Incremental hot air countercurrent drying device and method

A drying device and drying method technology, applied in the direction of progressive dryer, drying gas arrangement, tobacco drying, etc., can solve the problems of poor dehydration ability of the device, affect the processing quality of tobacco sheets, and poor drying efficiency, and shorten the drying time , Improve the moisture absorption capacity and improve the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

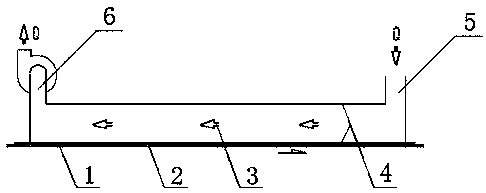

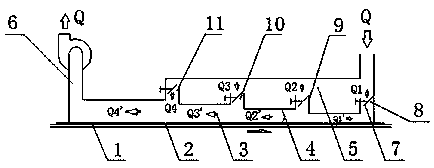

[0024] Such as image 3 As shown, the incremental hot air countercurrent drying device for drying tobacco flakes in this embodiment includes a conveyor belt 1, an existing heating device is evenly arranged below the conveyor belt 1, and a ventilation tunnel 4 is arranged above the conveyor belt 1, and the ventilation tunnel 4 is provided with 4 vents, and the air supply duct 5 communicates with the 4 vents, and hot air enters the ventilation tunnel 4 from each vent. The four ventilation openings are arranged in steps, the first ventilation opening 8 is arranged close to the air supply duct 5, and is closest to the conveyor belt 1, the second ventilation opening 9, the third ventilation opening 10 and the fourth ventilation opening 11 are connected to the conveyor belt 1. As the distance increases gradually, the cross-sectional area of the ventilation tunnel increases gradually along the wind direction.

[0025] The other end of the ventilation tunnel 4 is provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com