Escalator assembly mobile carrying device

A carrier device and escalator technology, which is applied in transportation and packaging, conveyors, metal processing, etc., can solve the problems of escalator ladder debugging interference, affecting the service life of the escalator, and hidden safety hazards, and achieves low production costs, convenient operation, and The effect of improving safety

Pending Publication Date: 2019-03-08

GUANGZHOU GUANGRI ELEVATOR IND

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, most of the escalator transfers between stations are still carried out by cranes. This method not only has low work efficiency, but also has potential safety hazards. After each hoisting, it is affected by the unevenness of the ground between stations, which may easily lead to Escalator ladder road debugging interference, resulting in abnormal noise and wear, affecting the service life of the escalator

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

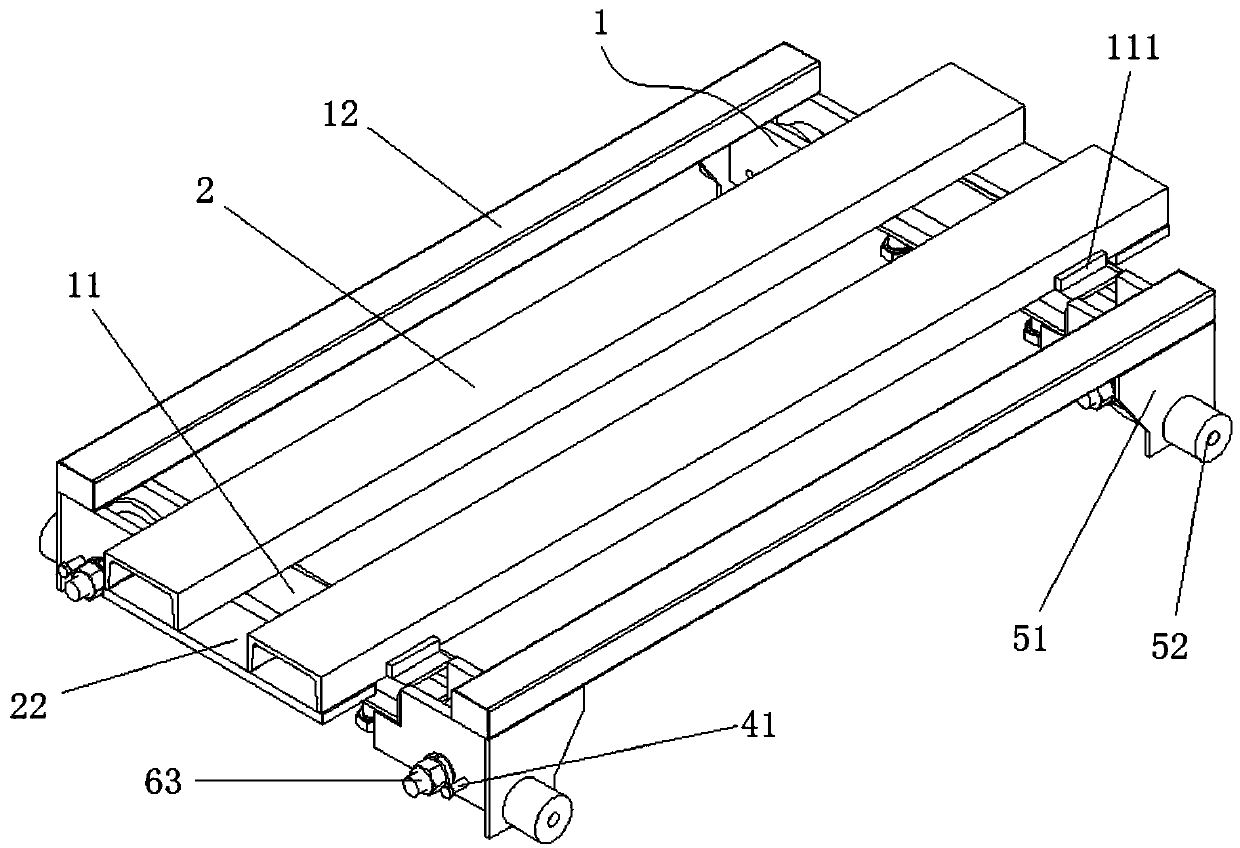

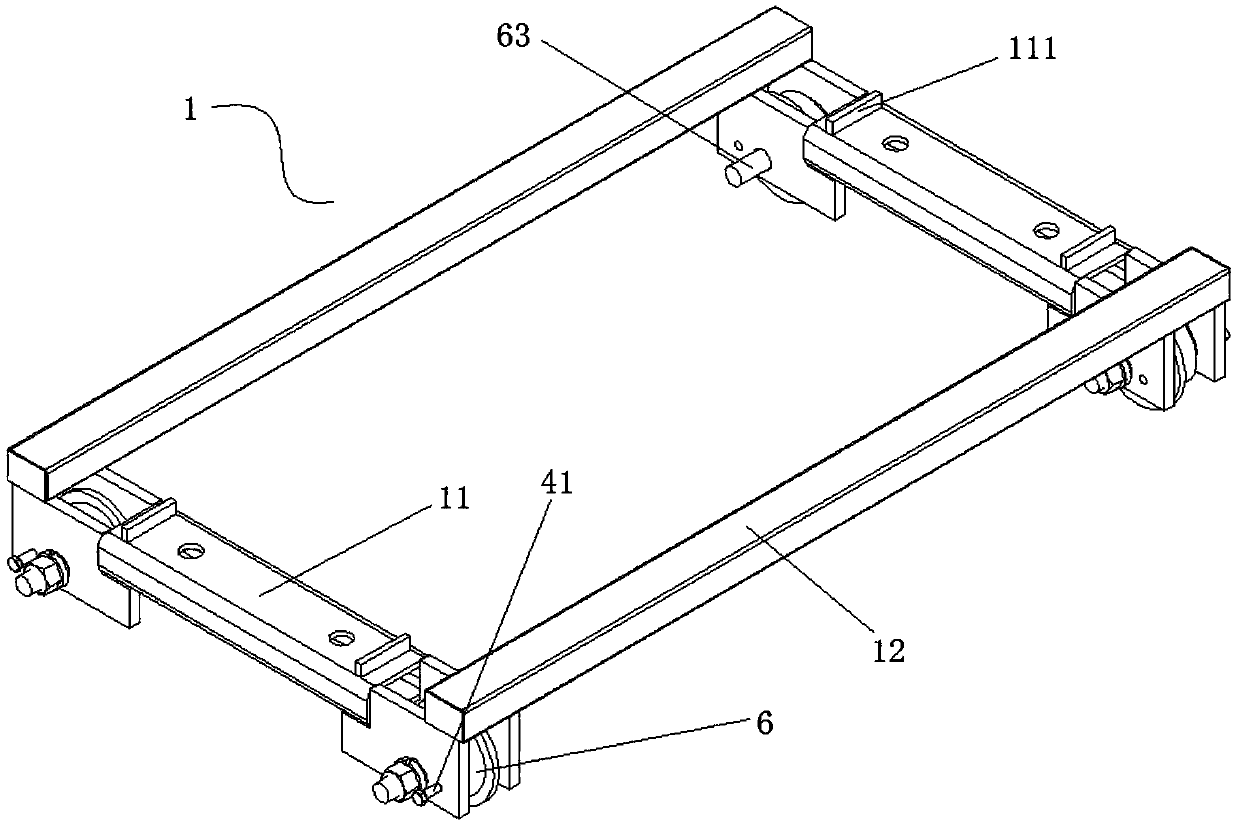

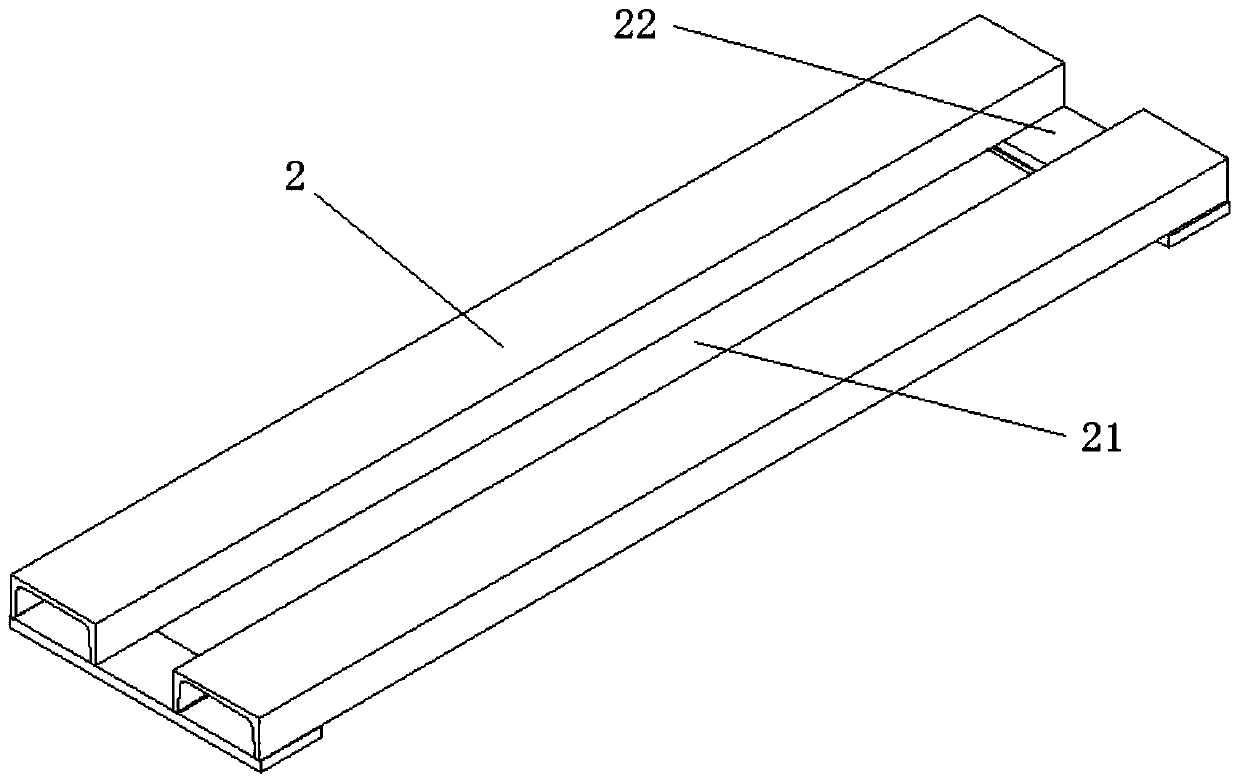

