Loop type heat pipe

A loop pipe and heat pipe technology, applied in the field of loop type heat pipes, can solve the problems of unable to assist heat dissipation, overheating of loop type heat pipes, and difficult to control the direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

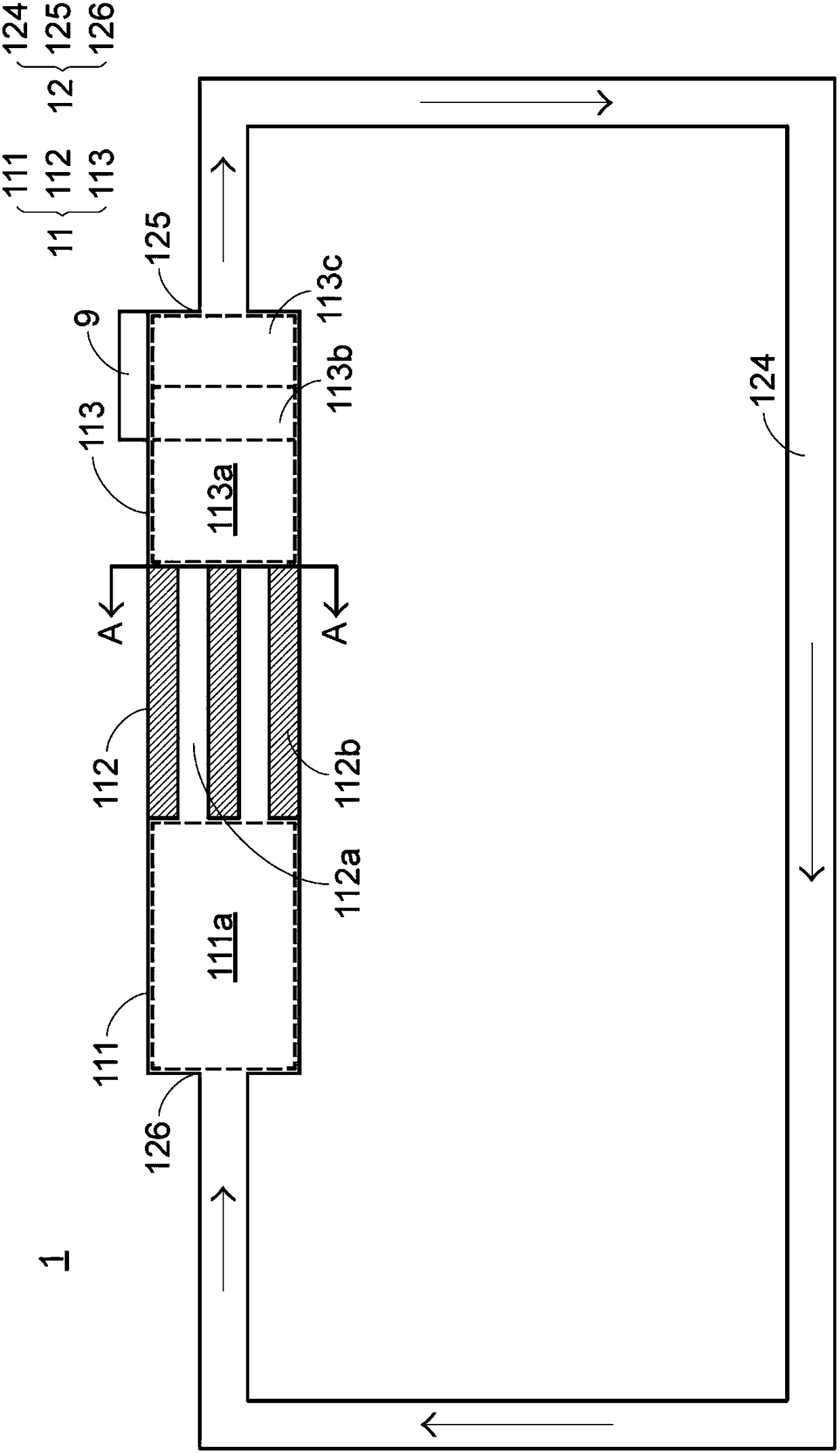

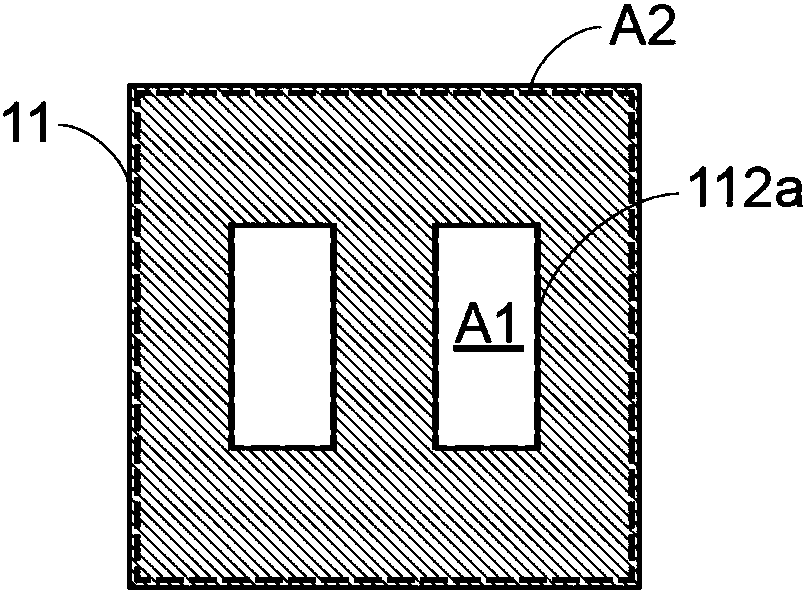

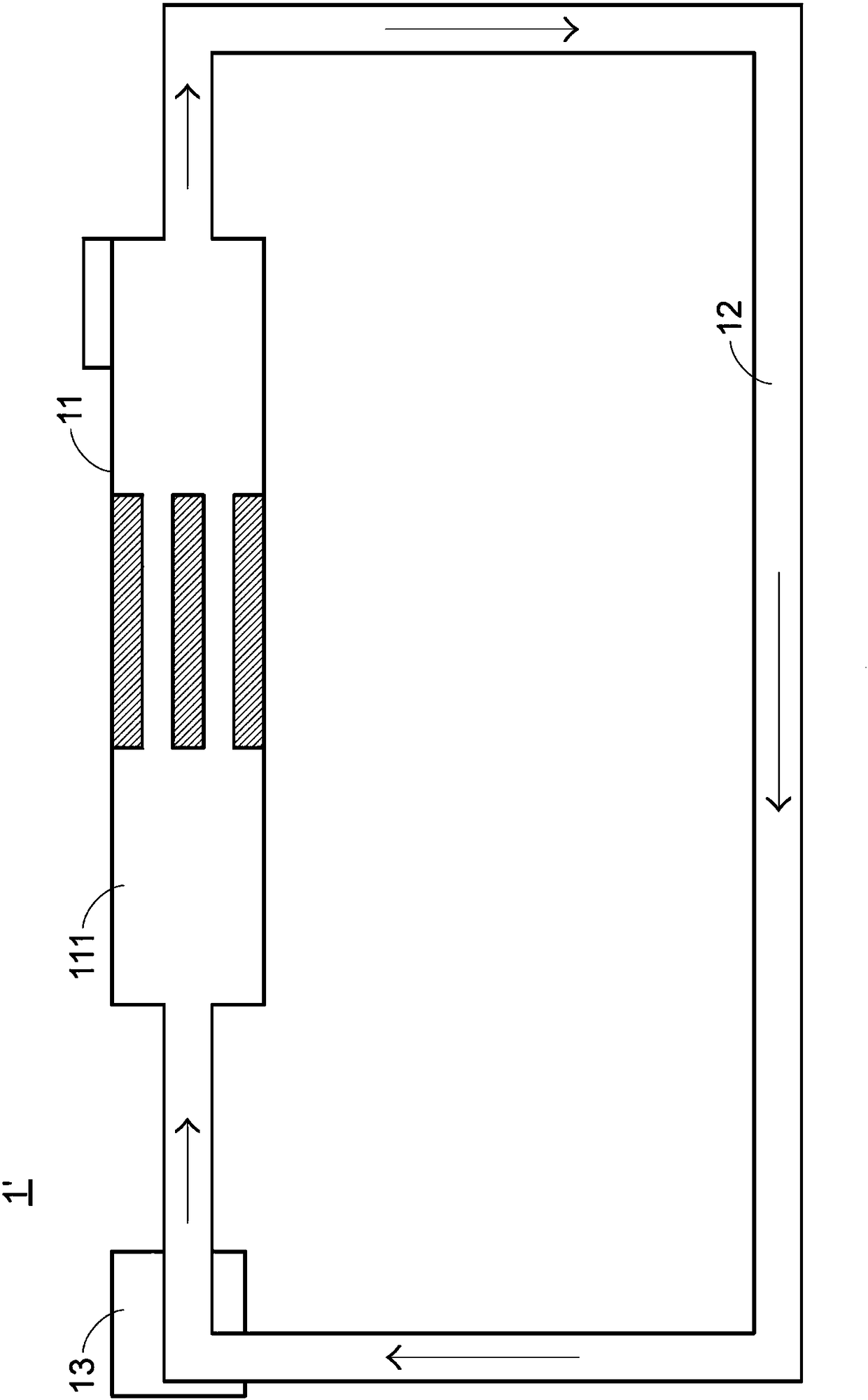

[0019] Please see first figure 1 , figure 1 It is a schematic top view of the first embodiment of the loop heat pipe of the present invention. The loop-type heat pipe 1 of the present invention can be configured in most electronic equipments to reduce the operating temperature of the electronic components (hereinafter referred to as a heat source 9 ) of the electronic equipments. Preferably, the loop-type heat pipe 1 is attached to the heat source 9 to absorb part of the heat from the heat source 9 . The loop-type heat pipe 1 of the present invention includes an evaporation cavity 11 and a loop tube body 12. The loop tube body 12 has a tube body 124, an inlet nozzle 125 and an outlet nozzle 126, and the loop tube body 12 is connected to the evaporation cavity body 11. , wherein an outlet of the evaporation chamber 11 is connected to the inflow nozzle 125 of the return pipe 12 , and an inlet of the evaporation chamber 11 is connected to the outlet 126 of the return pipe 12 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com