Three-dimensional angularity detection system and detection method

A detection system, angular technology, applied in the analysis of materials, instruments, etc., can solve the problem of inaccurately characterizing the overall angularity of particles, and achieve the effect of improving the accuracy of characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

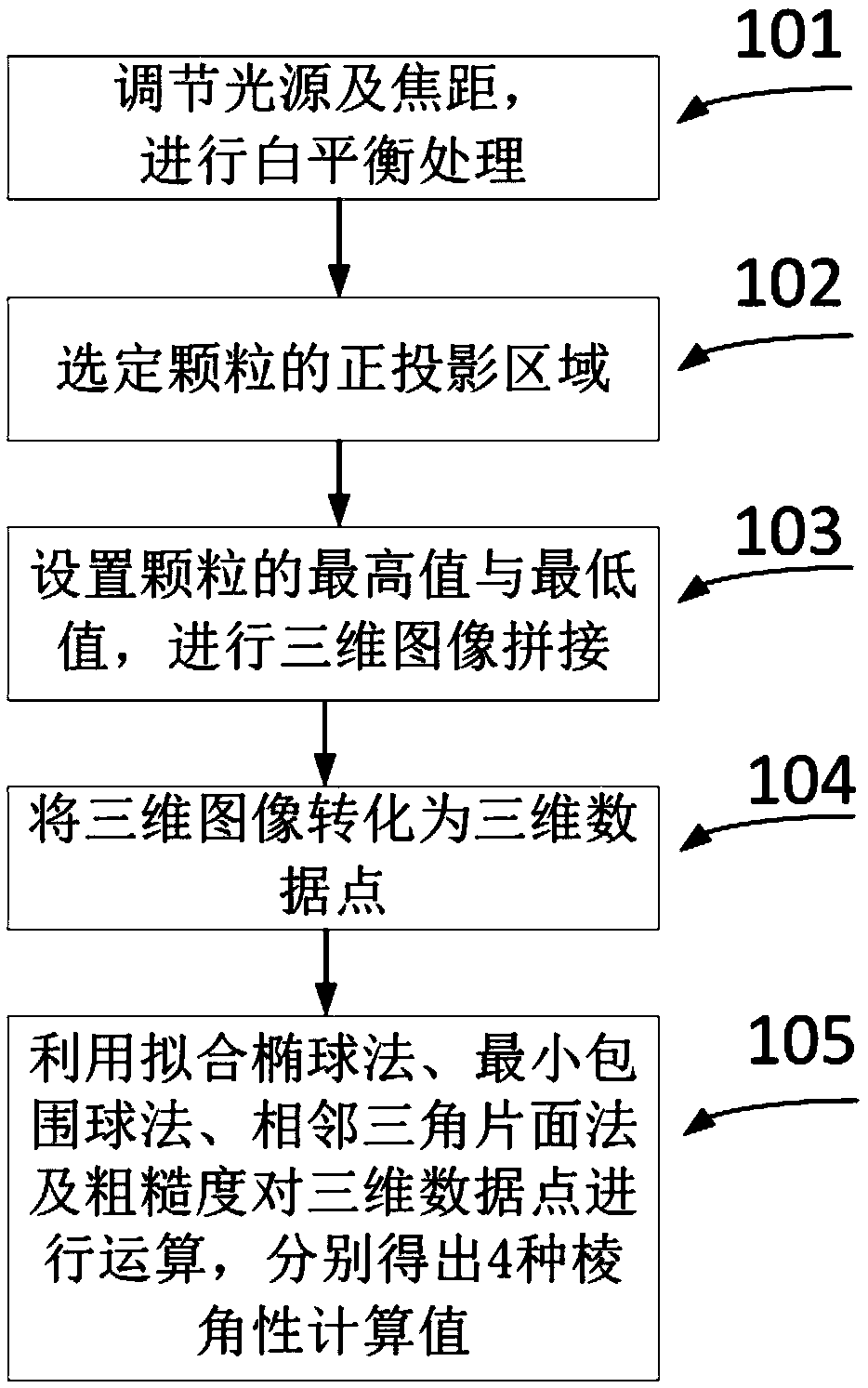

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

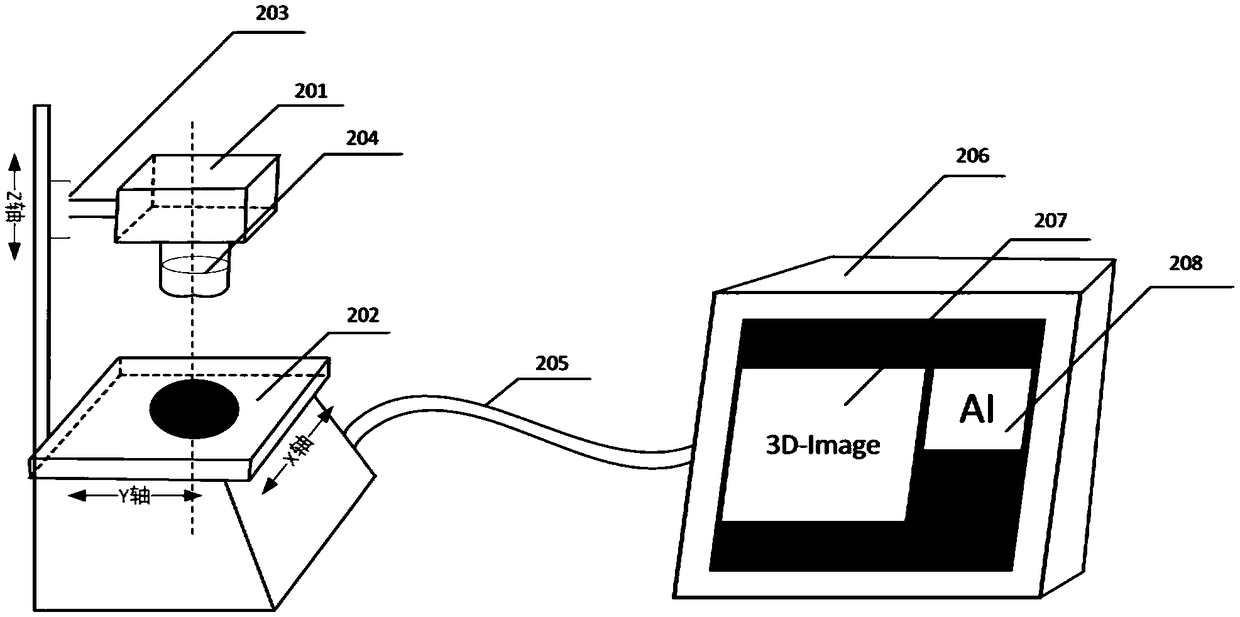

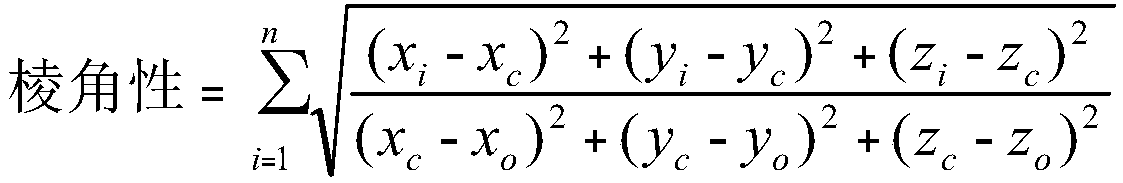

[0035] refer to figure 2 , a three-dimensional angularity detection system, including: a microscope lens module 201, an X / Y-axis electric stage device 202, a Z-axis electric focusing device 203, a three-dimensional image stitching module 207, and an angularity detection module 208, said The microscope lens module 201 includes a general zoom lens, a light source 204 and a camera;

[0036] The Z-axis electric focusing device 203 drives the microscope lens module 201 to move up and down in a direction perpendicular to the upper surface of the X / Y-axis electric stage device 202; the X / Y-axis electric stage device 202 moves along a direction parallel to its upper surface; the microscope lens module 201 is equipped with a light source 204 on one side of the upper surface of the X / Y axis motorized stage device 202;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com