Sequence valve

A sequence valve and valve body technology, applied in the field of hydraulic machinery, can solve the problems of increasing pipeline leakage, increasing operating time and labor intensity, and achieving the effect of reducing the risk of leakage, reducing installation time and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

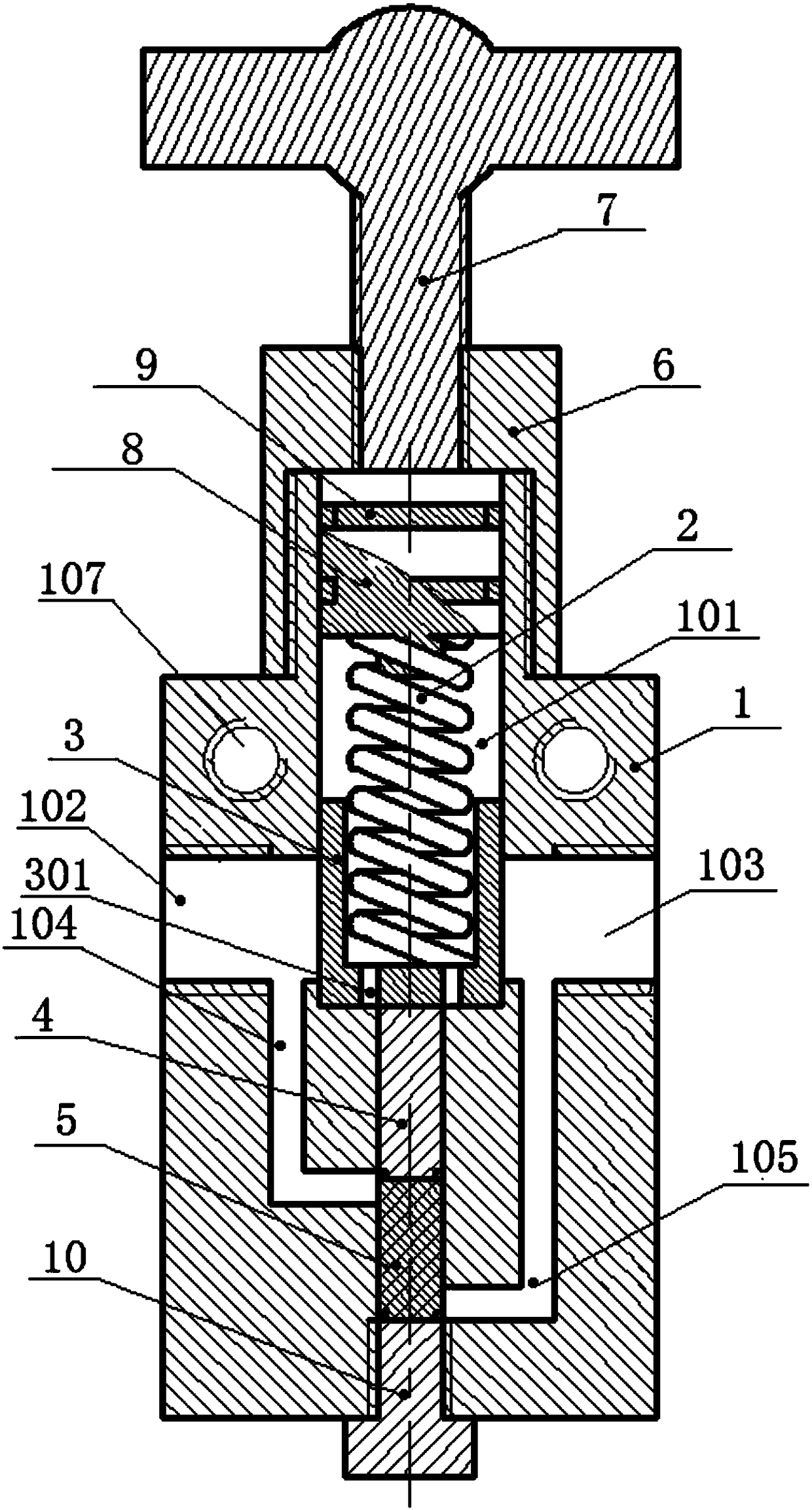

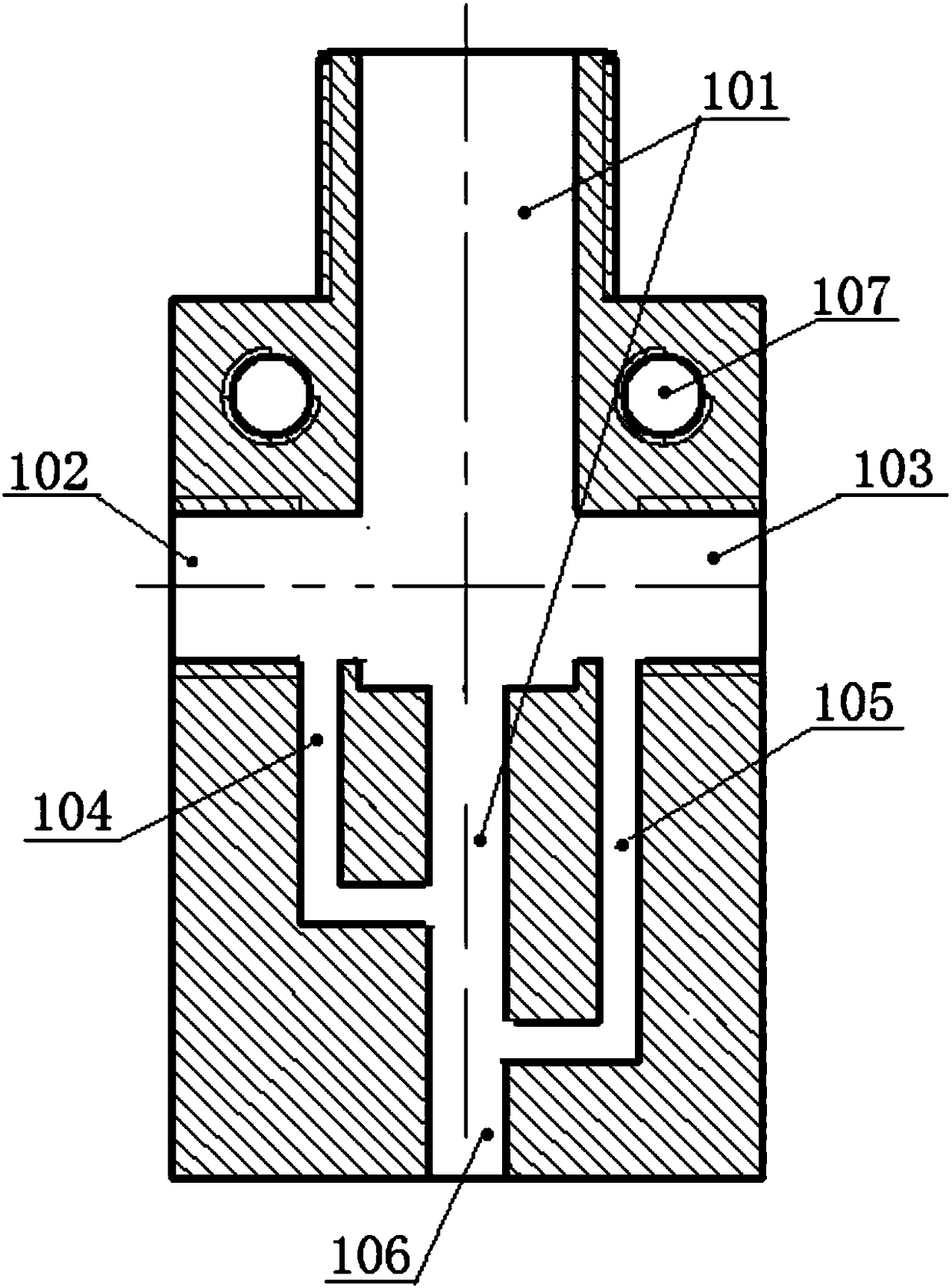

