Device and method for measuring flow rate in ramjet combustor film cooling jacket

A ramjet, air film cooling technology, applied in the cooling of engines, ramjet engines, engine components, etc., can solve the problems of large size, unable to achieve the flow field measurement of cooling jackets with a structural size of about 10mm or even smaller, etc. Achieve the effect of improving measurement accuracy, facilitating judgment, and reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

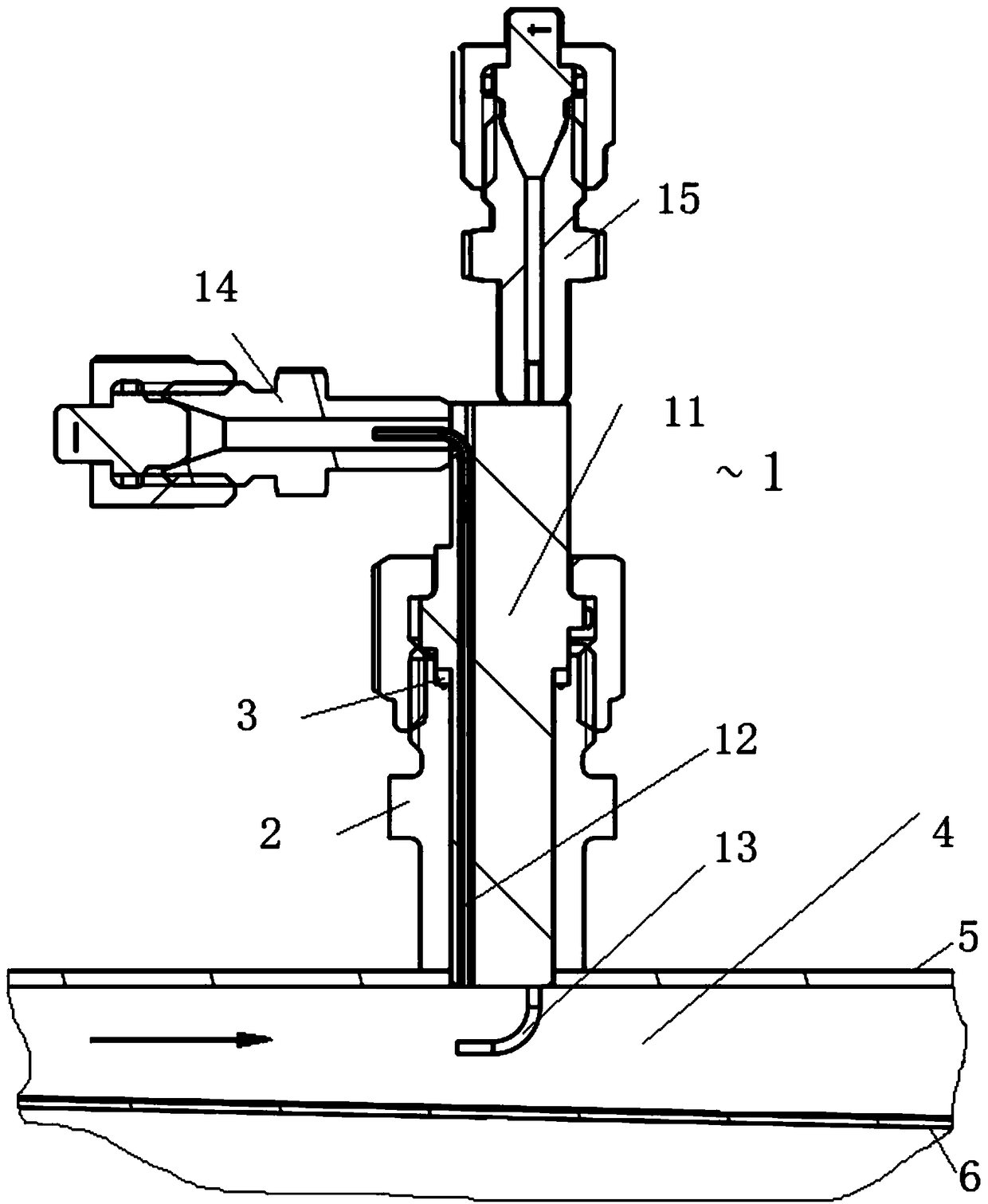

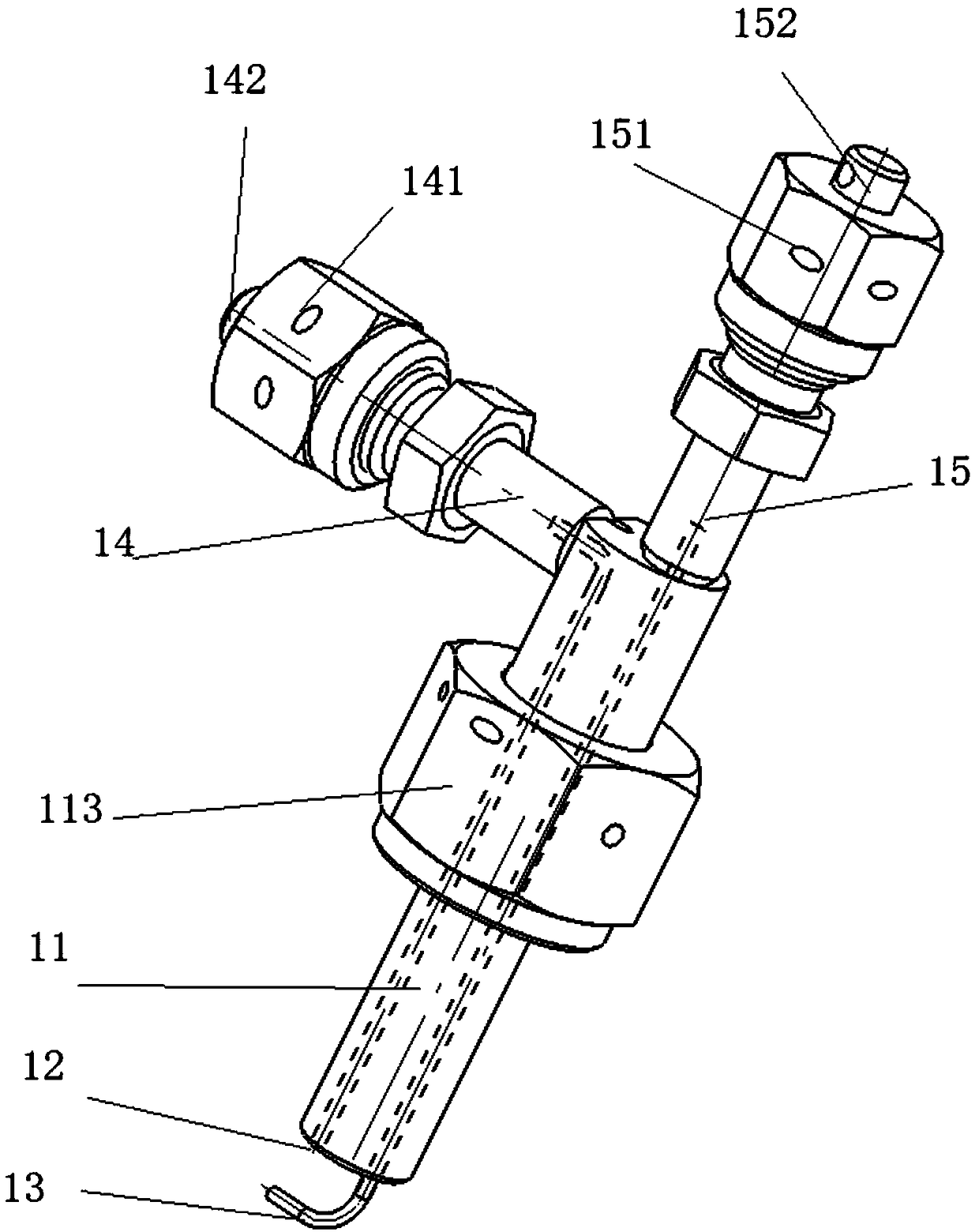

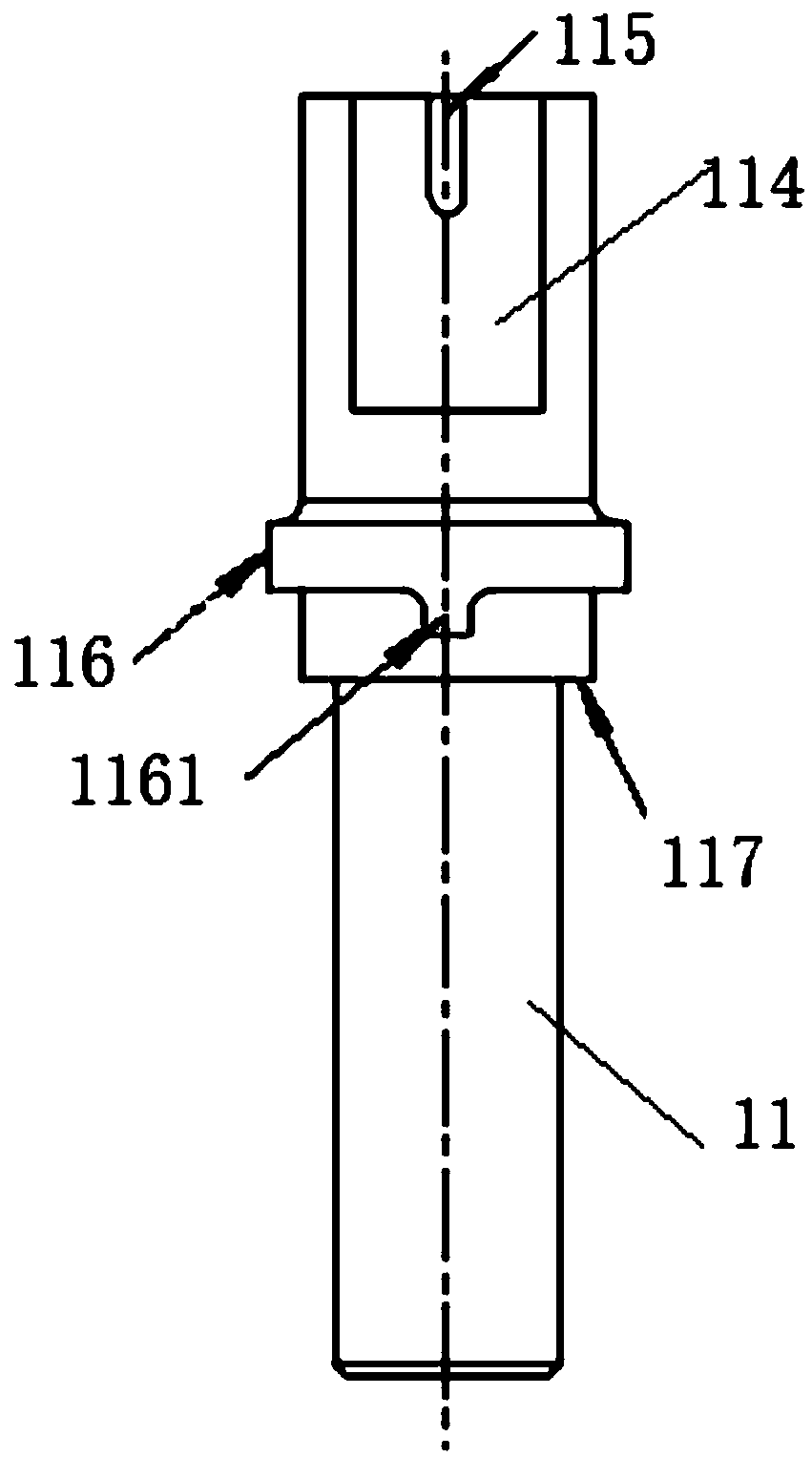

[0052] like figure 1 , figure 2 As shown, this embodiment provides a device for measuring the flow velocity in the film cooling jacket of the combustion chamber of a ramjet engine, including a measuring rake 1 and a nozzle 2 for the combustion chamber. The measurement rake 1 includes a columnar rake core 11 , a static pressure guide tube 12 , a total pressure guide tube 13 , a static pressure connection nozzle 14 and a total pressure connection nozzle 15 . Both the static pressure guide tube 12 and the total pressure guide tube 13 are capillary tubes of Φ1.2×0.15 mm. Both the static pressure connection nozzle 14 and the total pressure connection nozzle 15 are provided with plugs 141 , 151 , and the plugs are fastened by nuts 142 , 152 . The rake core is made of GH3536 alloy, and the total pressure guide tube and static pressure guide tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com