High-rigidity transverse folding airfoil

A foldable, high-rigidity technology, applied in the launcher and other directions, can solve the problems of affecting aerodynamic performance, large locking mechanism, thick airfoil, etc., and achieve the effect of less space occupation, reduced airfoil rigidity, and good rigidity characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

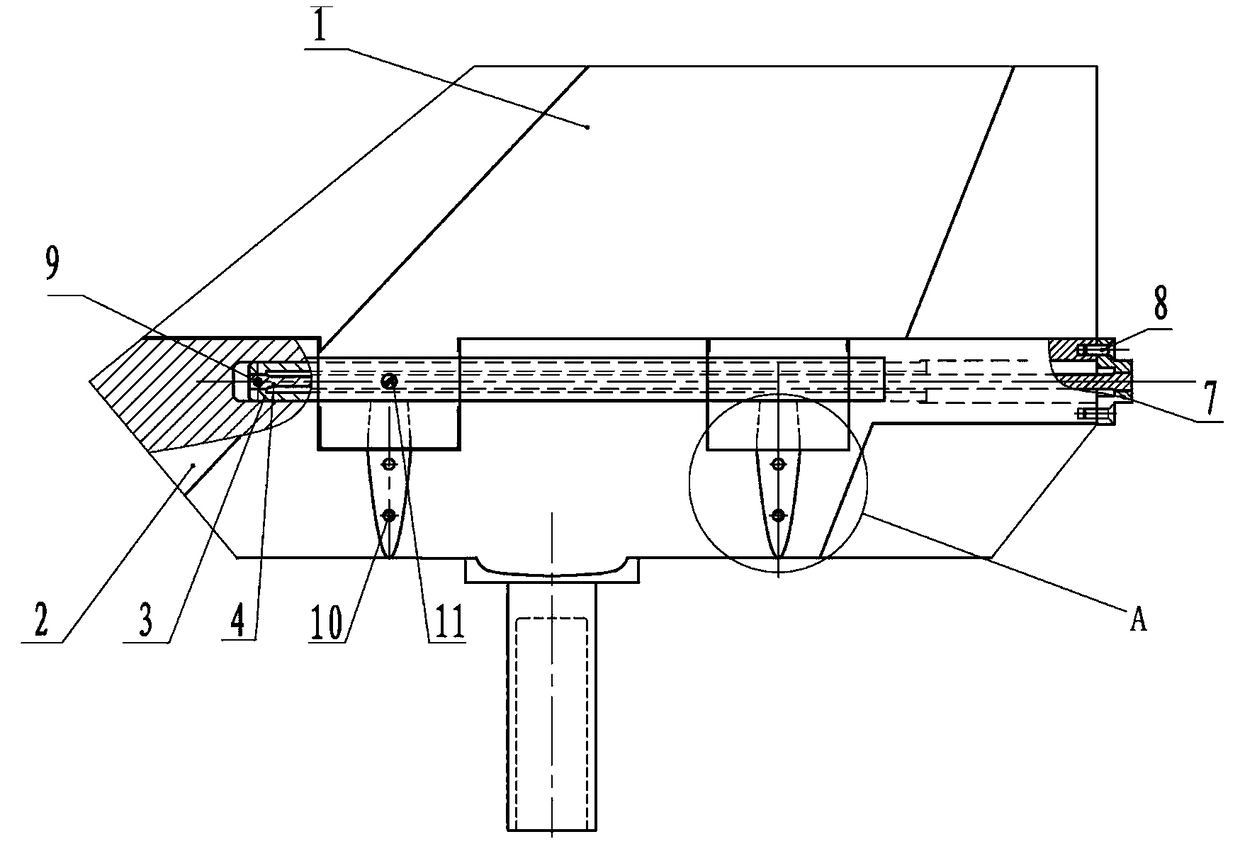

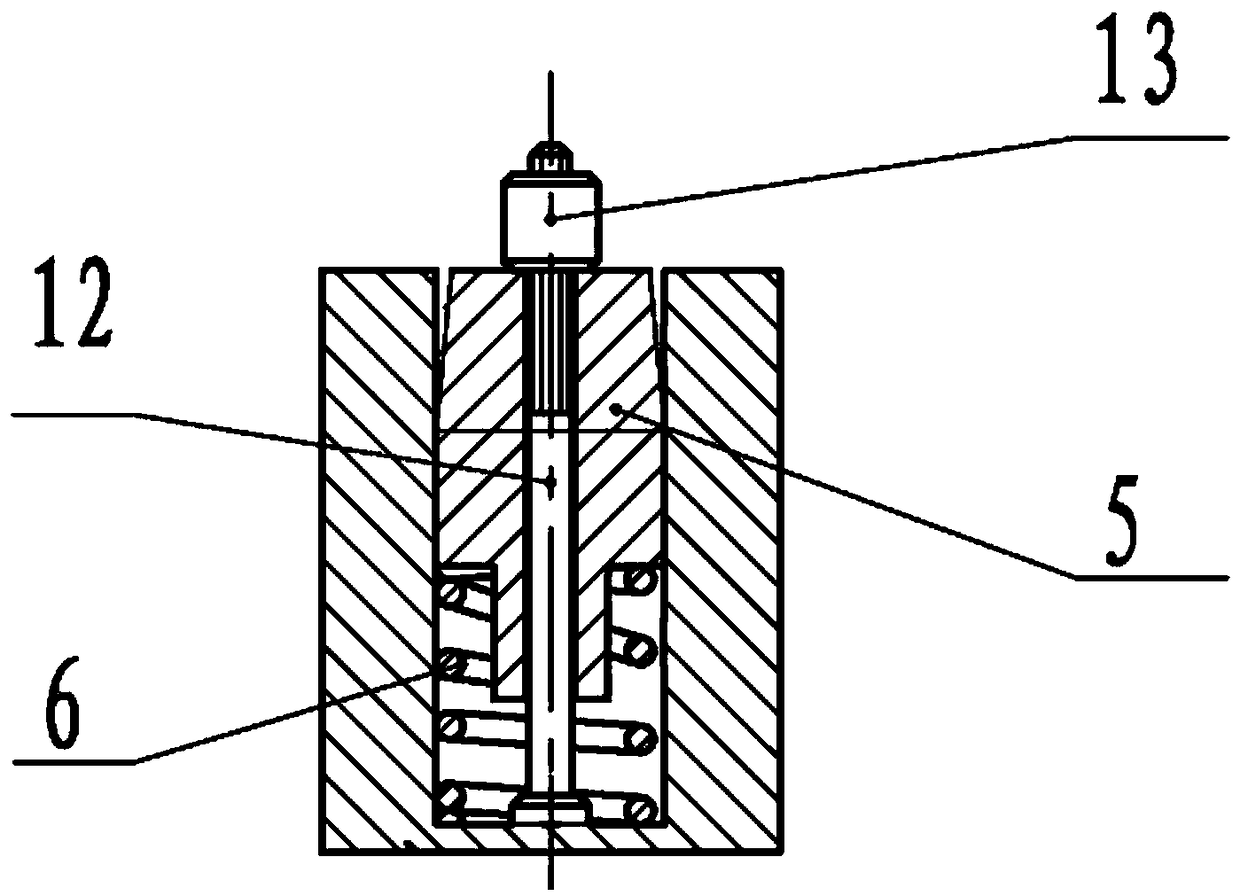

[0033] Embodiment: the outer wing 1 is provided with two rectangular sawtooths, the inner wing 2 is provided with two U-shaped grooves, and the middle part is provided with a cylindrical through hole, and the rotating shaft 3 is installed in the through hole to connect the outer wing 1 with the inner