Full-automatic vibrating device for conductive concrete specimens

A conductive concrete, fully automatic technology, used in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problem of uneven distribution of conductive concrete admixtures, improve economic benefits and work efficiency, uniform distribution, and economical The effect of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments.

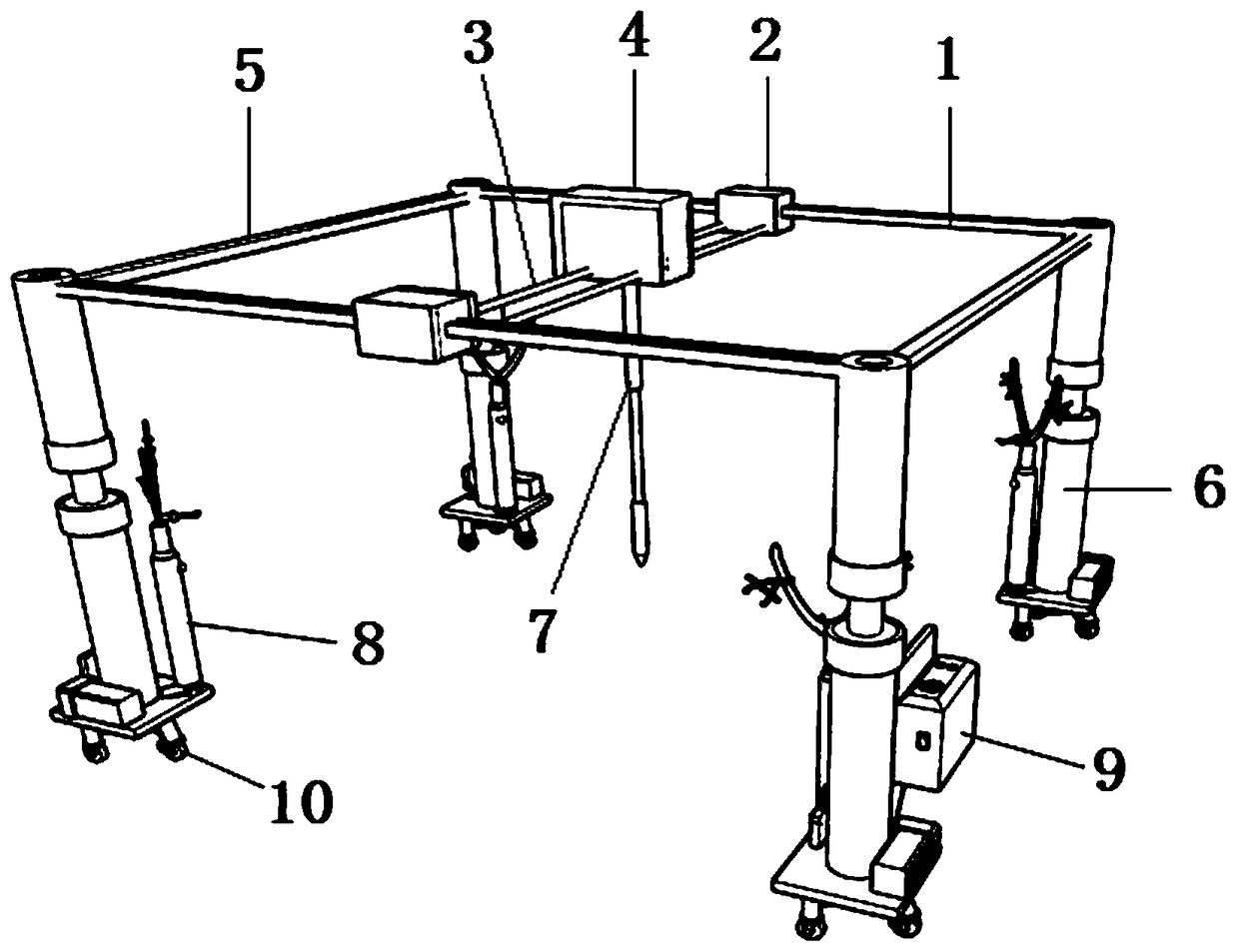

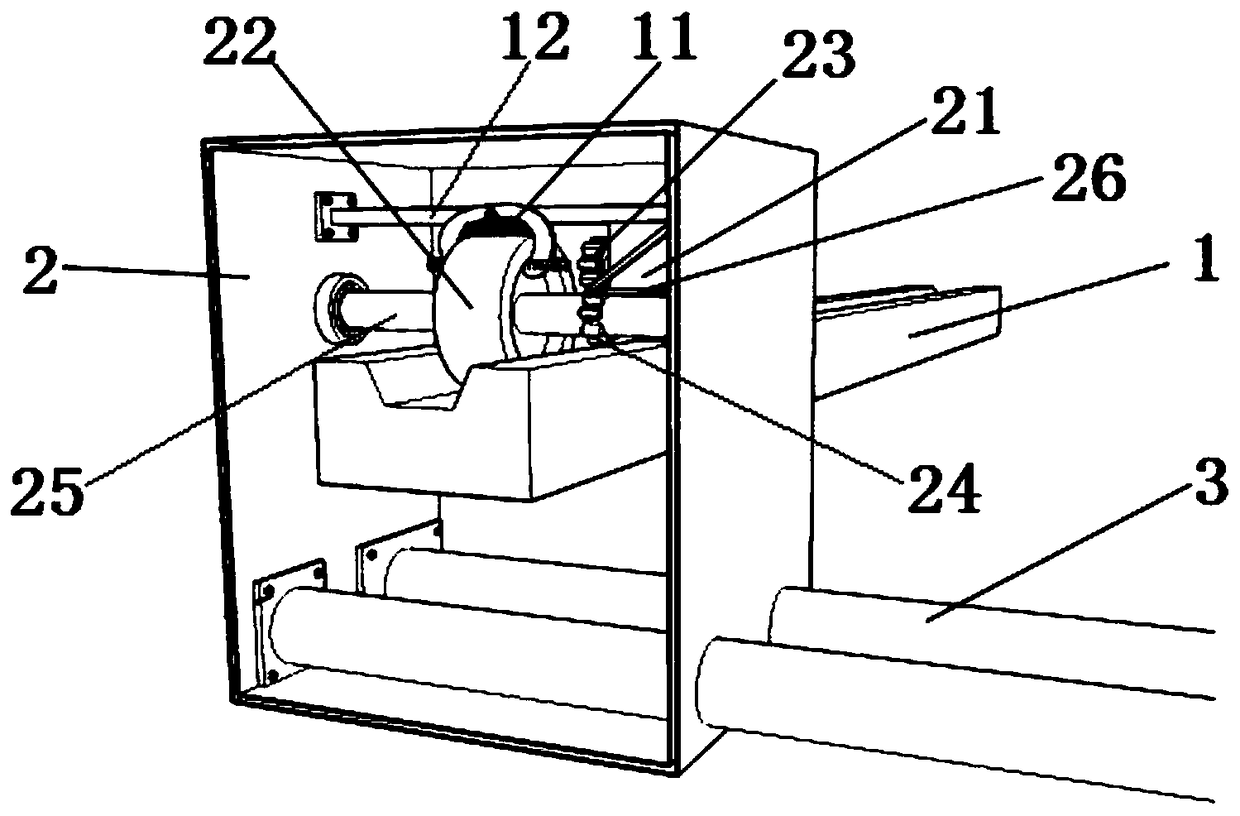

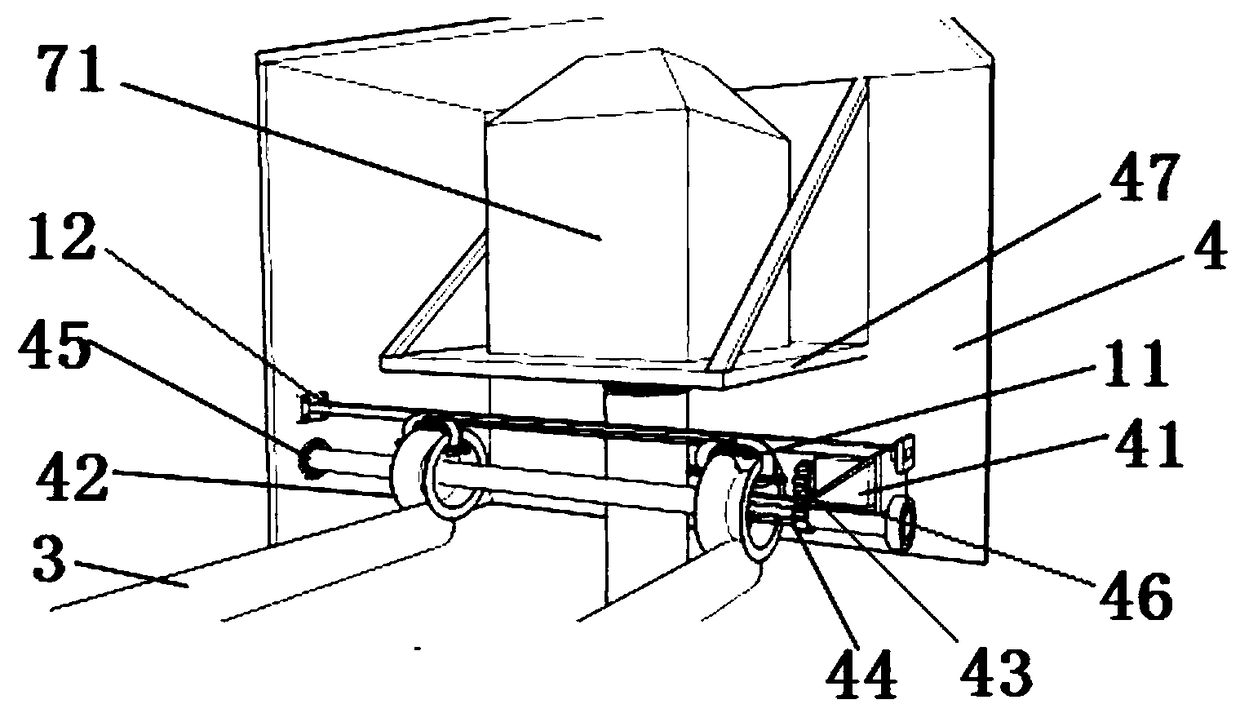

[0031] see figure 1 A fully automatic vibrating device for conductive concrete specimens is shown, including a horizontal moving track 1, a horizontal moving box 2, a longitudinal moving track 3, a longitudinal moving box 4, a vertical fixed rod 5, a hydraulic lifting column device 6, and a vibrating rod 7. The mold fixing device 8, the control device 9 and the moving device 10; the horizontal moving track 1 and the vertical fixed rod 5 are arranged perpendicular to each other to form a square frame; the horizontal moving box 2 is nested on the horizontal moving track 1 arranged in parallel , move along the direction of the transverse moving track 2; the longitudinal moving track 3 parallel to the longitudinal fixed rod 5 is fixedly connected between the transverse moving boxes 2; the longitudinal moving box 4 is nested on the longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com