Slide ring seal arrangement with coated bellows unit

A mechanical sealing device and bellows technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as warping, and achieve the effect of preventing deposition, avoiding tension or warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

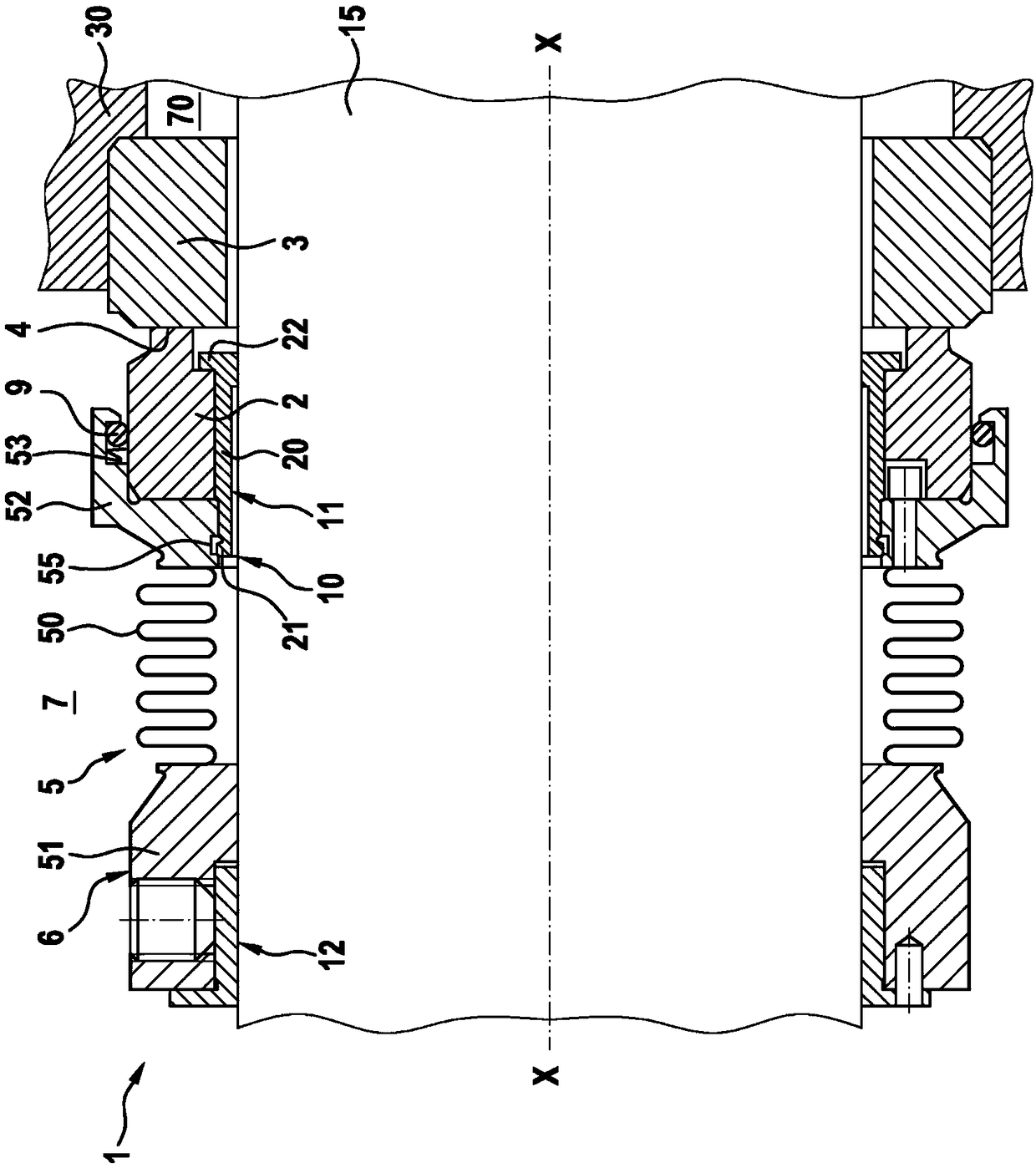

[0025] Hereinafter, the mechanical seal device 1 of the first preferred exemplary embodiment of the present invention will be described in detail.

