Fiber-reinforced resin structure

A fiber-reinforced resin and structure technology, applied in thin material processing, vehicle seats, movable seats, etc., to achieve the effect of high mechanical properties and high-efficiency absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below.

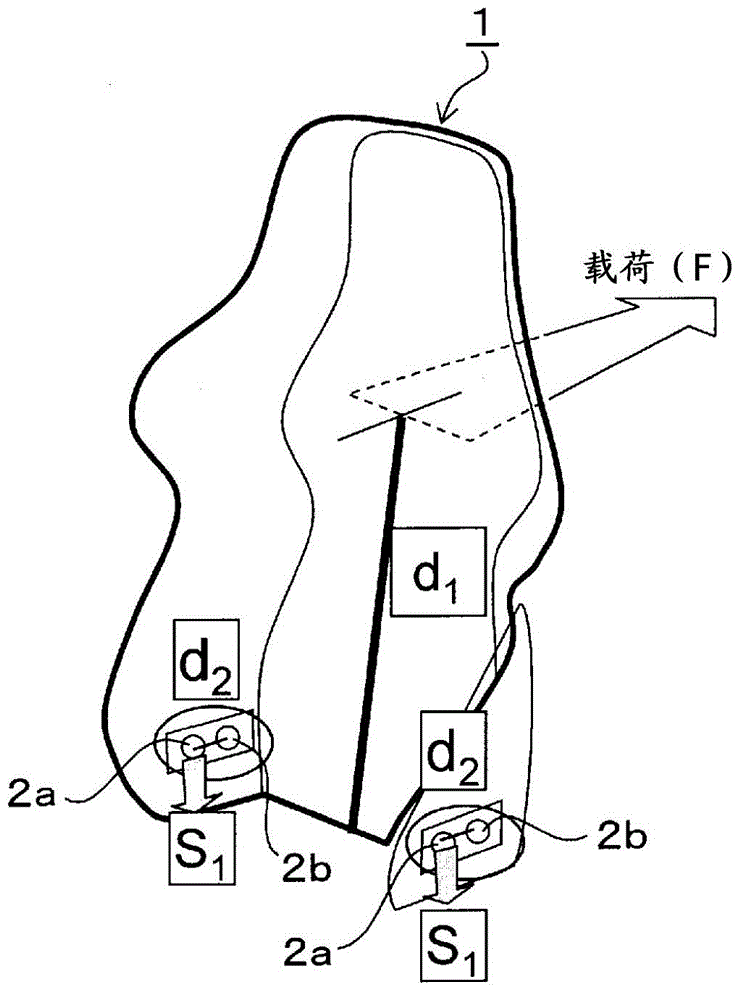

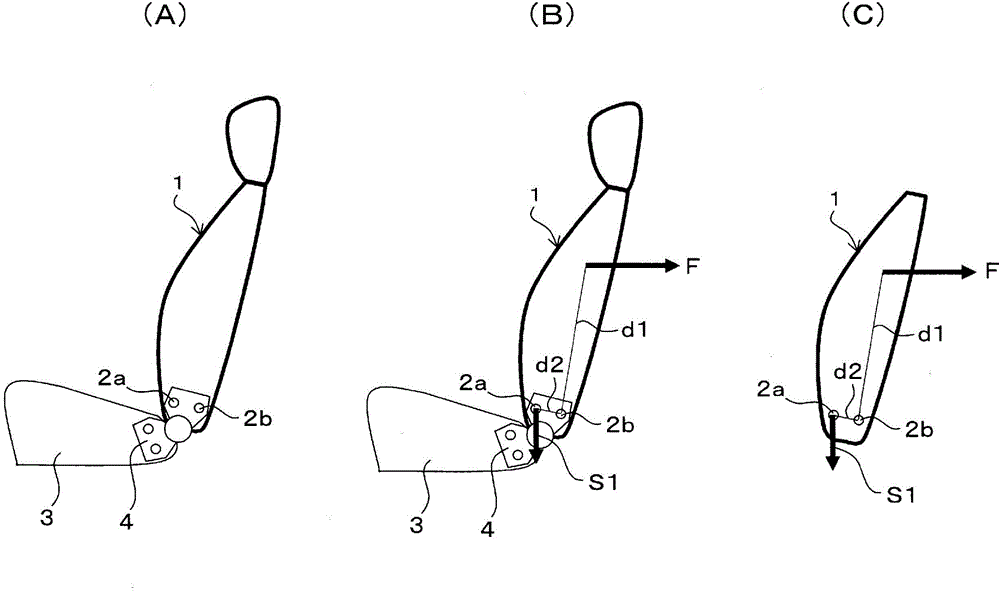

[0032] figure 1 , figure 2 An embodiment of the present invention is shown, particularly a case where the fiber-reinforced resin structure of the present invention is configured as a frame structure for a seat back of a vehicle seat. exist figure 1 , figure 2 In the figure, reference numeral 1 denotes a frame structure for a seat back of a vehicle seat as an example of the fiber-reinforced resin structure of the present invention. The seat back frame structure 1 is constituted as an integral molded body of a fiber-reinforced resin structure using carbon fibers as reinforcing fibers. On both sides of the lower part of the frame structure 1 for the seat back, there are respectively provided in the approximately horizontal direction a connecting member (for example, a bolt) for connecting to other members, such as the rotation adjustment member 4 constituting a part of the seat frame 3 , to be inserted. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com