Efficient coating dispersing machine

A technology for dispersing machines and coatings, applied in mixers, mixers with rotating stirring devices, dissolving, etc., can solve problems such as inability to obtain sufficient mixing and mixing, affect the working efficiency of coating dispersing machines, and low efficiency, and achieve improved cutting Efficiency, reduced work load, sufficient mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

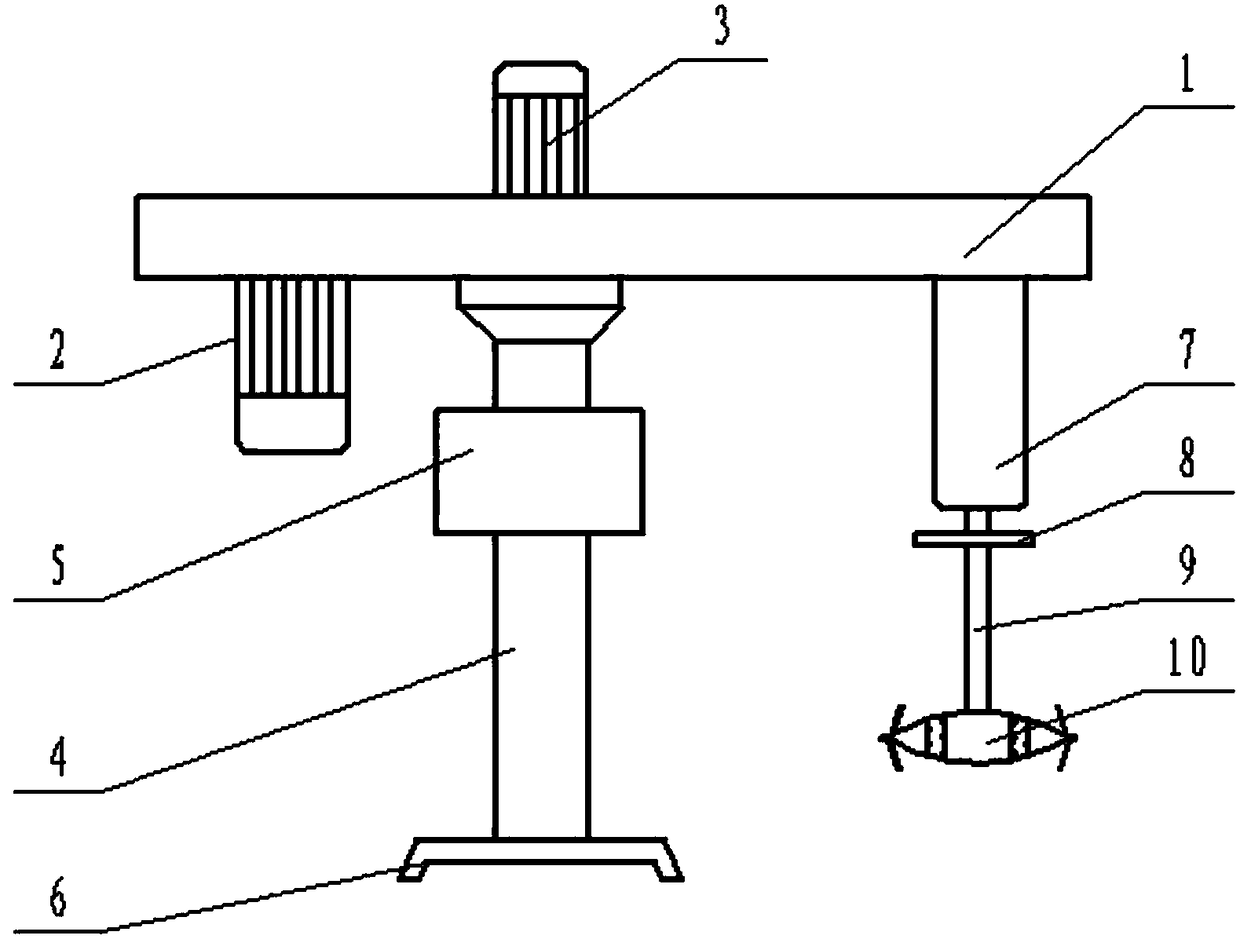

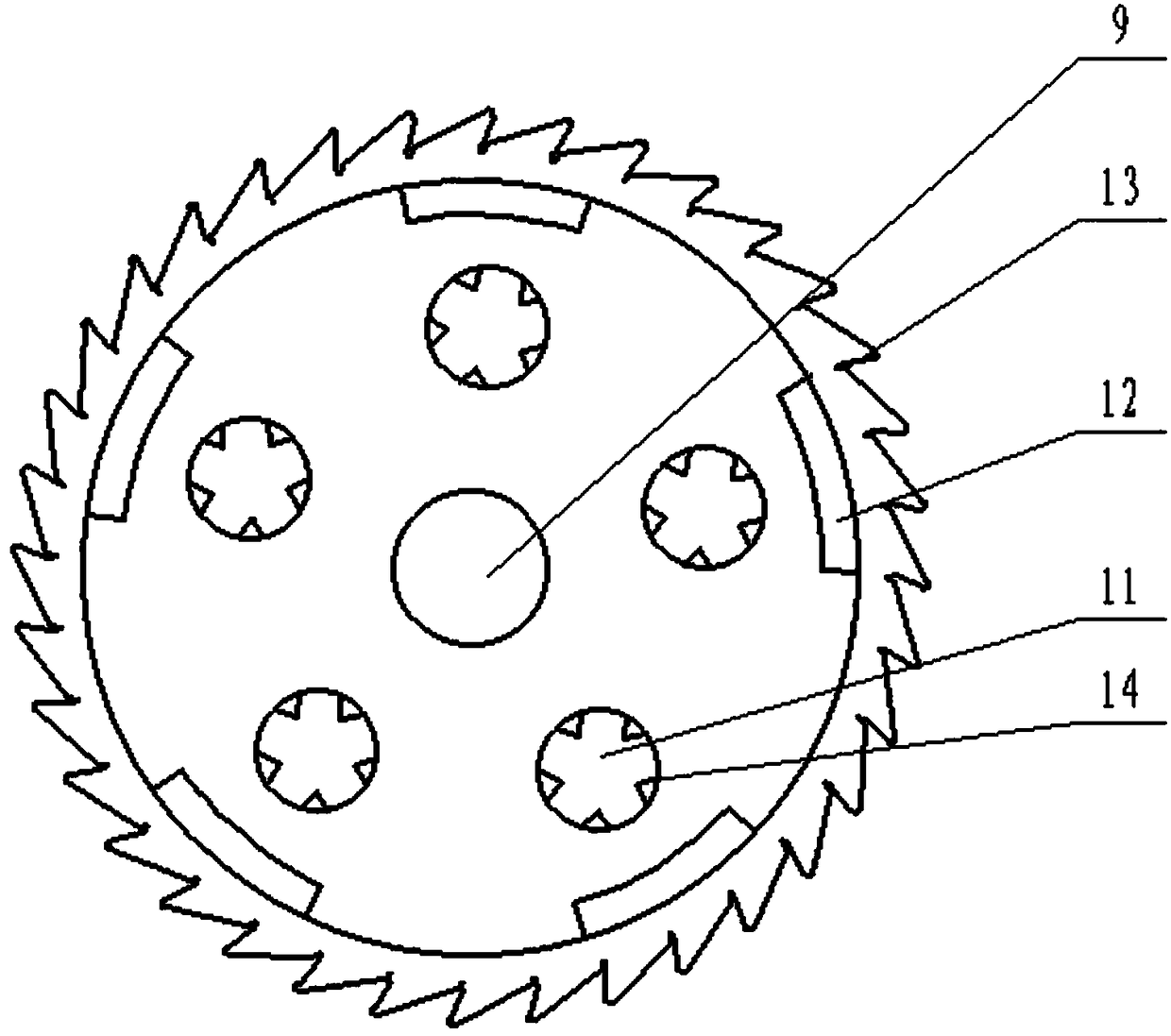

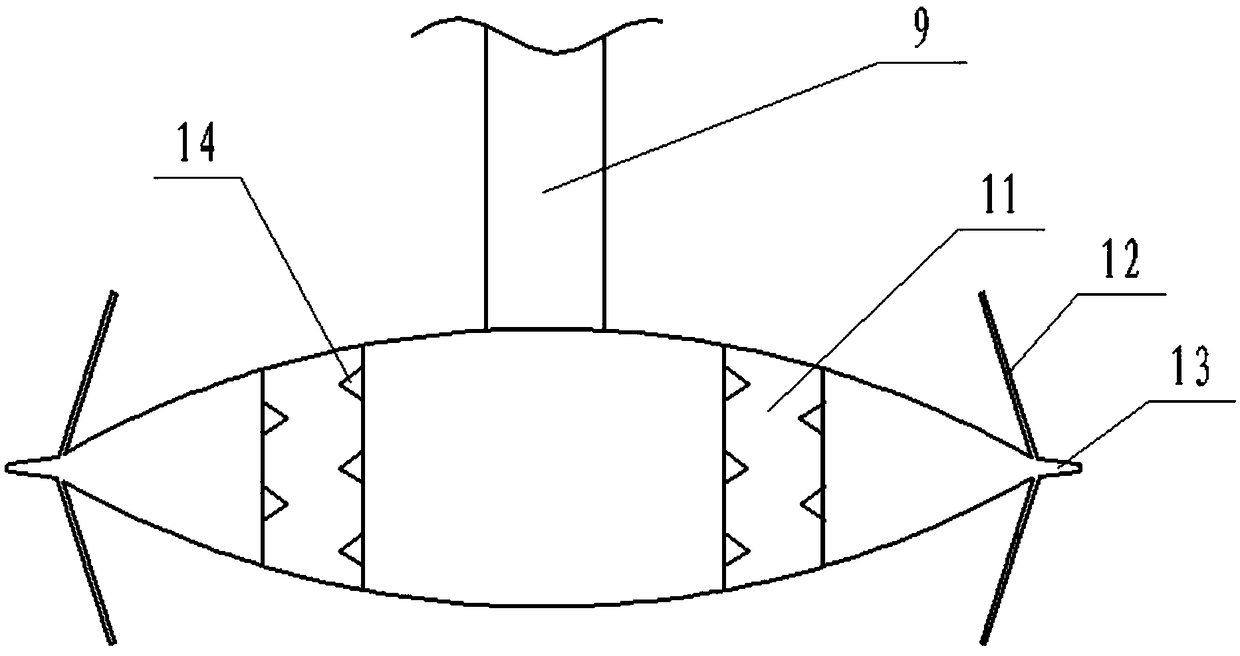

[0014] A high-efficiency paint dispersing machine, including a beam 1, a motor A2, a motor B3, a column 4, a controller 5, a base 6, a shaft seat 7, a flywheel 8, a dispersing shaft 9, a dispersing disc 10, a through hole 11, and a blocking cutting piece 12 , scattered