[0026] as in figure 1 As can be seen in the figure, the mechanical seal device 1 includes a mechanical seal part having a rotary slip ring 2 and a fixed slip ring 3 , and a sealing gap 4 is defined between the rotary slip ring 2 and the fixed slip ring 3 .

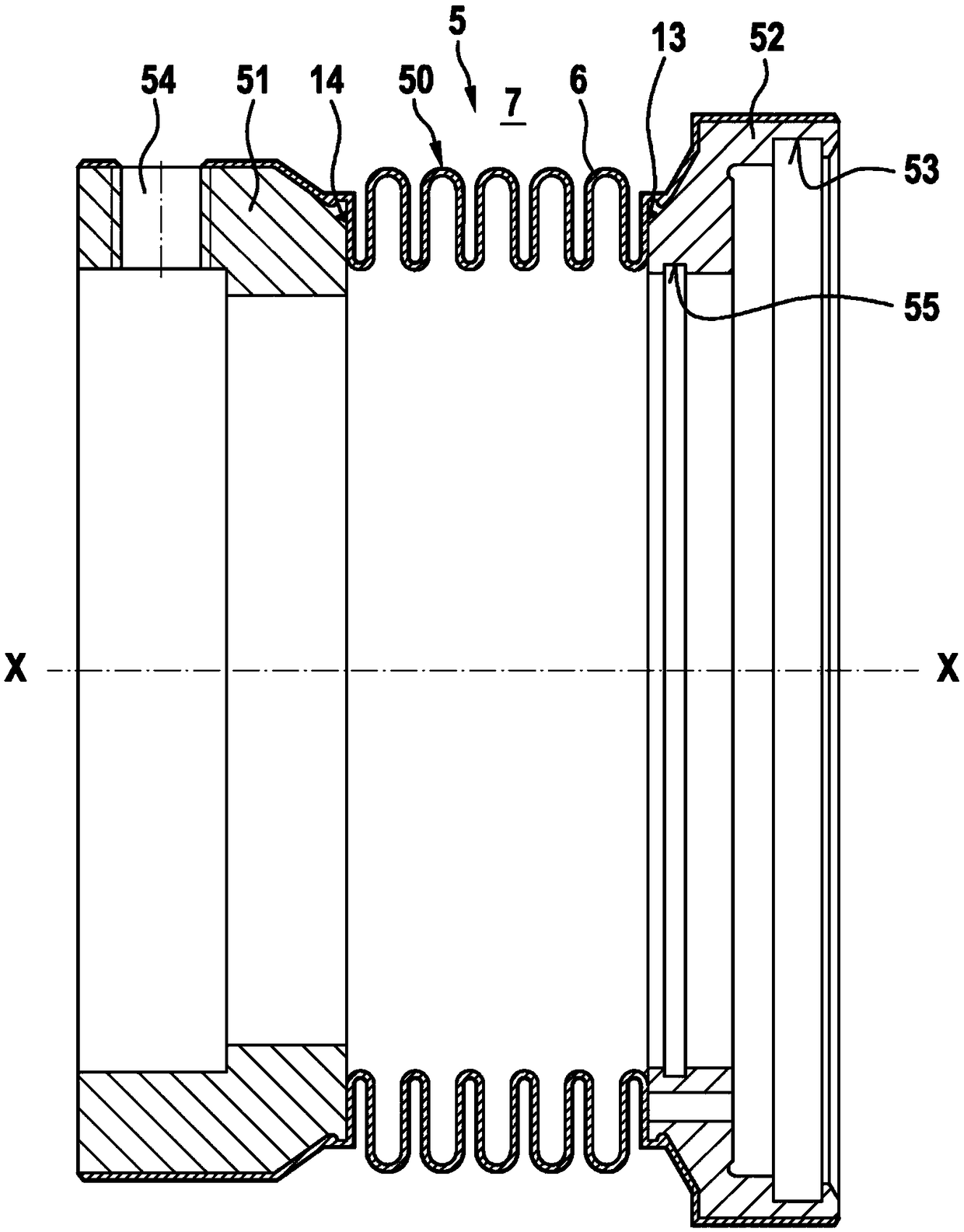

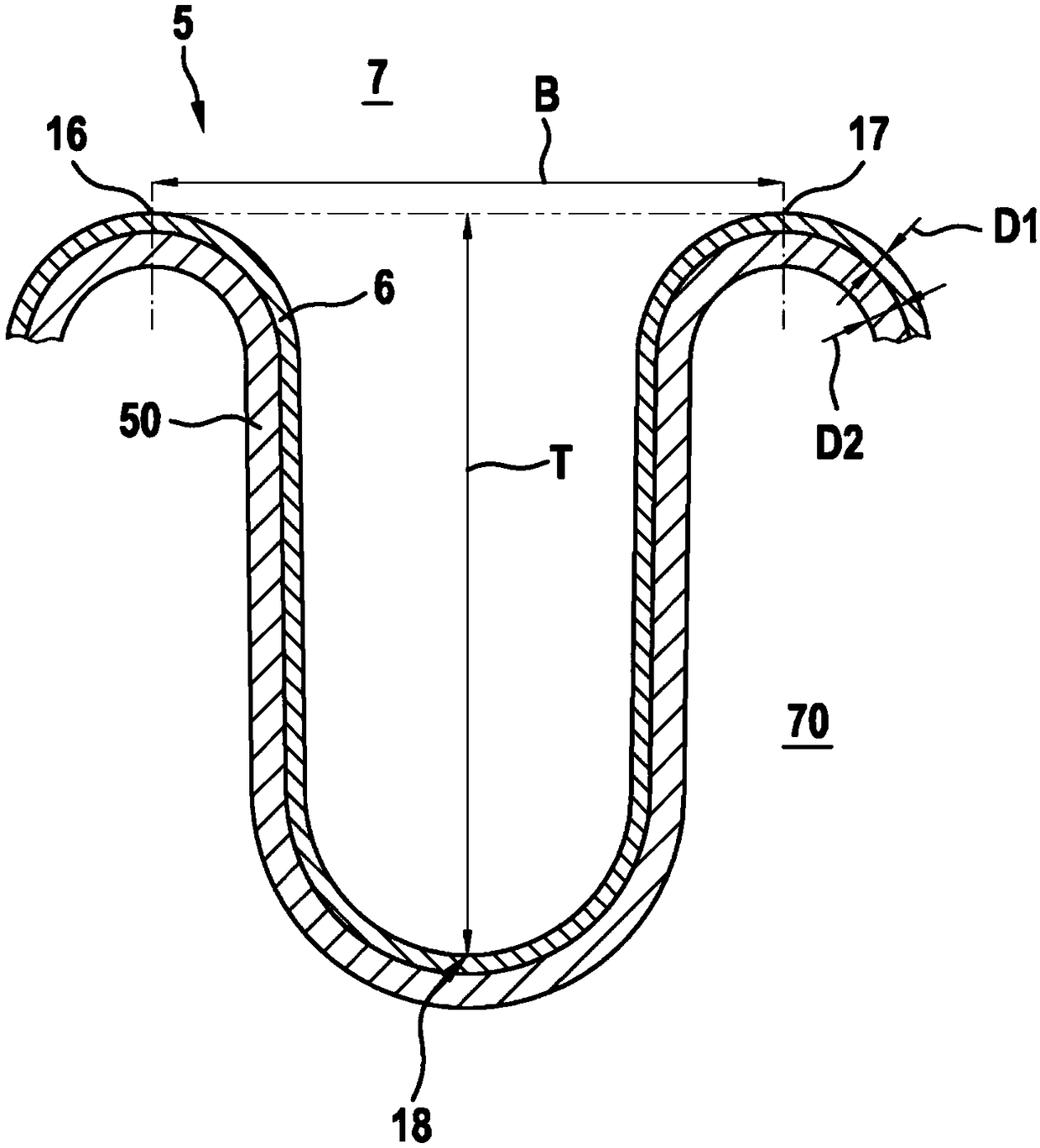

[0027] In addition, the mechanical seal device 1 is included in the figure 2 The bellows unit 5 can be seen in detail in . The bellows unit 5 comprises a flexible bellows element 50 , a bellows support 51 and a slip ring support 52 . The flexible bellows element 50 is a bellows of metallic material, in particular of spring steel material. In this exemplary embodiment, the bellows element is provided as a circular bellows. It is understood that bellows with sharp folds can also be provided as flexible bellows element.

[0028] as in figure 2 As can be seen in , the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com