Bamboo rattan or plastic mesh weaving machine and weaving method thereof

A technology of plastic mesh and weaving machine, which is applied in the direction of braiding, mechanical equipment, textiles and papermaking, etc., and can solve the problems of low efficiency, loose weaving of warp threads, and undiscovered problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

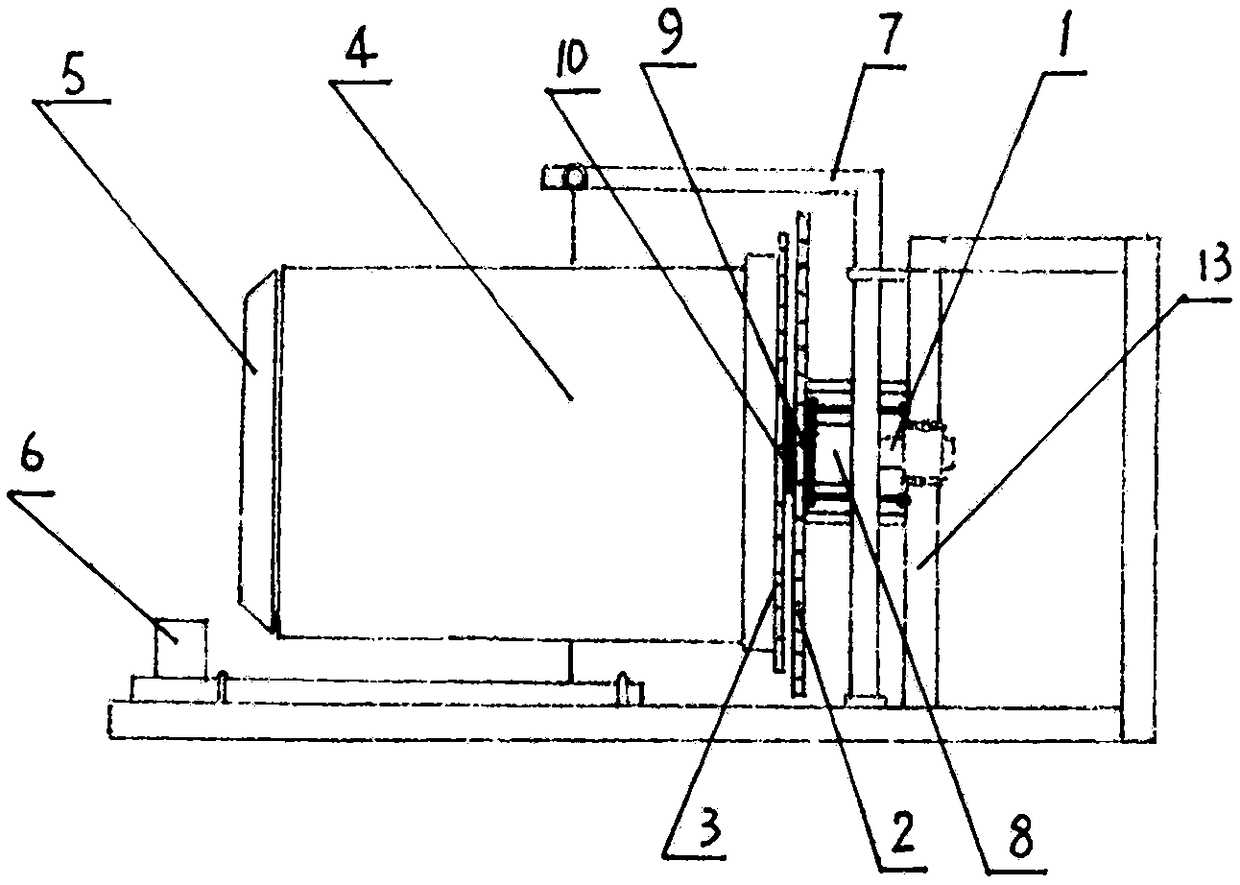

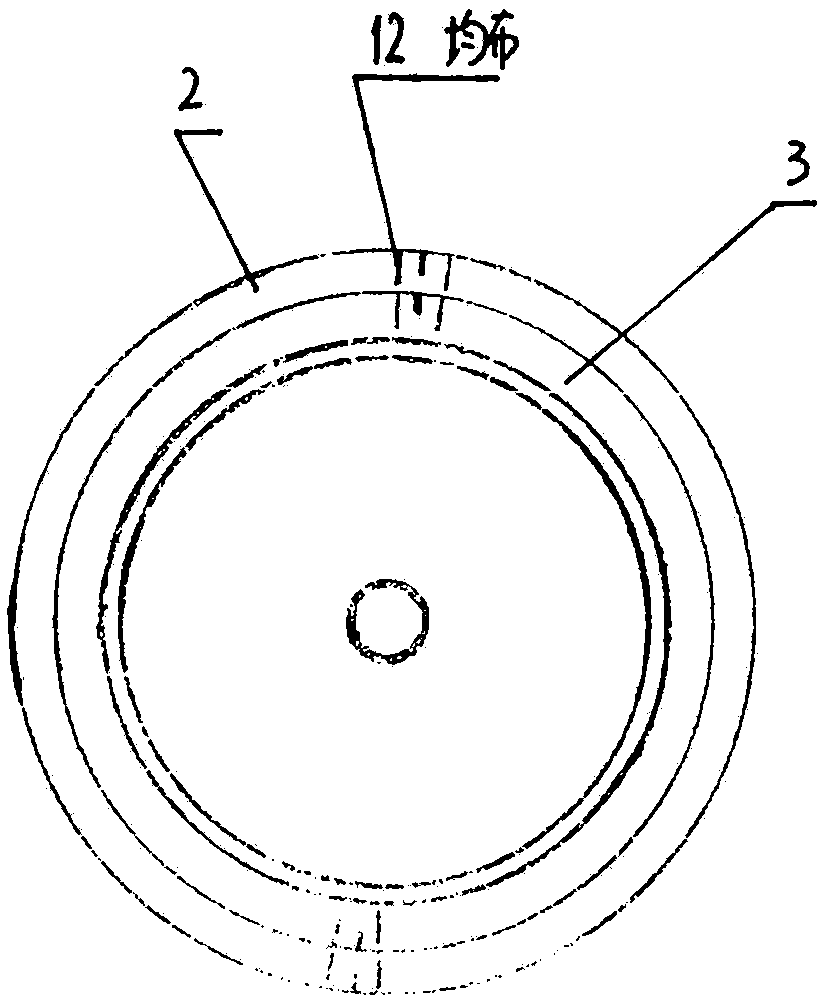

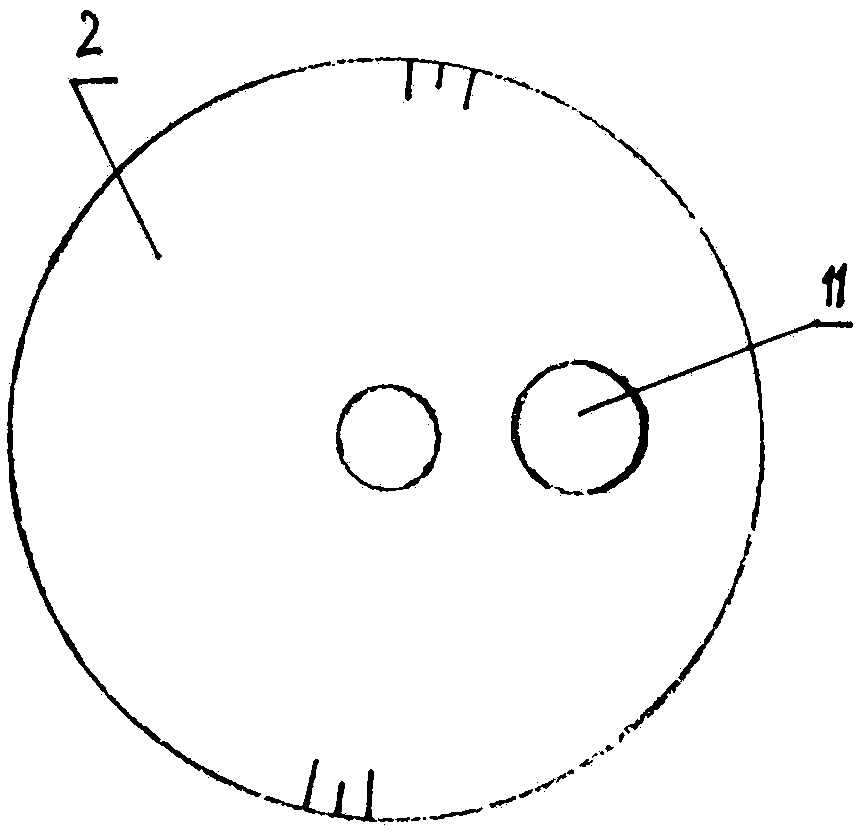

[0018] figure 1 Among them, a bearing seat is set on the bracket, the shaft 1 is installed on the bearing seat, the fixed plate 2, the movable plate 3 and the mold body 4 are installed on the shaft 1, another bearing is installed in the mold body 4 to connect the shaft 1, and the fixed plate 2. It is fixedly connected to the bracket 13 through fasteners. The mold body 4 is movably connected to the mold head 5. The mold body 4 or the mold head 5 can be replaced according to the weaving requirements. A pedal 6 is set at a position convenient for the operator to step on, and the pedal 6 passes through the Link mechanism 7 connects lug 8, and lug 8 can be protrusion, can be eccentric wheel, can also be eccentric tube, and it is fixed on the working shaft of link mechanism 7 corresponding with movable top plate 9, and Movably cooperate with the movable top plate 9, the mov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap