Preparation method of SBA-16/MOR composite molecular sieve, catalyst and application in double branched chain isomerization

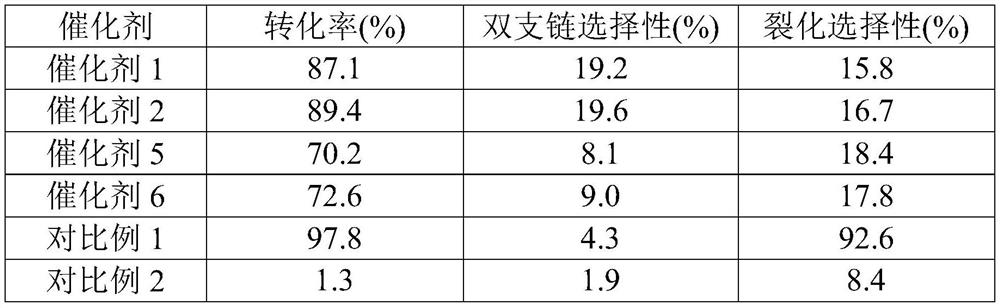

A technology of SBA-16 and composite molecular sieve, which is applied in the field of petroleum processing, and can solve the problems of small specific surface area, cracking, and low selectivity of double-branched isoparaffins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

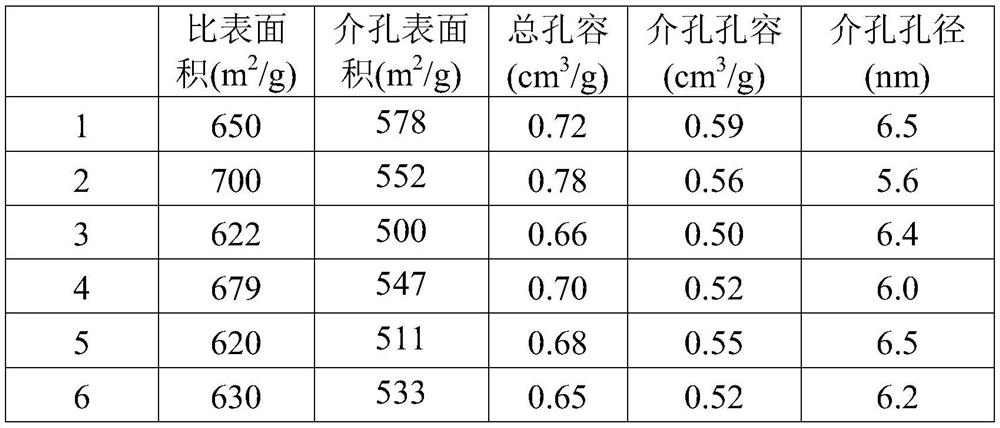

Examples

Embodiment 1

[0085] Preparation of MOR nanocrystal precursor solution: Weigh 8g of activated diatomite, 1.8g of activated retort earth, and 4g of NaOH, 0.2g of seed crystal, dissolve in 60g of deionized water, and then age in a water bath at 80°C for 4h. The mixture was put into a stainless steel crystallization kettle lined with polytetrafluoroethylene, and the temperature was raised to 170° C. for static crystallization for 20 h. Cool to room temperature after crystallization, stir evenly and set aside.

[0086] Pre-hydrolysis of silicon-aluminum source: Add 5 g of the above-mentioned nanocrystalline precursor solution and 5 g of tetraethyl orthosilicate to 18 g of hydrochloric acid solution, adjust the pH value of the solution to 2, perform pre-hydrolysis at 60° C. for 5 h, and then let stand for 4 h.

[0087] Composite molecular sieve preparation: Slowly add the pre-hydrolysis solution to the template agent F127 solution (0.15g F127 dissolved in 42g 0.5M hydrochloric acid solution), 0....

Embodiment 2

[0091] This example provides a SBA-16 / MOR composite molecular sieve carrier material, the preparation steps are the same as in Example 1, only some parameters are adjusted, as follows:

[0092] Preparation of MOR nanocrystal precursor solution: Weigh 6.5g of activated diatomite, 4g of 600°C activated bauxite, and 7g of NaOH, dissolve 0.1g of seed crystal in 60g of deionized water, and then age in a water bath at 80°C for 4h. The mixture was put into a stainless steel crystallization kettle lined with polytetrafluoroethylene, heated to 170°C for static crystallization for 20 h. After the crystallization is completed, cool to room temperature, stir evenly and set aside.

[0093] Pre-hydrolysis of the silicon-aluminum source of the composite material: Add 5 g of the above-mentioned nanocrystalline precursor solution and 5 g of methyl orthosilicate to 20 g of hydrochloric acid solution, then adjust the pH value of the solution to 4, perform pre-hydrolysis at 60 ° C for 5 hours, an...

Embodiment 3

[0098] This example provides a SBA-16 / MOR composite molecular sieve carrier material, the preparation steps are the same as in Example 1, only some parameters are adjusted, as follows:

[0099] Preparation of MOR nanocrystal precursor solution: Weigh 7.2g of activated diatomite, 1.5g of bauxite activated at 600°C, 2.4g of rectorite, and 6g of NaOH, and dissolve 0.1g of seed crystal in 60g of deionized water. After aging in a water bath at 80°C for 4h, the mixture was put into a stainless steel crystallization kettle lined with polytetrafluoroethylene, and heated to 170°C for static crystallization for 24h. Cool to room temperature after crystallization, stir evenly and set aside.

[0100] Pre-hydrolysis of silicon-aluminum source of composite materials: Add 5 g of the above-mentioned nanocrystalline precursor solution and 4 g of methyl orthosilicate to 20 g of nitric acid solution, then adjust the pH value of the solution to 6, perform pre-hydrolysis at 60 ° C for 5 hours, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com