wing 2; the outer wing 1 A tapered hole is provided in the rectangular sawtooth to cooperate with the locking pin 5 to lock the outer wings.

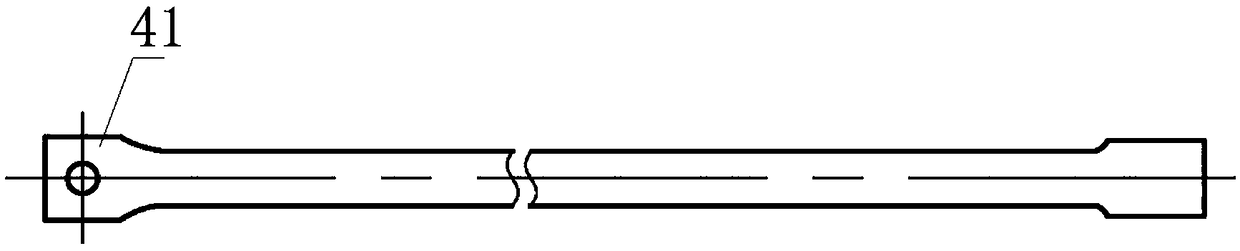

[0034] The unfolding mechanism of the outer wing 1 includes a rotating shaft 3, a torsion bar 4 with certain elasticity, a rear cover 7, screws I8, screws II9, and screws IV11. The rotating shaft 3 passes through the coaxial holes on the inner wing 2 and the outer wing 1 to connect them, and is fixed on the outer wing 1 with screws IV11 to prevent its relative rotation and left-right sliding; the torsion bar 4 is inserted into the corresponding hole at the end of the outer wing 1 At the mouth position, one end of the torsion bar 4 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com