teeth 13, wolf tooth protrusions 14, a motor B3 is arranged on the top of the crossbeam 1, a motor A2 is arranged at one end of the bottom of the crossbeam 1, a column 4 is provided at the middle part of the bottom of the crossbeam 1, a controller 5 is arranged on the column 4, and the bottom of the column 4 A base 6 is provided, and the other end of the beam 1 is provided with an axle seat 7, the lower end of the axle seat 7 is connected with the dispersing shaft 9, and a flywheel 8 is arranged on the dispersing shaft 9, and the bottom end of the dispersing shaft 9 is connected with the dispersing disc 10, and the upper end of the dispersing disc 10 A through hole 11 is opened, and the inner surface of the throu...

Embodiment 2

[0016] When the present invention is actually used, the dispersing disc 10 rotates to stir the slurry, the dispersing teeth 13 cut the slurry, the slurry flows up and down through the through hole 11, and the stirring effect is enhanced. When the slurry passes through the through hole 11, the wolf on the inner surface of the through hole 11 The tooth protrusion 14 cuts the slurry again, and the blocking cutting piece 12 bounces back the slurry impacted on its surface, so that the slurry accelerates to flow through the through hole 11, and the cutting efficiency of the wolf tooth protrusion 14 is improved. When the blocking cutting pieces 12 rotate, the slurry flowing through the blocking cutting pieces 12 is cut to speed up the slurry mixing efficiency. The flywheel 8 makes the high-speed dispersing shaft 9 rotate stably, and finally improves the service life of the dispersing machine.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap