Tooling for chip cutting experiment and method

A chip and experimental technology, applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of poor manual cutting accuracy, slow speed, high cost, etc. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

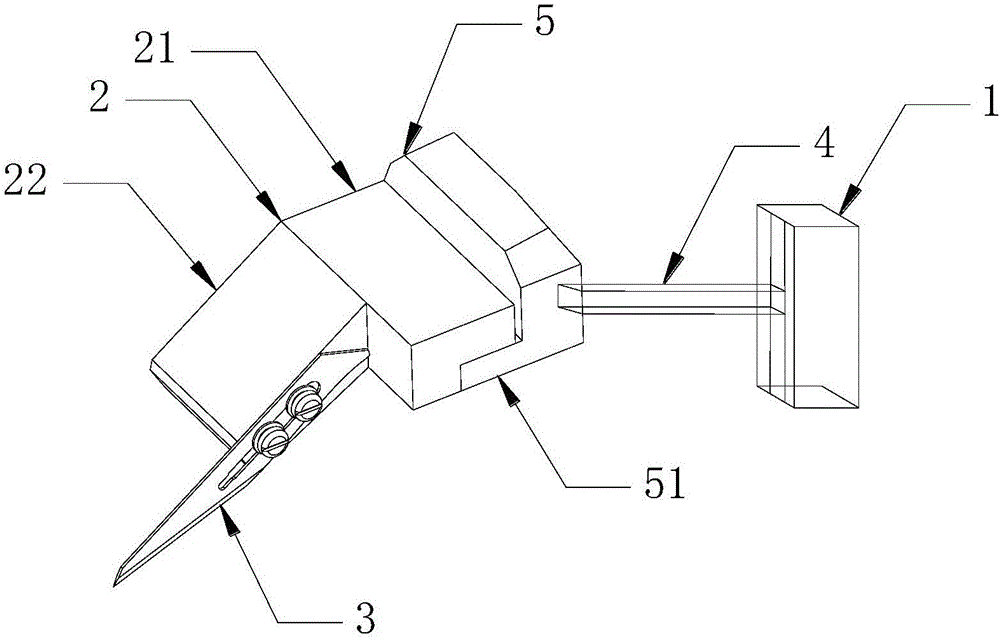

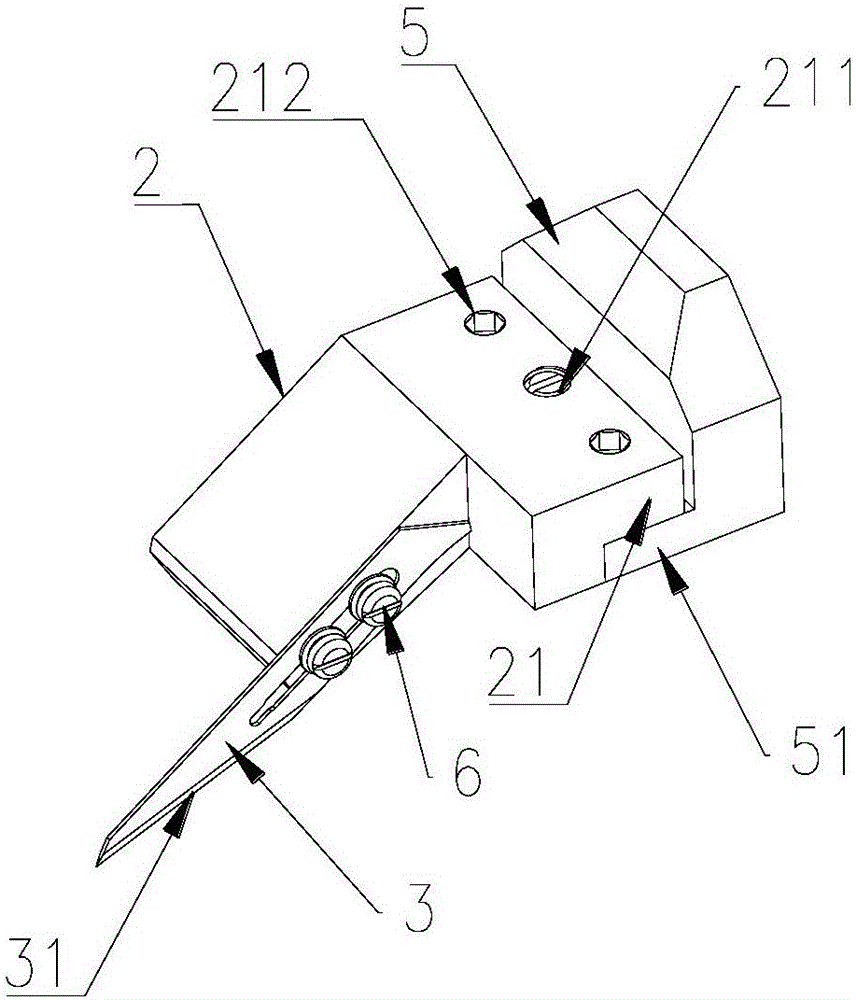

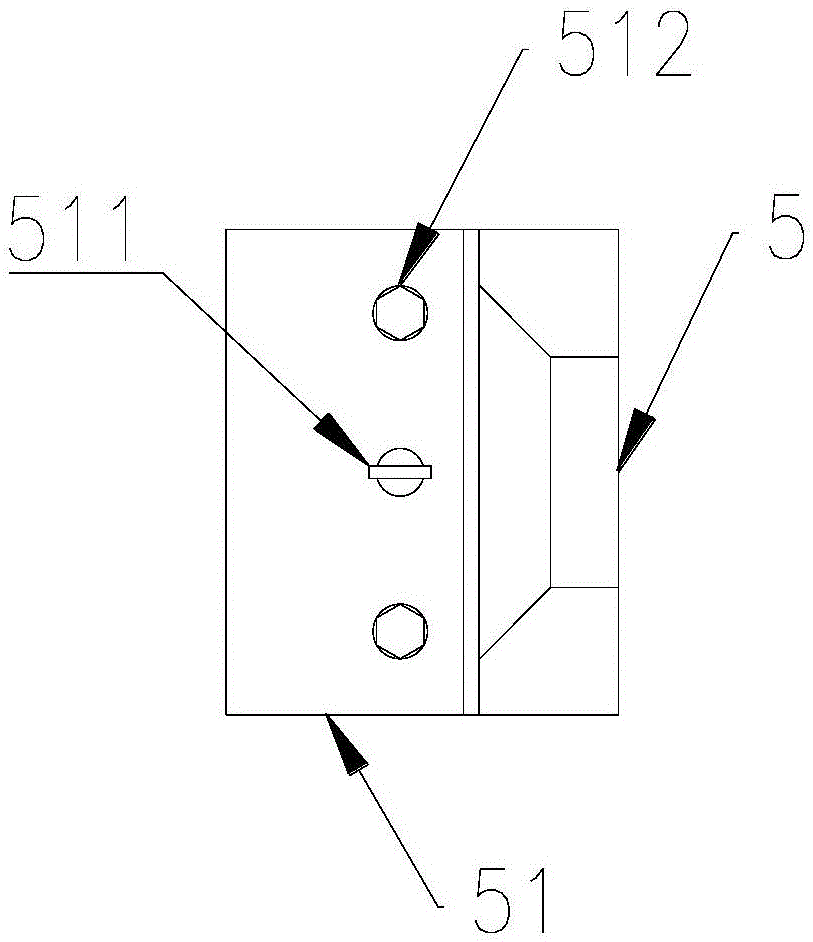

[0033] Such as figure 1 Or as shown in 2, a kind of tooling that is used for the chip cutting experiment of this embodiment, in the chip cutting experiment, the wafer is cut into a chip or the chip is cut, including a microwave probe station, a connector 2 and a cutting blade 3; The probe station includes a base 1 and a mechanical displacement device slidingly connected to the base 1. The other end of the mechanical displacement device is fitted with one end of the connector 2 for driving the connector 2 to move. The cutting blade 3 It is fixedly installed with the other end of the connector 2, and the cutting blade 3 is located above the wafer or chip to be cut.

[0034] The microwave probe station in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com