Traction wheel with small wrap angle and large friction

A technology of traction sheave and wrapping angle, which is applied to components with teeth, belts/chains/gears, portable lifting devices, etc. It can solve the problems of wire rope shedding, large wear, and large friction, so as to improve traction, Less wear and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

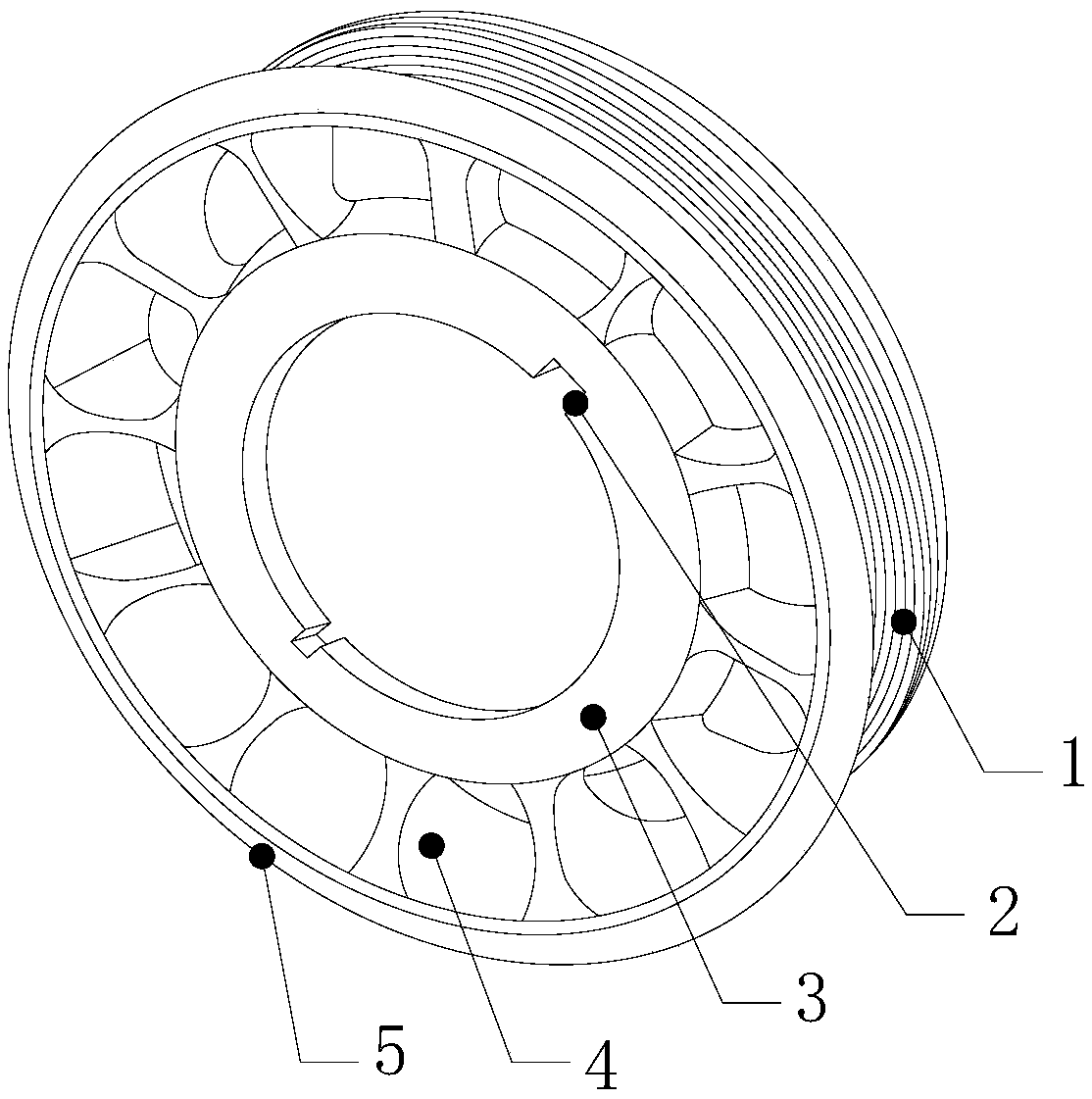

[0023] see Figure 1-Figure 5 , the present invention provides a traction sheave with small wrapping angle and high friction, its structure includes rope groove 1, bayonet 2, inner steel ring 3, steel column 4, outer steel ring 5, the inner diameter of the outer steel ring 5 is larger than The outer diameter of the inner steel ring 3, the outer steel ring 5 and the inner steel ring 3 are connected and fixed together by more than two steel columns 4, and the inner steel ring 3 is provided with two centrosymmetric bayonets 2 , the bayonet 2 and the inner steel ring 3 are mold-integrated structures, and the outer steel ring 5 avoids having more than two rope grooves 1 outside.

