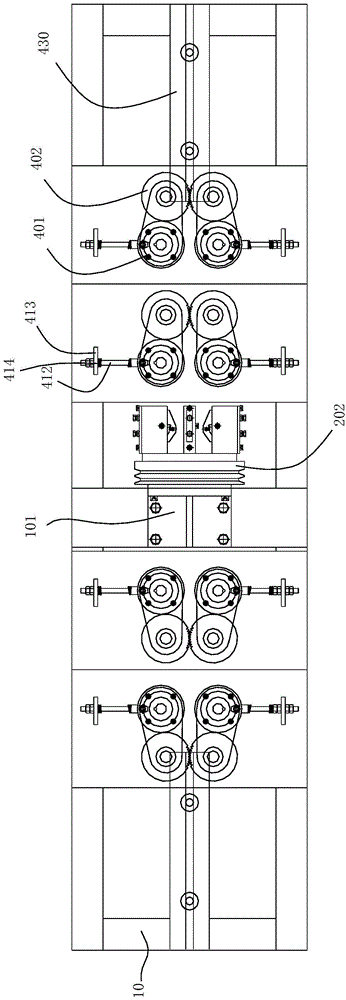

[0023] Example: such as figure 1 , figure 2 , image 3 with Figure 4 The shown bamboo degreening machine, the bamboo degreening machine consists of frame 10, a degreening tool assembly for planing bamboo green, four groups driven by motor 301 for pushing bamboo along its length direction. The pushing mechanism of green cutter assembly and two V-shaped grooves 430 for supporting the circular bamboo tube form. Wherein, four groups of pushing mechanisms are fixed on the frame 10 and evenly distributed on both sides of the de-greening cutter assembly, and the position of the pushing mechanism is corresponding to the de-greening cutter assembly; two V-shaped grooves 430 are respectively positioned at the outside of the pushing mechanism, and corresponding to the position. specifically:

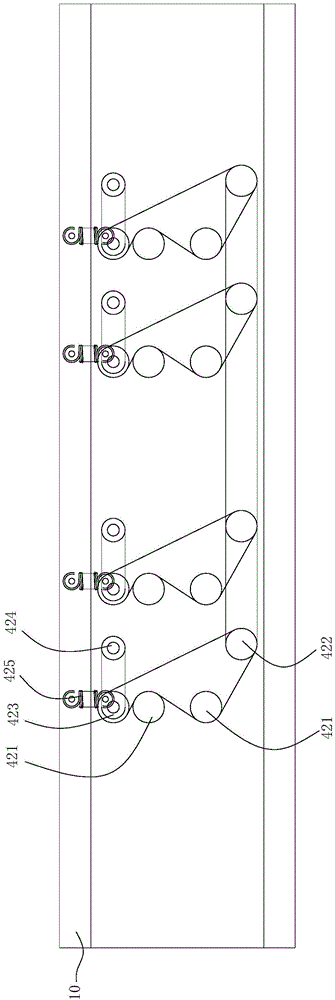

[0024] Each group of above-mentioned pushing mechanisms includes a pair of elastic clamping mechanisms installed on the frame 10, two rollers 401, a transmission mechanism and two synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com