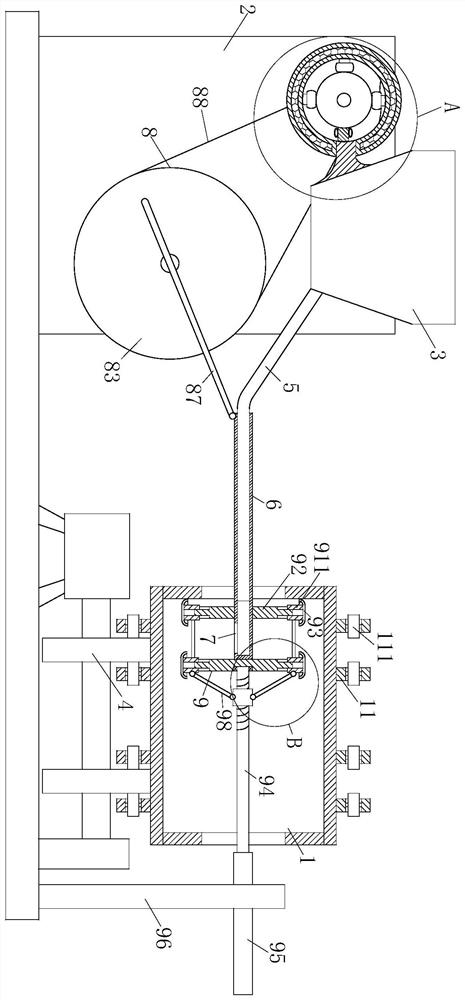

A multifunctional centrifugal casting machine

A centrifugal casting machine and multi-functional technology, applied in the field of casting equipment, can solve the problems affecting the production efficiency of the centrifugal casting machine, the low flatness of the inner wall of the tubular casting, and the low strength of the tubular casting, so as to reduce its own stress, improve the strength and improve the time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

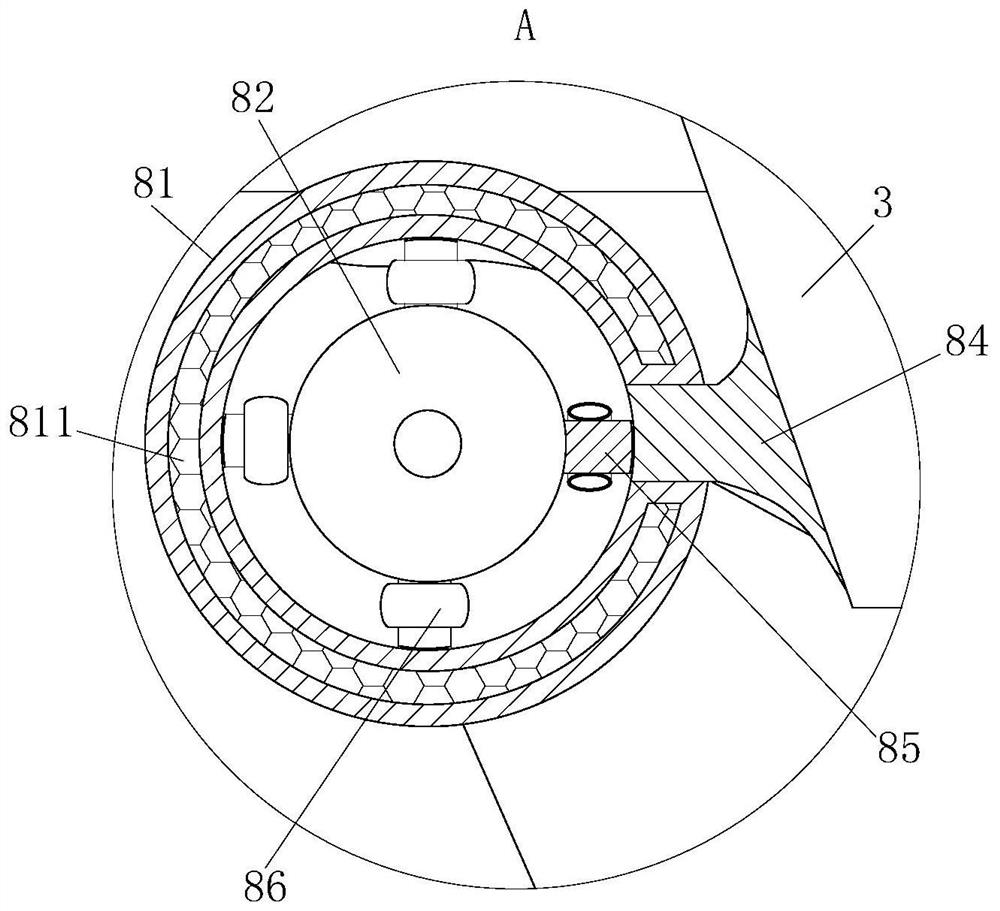

[0026] As an embodiment of the present invention, the tank wall of the water tank 81 is a hollow structure, and the inside of the tank wall of the water tank 81 is filled with a heat insulating material 811, which is used to reduce the influence of the surrounding high temperature environment on the water temperature in the water tank 81; It can maintain a good cooling effect when used for a long time.

[0027] As an embodiment of the present invention, four protruding rings 11 are arranged on the molded cylinder 1, and the protruding rings 11 are arranged on both sides of the supporting roller 4. The protruding rings 11 are used to prevent the supporting roller 4 from derailing. A wheel 111 is provided for rotation; the wheel 111 is rollingly connected with the support wheel 4 , and the wheel 111 is used to reduce the friction between the support wheel 4 and the support wheel 4 . When the cylinder 1 rotates at high speed, the wheel 111 rotates on the support roller 4, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com