Spiral type leaf throwing roller for wind separating warehouse

A spiral, air separation technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of waste, high leaf content, poor stem and leaf separation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention are described in detail below in conjunction with the embodiments and corresponding drawings, so that those skilled in the art can understand the solutions of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

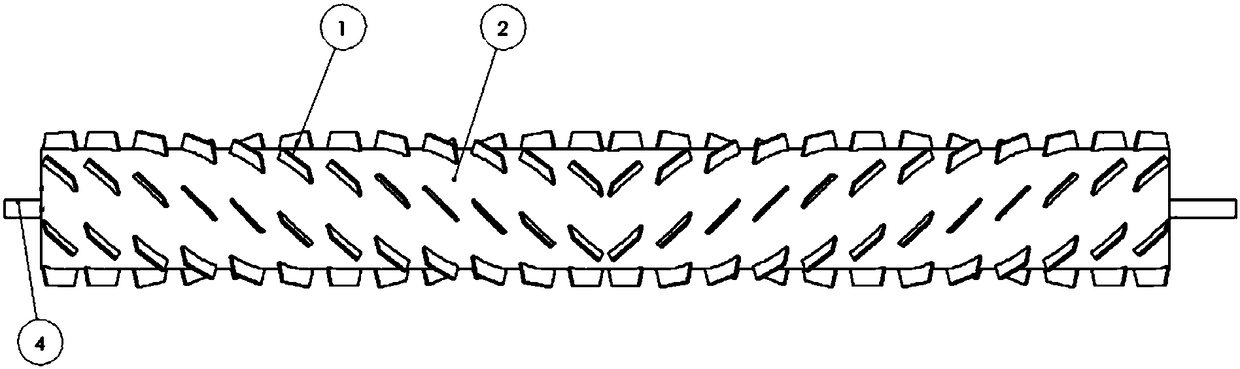

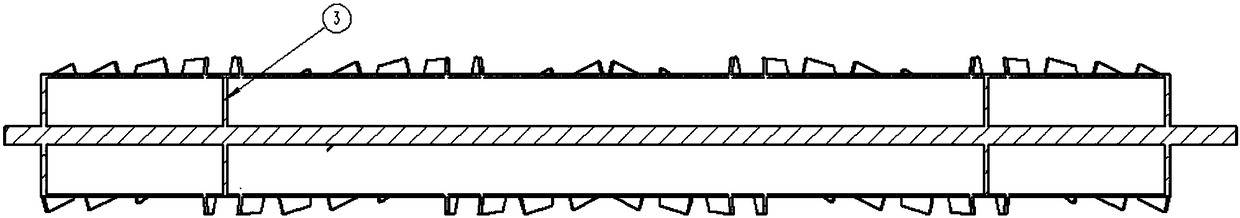

[0026] The invention provides a spiral leaf throwing roller for an air distribution bin. The leaf throwing roller has a hollow structure and has a low weight, which reduces the load on the driving motor. In addition, the position of the thrown materials can be made more uniform, and the airflow can be improved. Divide the effect, reduce the leaf content rate in the stem.

[0027] Specifically, the spiral blade-throwing roller for the air compartment according to the present invention includes a plurality of blades, a roller and a shaft; the plurality of blades are arranged on the outer circumferential surface of the roller, and the shaft passes through at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com