Stepless shift baffle pin board

A technology of pin plate and displacement, which is applied in the field of construction equipment to achieve the effects of convenient processing, reduced frictional resistance, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

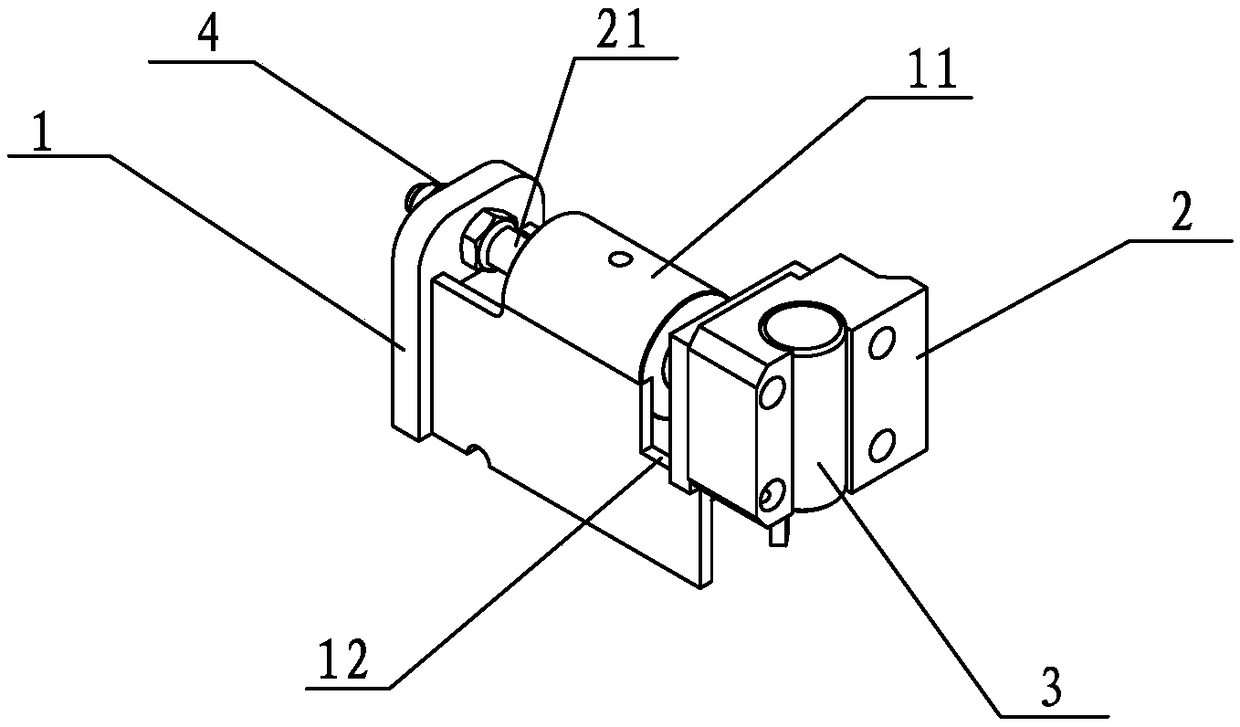

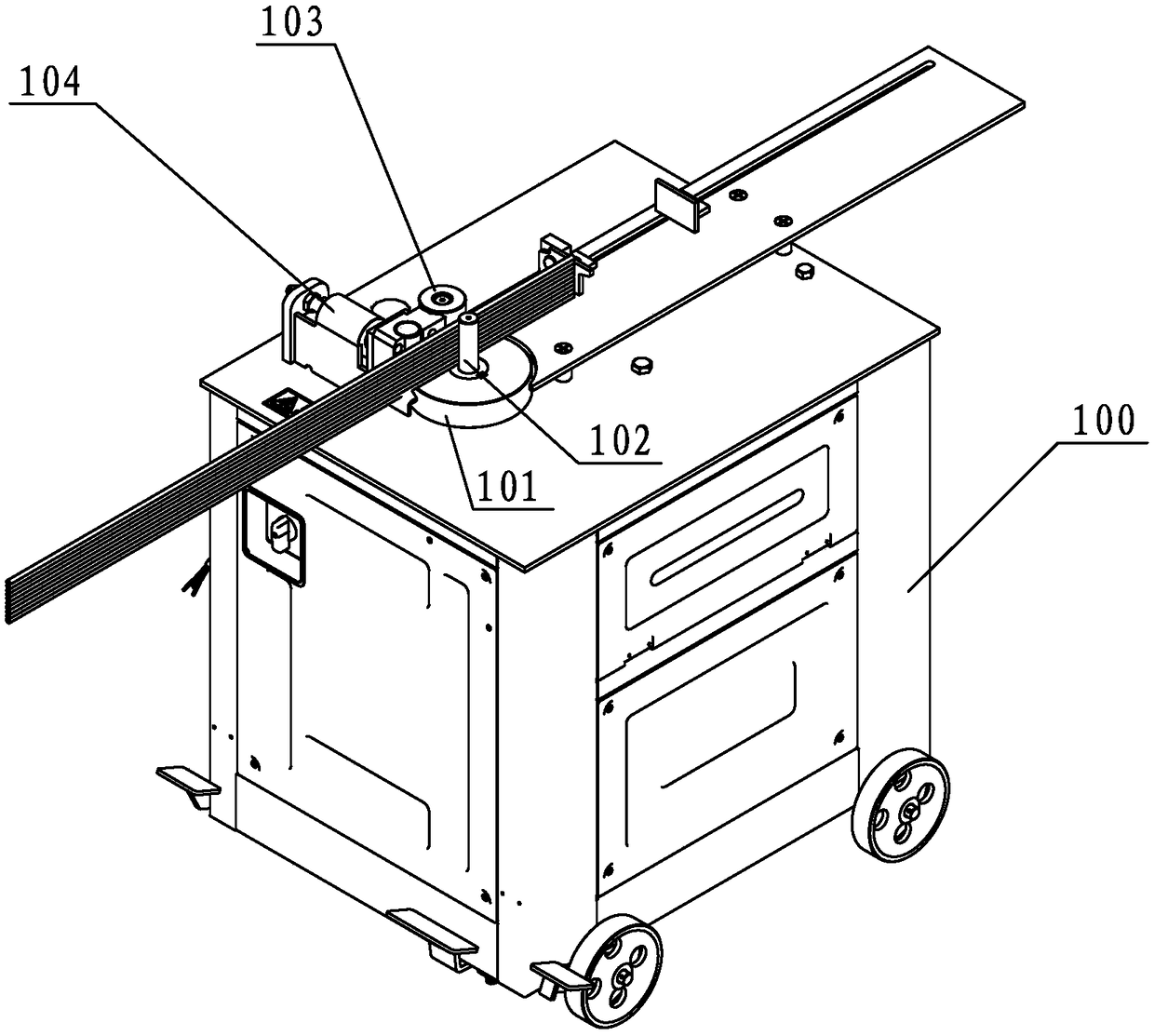

[0022] refer to figure 1 , the present invention provides a preferred embodiment of the stepless shift pin plate, including a positioning support 1, the positioning support 1 is provided with a shaft hole, the positioning support 1 is connected with a slide rail plate by welding, and the slide rail plate A flange bushing 11 is welded and fixed on the top, and a limit slide rail 12 is arranged in front of the slide rail plate. A stop pin plate 2 is slidably arranged on the limit slide rail 12, and a flange shaft 21 is arranged at the rear of the pin stop plate 2, and the flange shaft 21 passes through the flange bushing 11 and the shaft hole in turn, and is locked by the adjusting nut 4, The flange shaft 21 is provided with threads that match the adjusting nut 4, and the front and rear positions of the pin stop plate 2 can be easily adjusted by turning the adjusting nut 4. The front end of the pin stop plate 2 is provided with an arc-shaped groove, and the arc-shaped groove A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com