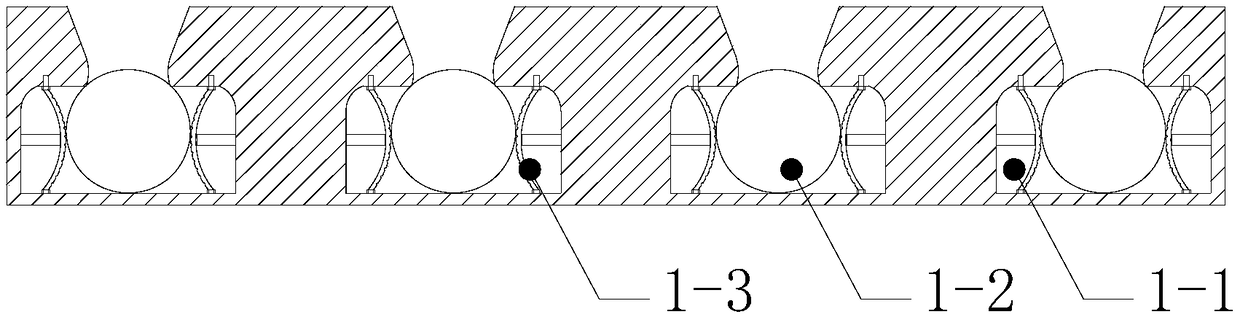

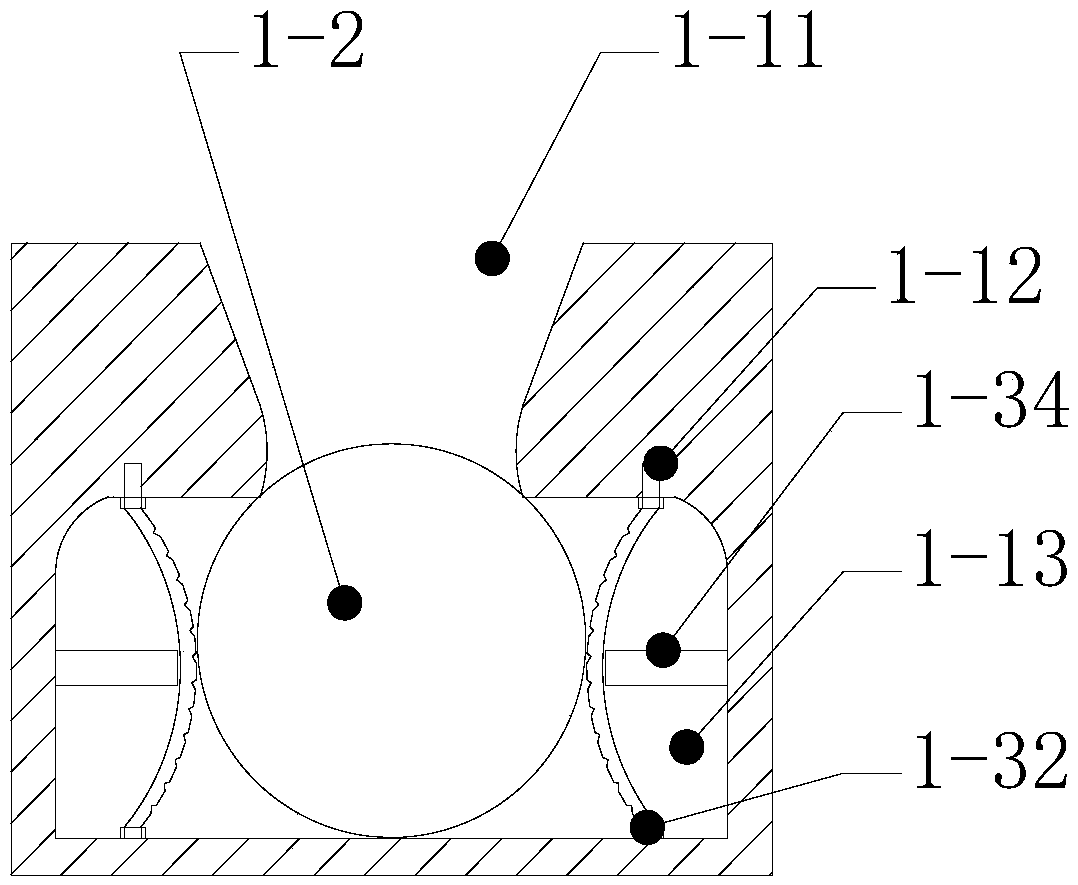

[0024] The rope groove 1 is mainly composed of a groove structure 1-1, a steel wire rope 1-2, and a natural elastic clamping mechanism 1-3. The inner bottom of the groove structure 1-1 is provided with a natural elastic clamping mechanism 1- 3. The steel wire rope 1-2 is located between the two natural e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com