The invention discloses an escalator assembly mobile carrying device which comprises a bearing frame, bearing beams and height adjusting devices. The bottom end of the bearing frame is provided with aplurality of rollers; the at least two bearing beams are arranged, the bearing beams are arranged in a spaced manner to form a limiting slot for carrying an escalator truss, and the bearing beams arearranged at the top end of the bearing frame; and the height adjusting devices are arranged between the bearing beams and the bearing frame so as to be used for adjusting the relative position heightbetween the bearing beams and the bearing frame. The escalator assembly mobile carrying device can realize the movement order of an escalator between all stations, and a crane does not need to be used for hoisting the escalator any more; and balance adjustment of the escalator can be realized very easily, the structure is simple and ingenious, and the manufacturing cost is low.

Description

technical field The invention belongs to the technical field of escalator assembly, and in particular relates to an escalator assembly mobile carrying device. Background technique In order to improve the assembly efficiency of the escalator, in the existing production technology, the assembly production of the escalator mostly adopts the assembly line production mode. However, most of the escalator transfers between stations are still carried out by cranes. This method not only has low work efficiency, but also has potential safety hazards. After each hoisting, it is affected by the unevenness of the ground between stations, which may easily lead to Interference in the debugging of the ladder path of the escalator produces abnormal noise and wear, which affects the service life of the escalator. Contents of the invention In order to solve the above problems, the present invention aims to provide an escalator assembly mobile carrying device, which can realize the moving s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65G35/00B23P19/00

CPCB65G35/00B23P19/001

Inventor 尧刚林振运黄汉钊陈文标

Owner GUANGZHOU GUANGRI ELEVATOR IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com