Substation optical cable

A technology for substations and optical cables, applied in the direction of light guides, optics, optical components, etc., can solve the problems of optical cables being easily broken by tension, cable core damage, and optical cable breakage, etc., to achieve good water absorption and water retention, prolong service life, improve The effect of tensile resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

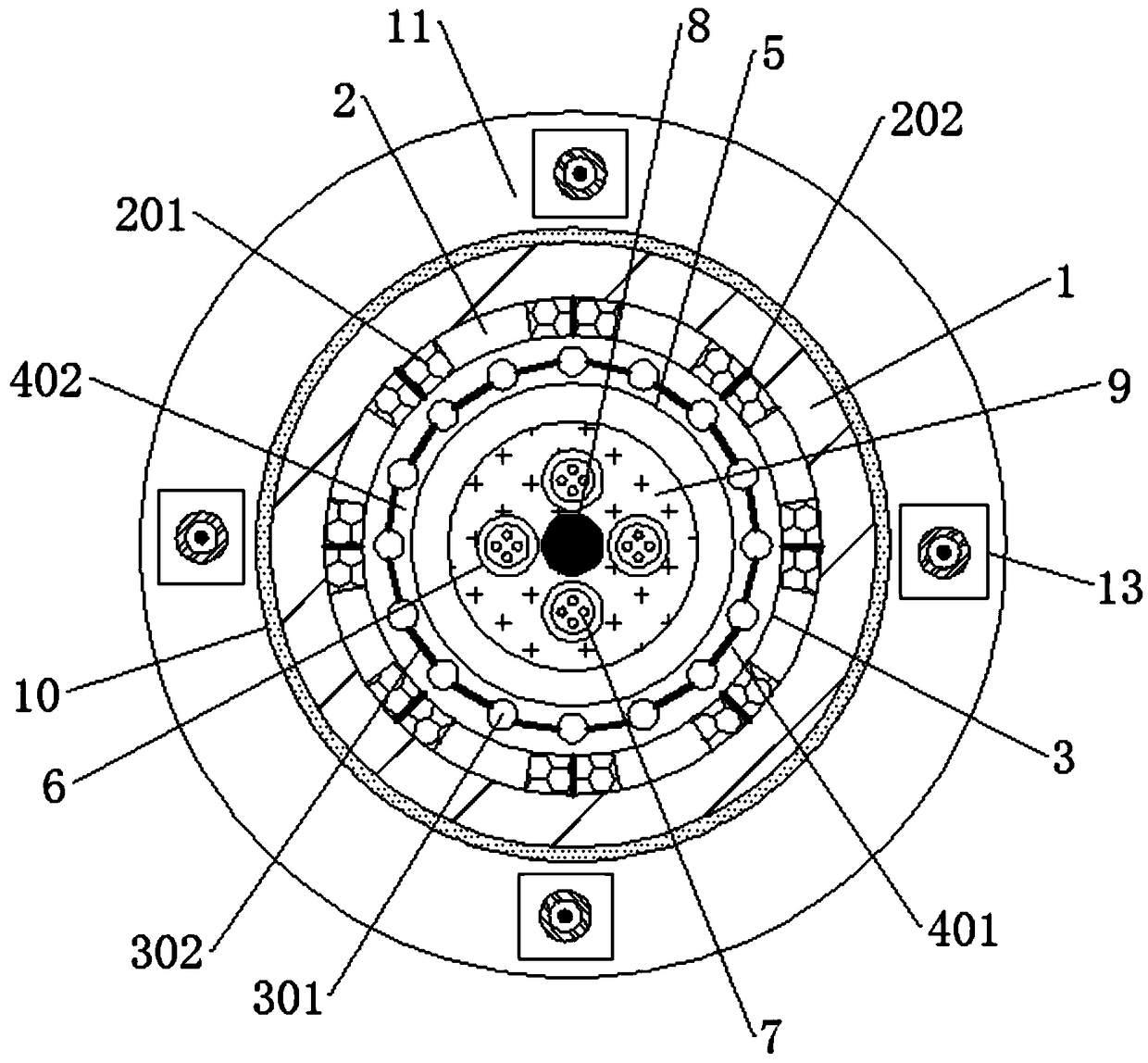

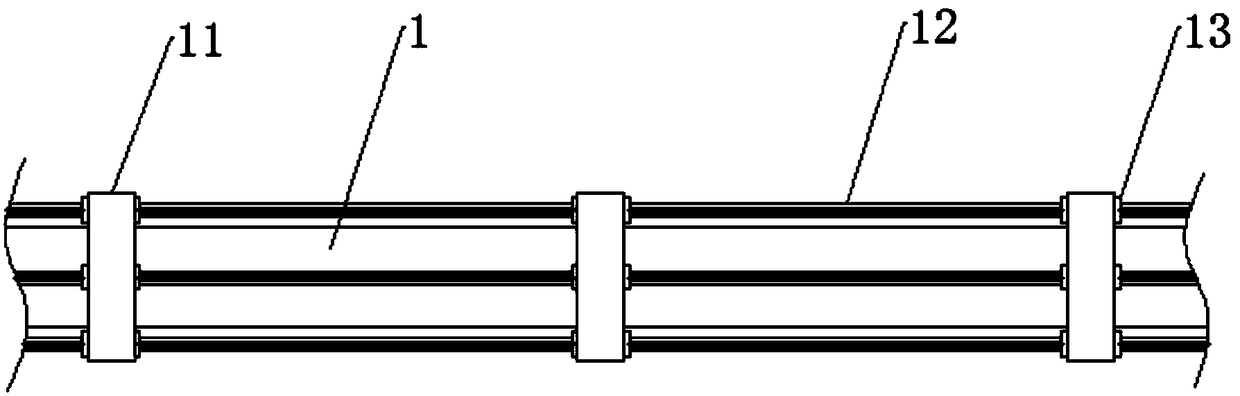

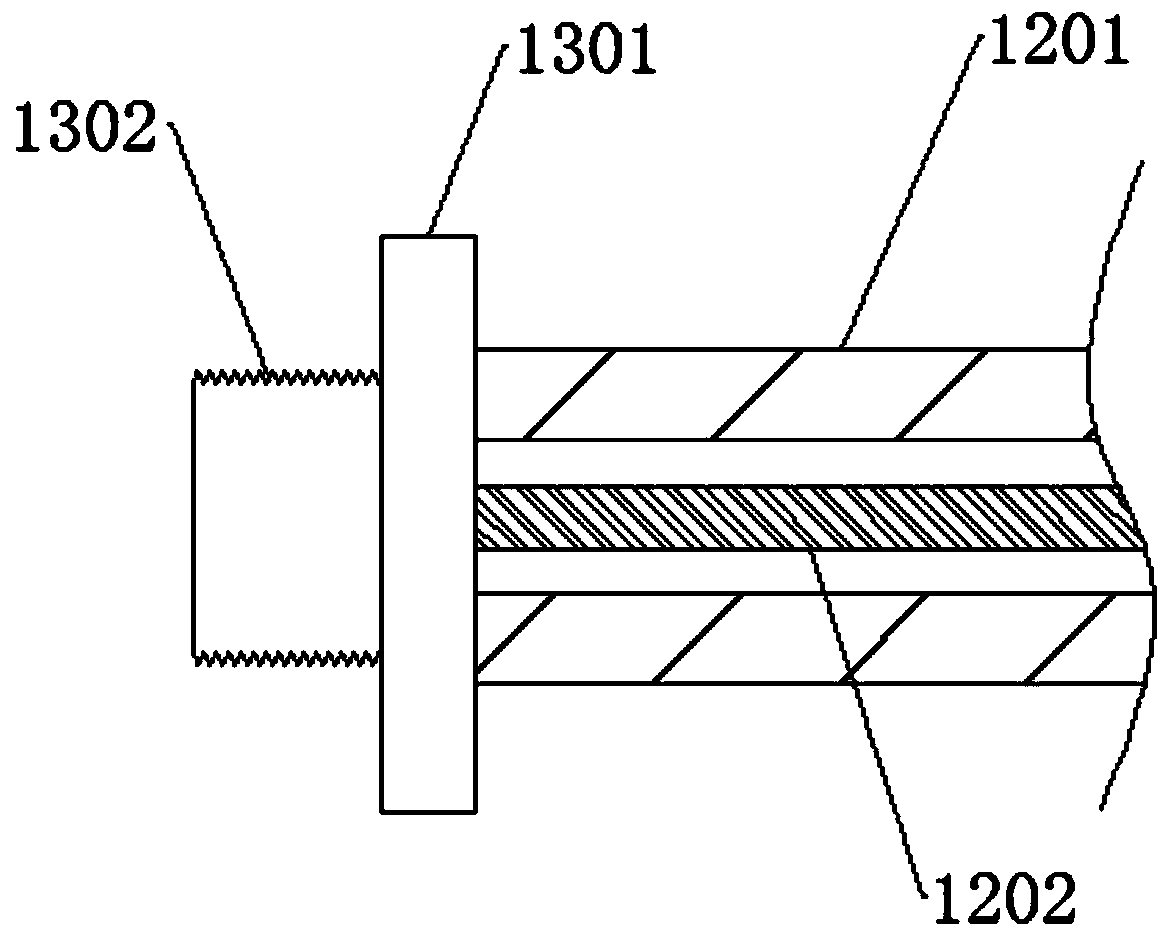

[0031] see Figure 1-3 , a substation optical cable, comprising an outer sheath 1 of the optical cable, which plays the role of basic protection and support, the inner end of the outer sheath 1 of the optical cable is connected with an elastic buffer layer 2, which plays the role of elastic buffer, and the inner end of the elastic buffer layer 2 is connected with The first flame retardant layer 401 plays the role of fire prevention and flame retardancy. The inner end of the first flame retardant layer 401 is connected with the water-proof layer 3 to play the role of water-proof. The inner end of the water-proof layer 3 is connected with the second flame-retardant layer. 402, to further improve the flame retardancy. The inner end of the second flame retardant layer 402 is connected with the inner tube 5 of the optical cable to play an internal protection and support role. The inner tube 5 of the optical cable is provided with a plurality of cable cores 6 distributed in an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com