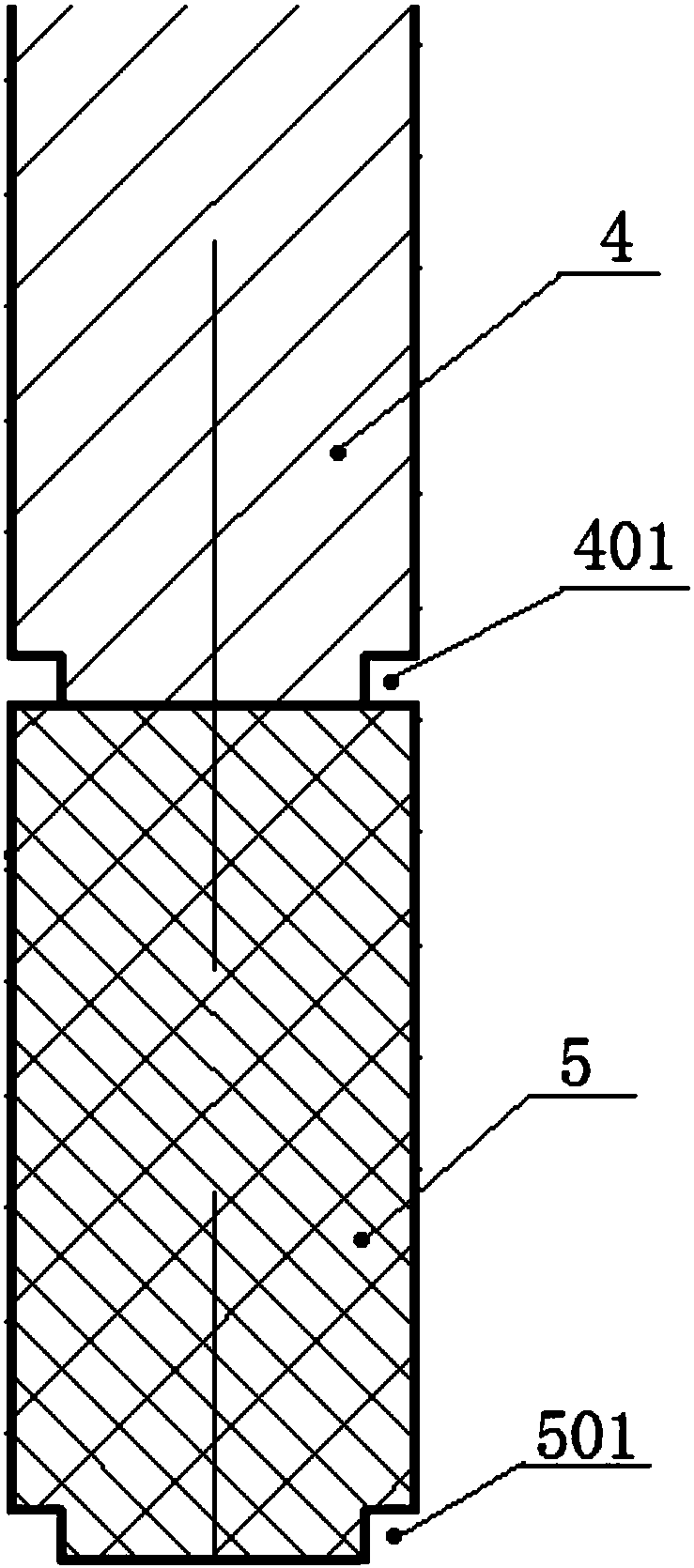

[0068] The embodiment of the present invention provides a sequence valve, such as figure 1 As shown, the sequence valve includes: a valve body 1 with a first cavity 101 along the axial direction, a spring 2 that is offset from top to bottom and arranged in the first cavity 101, a plunger 3 for breaking, a second One unlatching plunger 4, the second unlatching plunger 5. Further, see figure 2 , the left and right side walls of the valve body 1 are respectively provided with a first oil port 102 and a second oil port 103 communicating with the first cavity 101; the spring 2 is always in a compressed state; The inner wall of the first cavity 101 dynamically seals and slides, and is used to block and connect the first oil outlet 102 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com