A method and construction method for cementing plugs in horizontal wells

A construction method and technology for horizontal wells, applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as injection of cement plugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings, not to limit the protection scope of the present invention, and all improvements obtained by using the design idea of the present invention belong to the protection scope of the present invention.

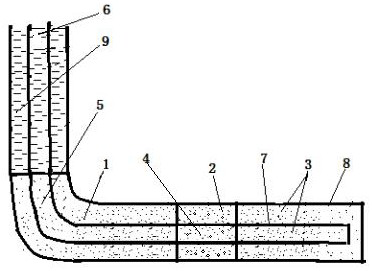

[0017] see figure 1 , a method for cementing plugs in horizontal wells, is: make the densities of the cement slurry and the spacer fluid equal, and make the space between the cement slurry and the spacer fluid of equal density replaced from the construction pipe string into the annulus between the construction pipe string and the casing , and make the interfaces at both ends of the cement slurry and spacer fluid replacement section in the annulus between the construction pipe string and the casing flush with the interface at both ends of the cement slurry and spacer fluid replacement section in the construction pipe string, and The bottom of the construction string, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com