Acetate fiber pull-apart device and production method

A technology of acetate fiber and breaking device, which is applied in the direction of fiber cutting, fiber processing, and fiber bundle into fiber sliver/yarn, etc., which can solve the problem of acetate fiber damage, sliver length distribution, and acetate fiber filament. To avoid problems such as beam breaking and sliver making, to improve the quality of sliver and eliminate the effect of abnormal draft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

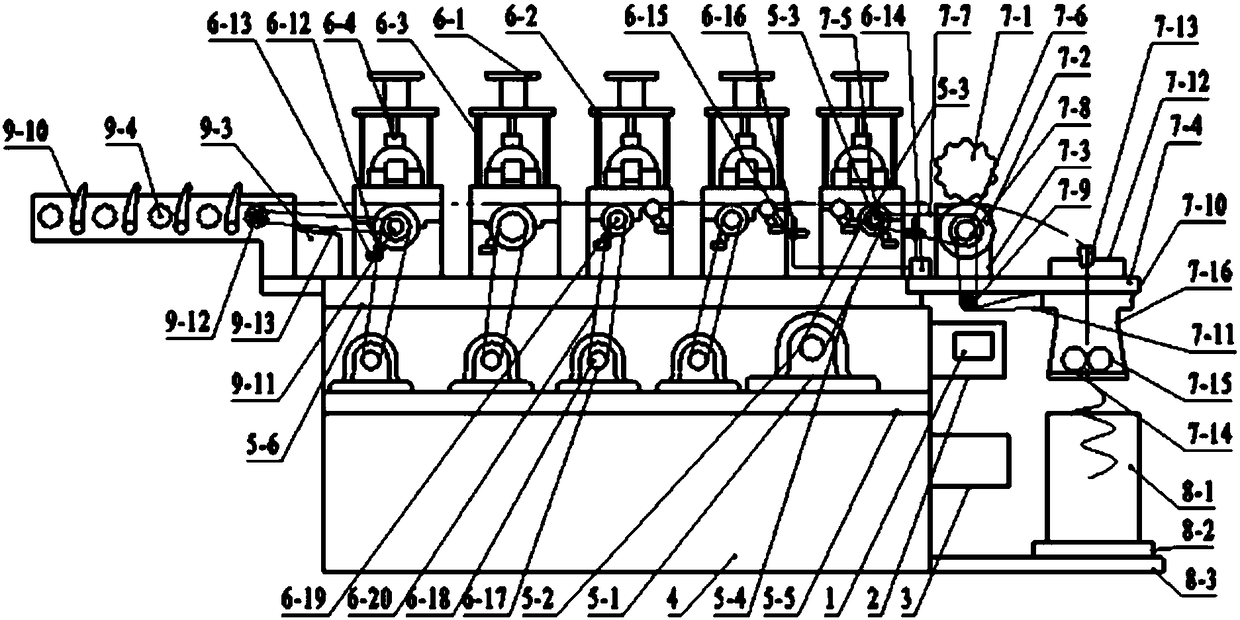

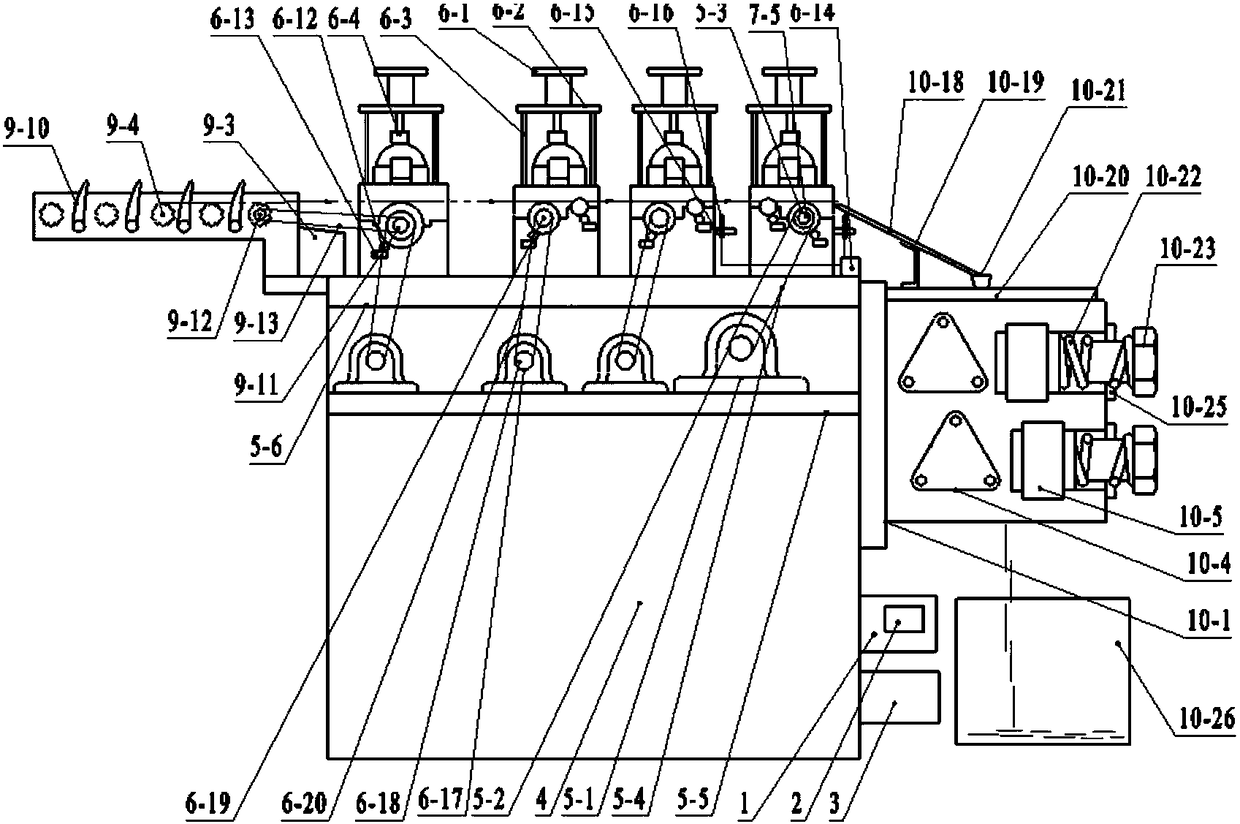

[0052] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

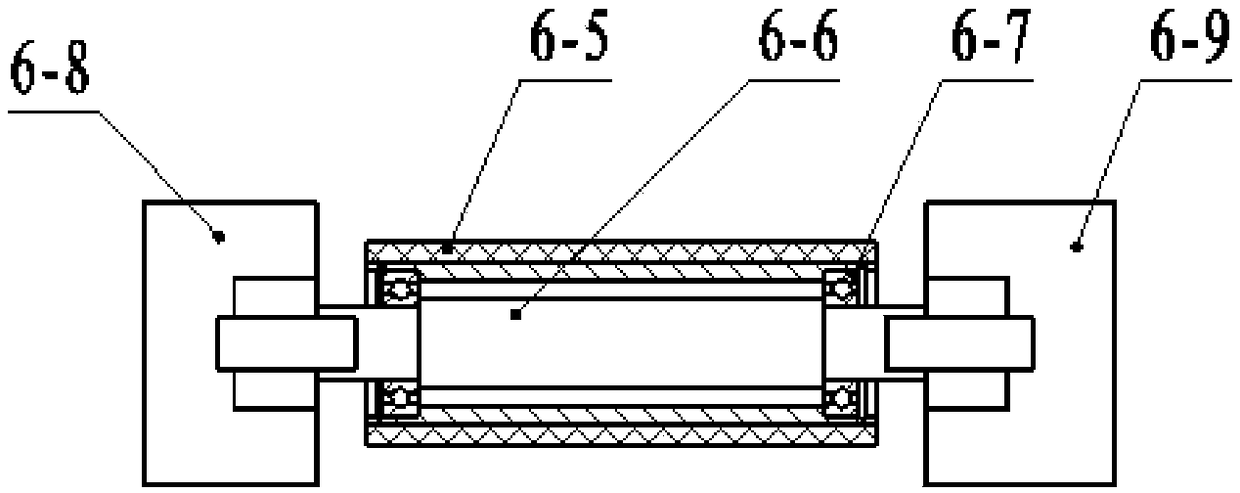

[0053] to combine figure 1 and figure 2 As shown, the present invention provides a breaking device for cellulose acetate, comprising a machine interface 1, a casing 2, a program controller 3, a frame 4, a main transmission mechanism 5, a drafting and pressing mechanism 6, an upper coil mechanism 7, Coiling mechanism 8, drum feeding mechanism 9 and loose wool mechanism 10 under. specifically:

[0054] Such as figure 1 As shown, the main transmission mechanism 5 includes a main servo motor 5-1, a transmission sprocket 5-2, a transmission sprocket 5-3, a transmission chain 5-4, a servo motor fixed plate 5-5, and a roller stool 5-6, wherein , the transmission sprocket 5-2 is placed on the main servo motor 5-1, the transmission sprocket 5-3 is driven by the transmission chain 5-4 and the transmission sprocket 5-2, and the servo motor fixing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com