Double-pole positioning mechanism for liquid crystal display screen in exhibition

A technology of liquid crystal display and positioning mechanism, applied in the direction of supporting machines, mechanical equipment, machine/stands, etc., can solve the problem of inability to flexibly adjust the installation height and front and rear elevation angles of the liquid crystal display, cumbersome installation of the liquid crystal display, time-consuming and laborious, etc. problems, to achieve the effect of simple structure, convenient positioning, and improved layout efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

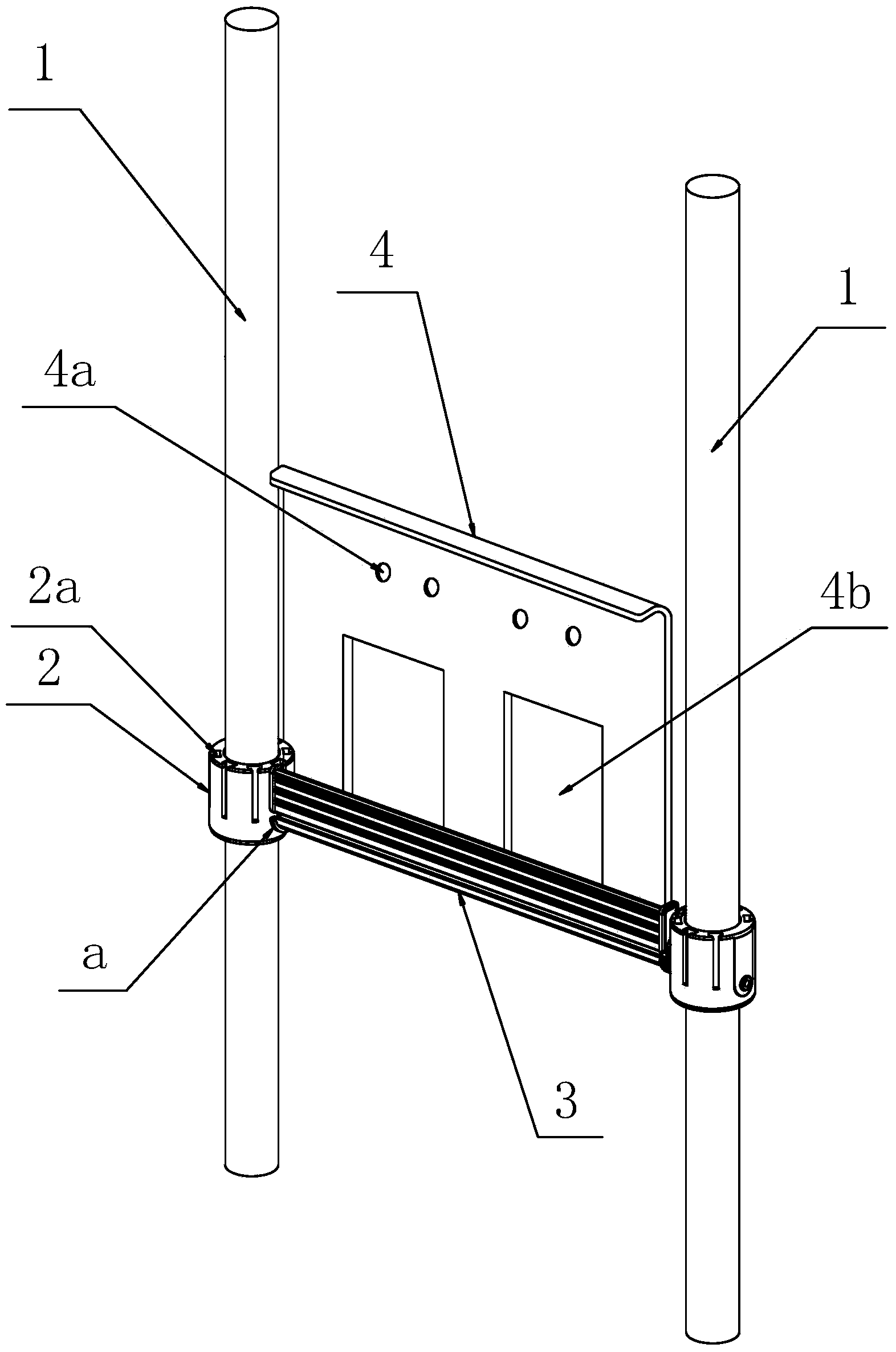

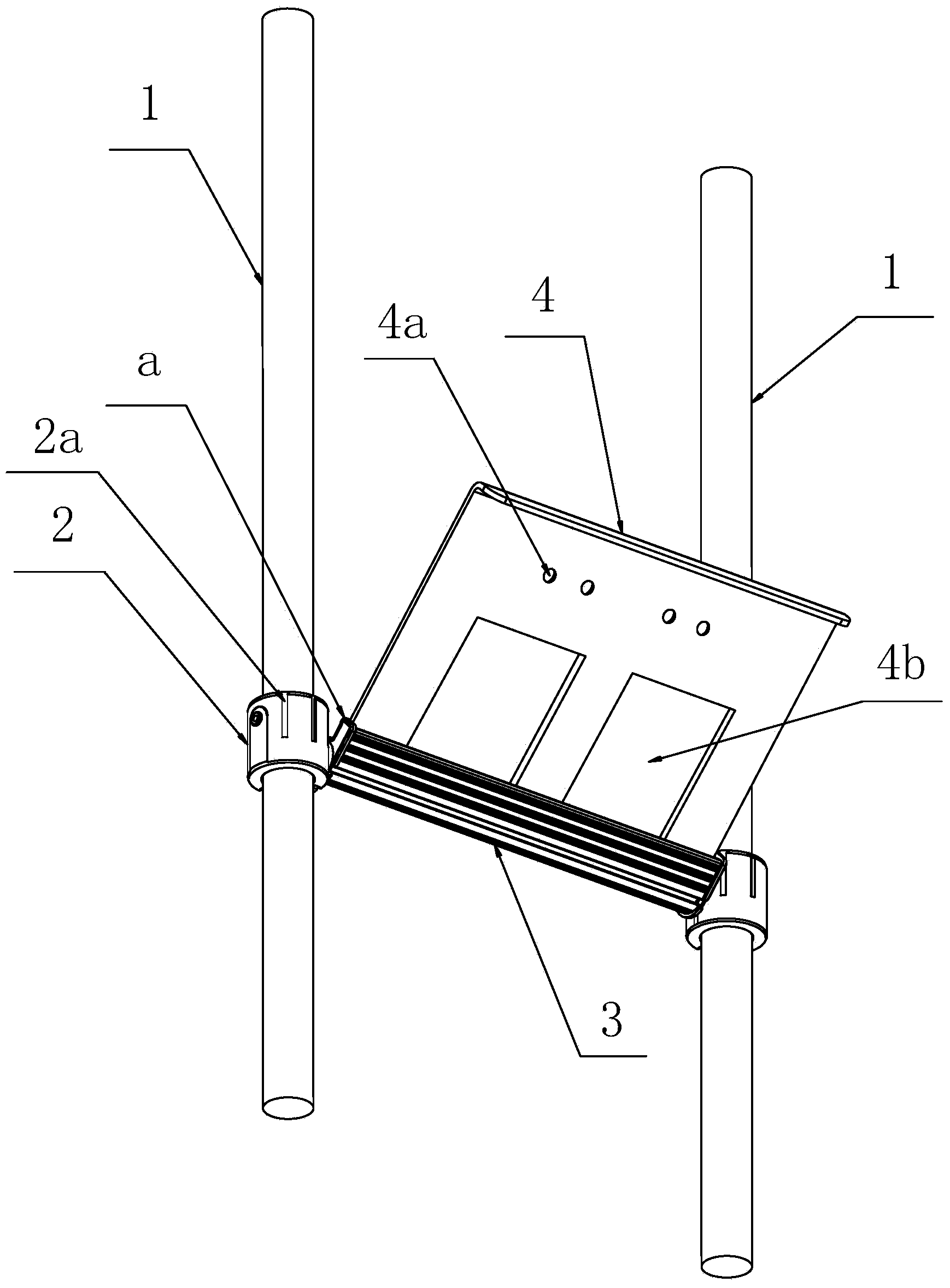

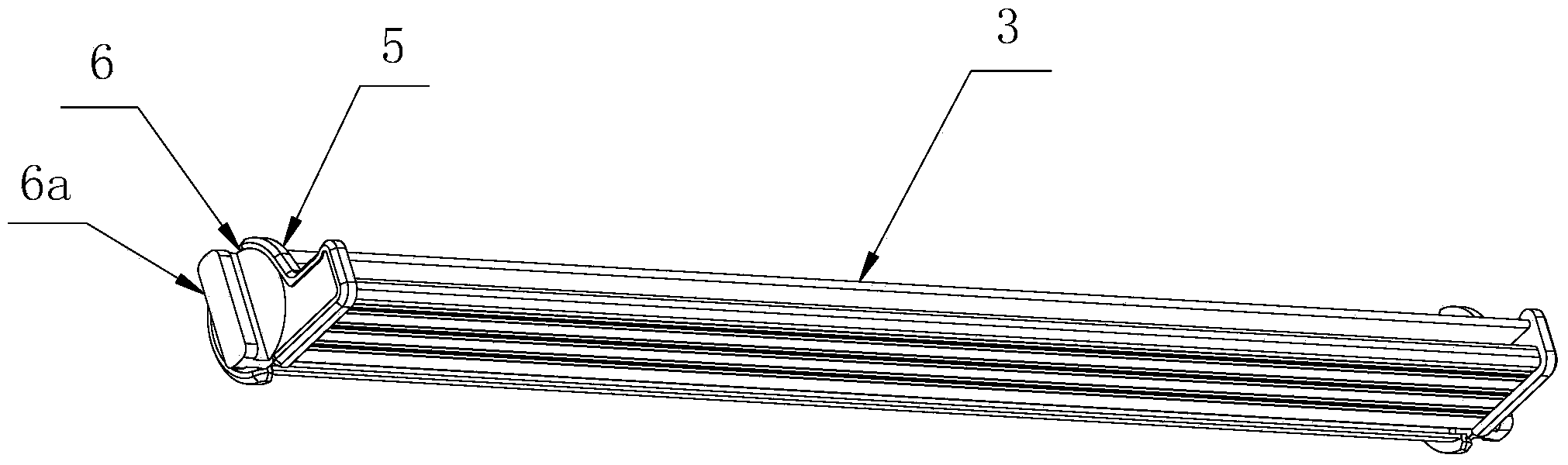

[0025] Example: Combining Figure 1 ~ Figure 5 As shown, it is a specific implementation of the dual-bar positioning mechanism of the LCD display in the exhibition of the present invention. First as figure 1 with figure 2 As shown, the mechanism has two metal uprights 1 arranged in parallel, and the bottom of each metal upright 1 is fixed with a base (not shown in the figure). A sleeve joint 2 is sleeved on the two metal vertical rods 1 at the same height, and each sleeve joint 2 is fixed to the metal stand by suction and fixation by a plurality of magnetic blocks (not visible in the figure) arranged on the inner wall of the sleeve joint 2. On pole 1. A supporting base bar 3 is arranged between the two sleeve joints 2, and both ends of the supporting base bar 3 are rotatably connected to the corresponding sleeve joint 2 through a ratchet self-locking rotating mechanism a, while supporting the base bar 3 A liquid crystal display assembly board 4 is fixed. In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com