Automatic brick stacking machine

A brick stacking machine, automatic technology, applied in the direction of stacking, transportation and packaging of objects, can solve the problems of high construction cost, easy to cause shaking, low work efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

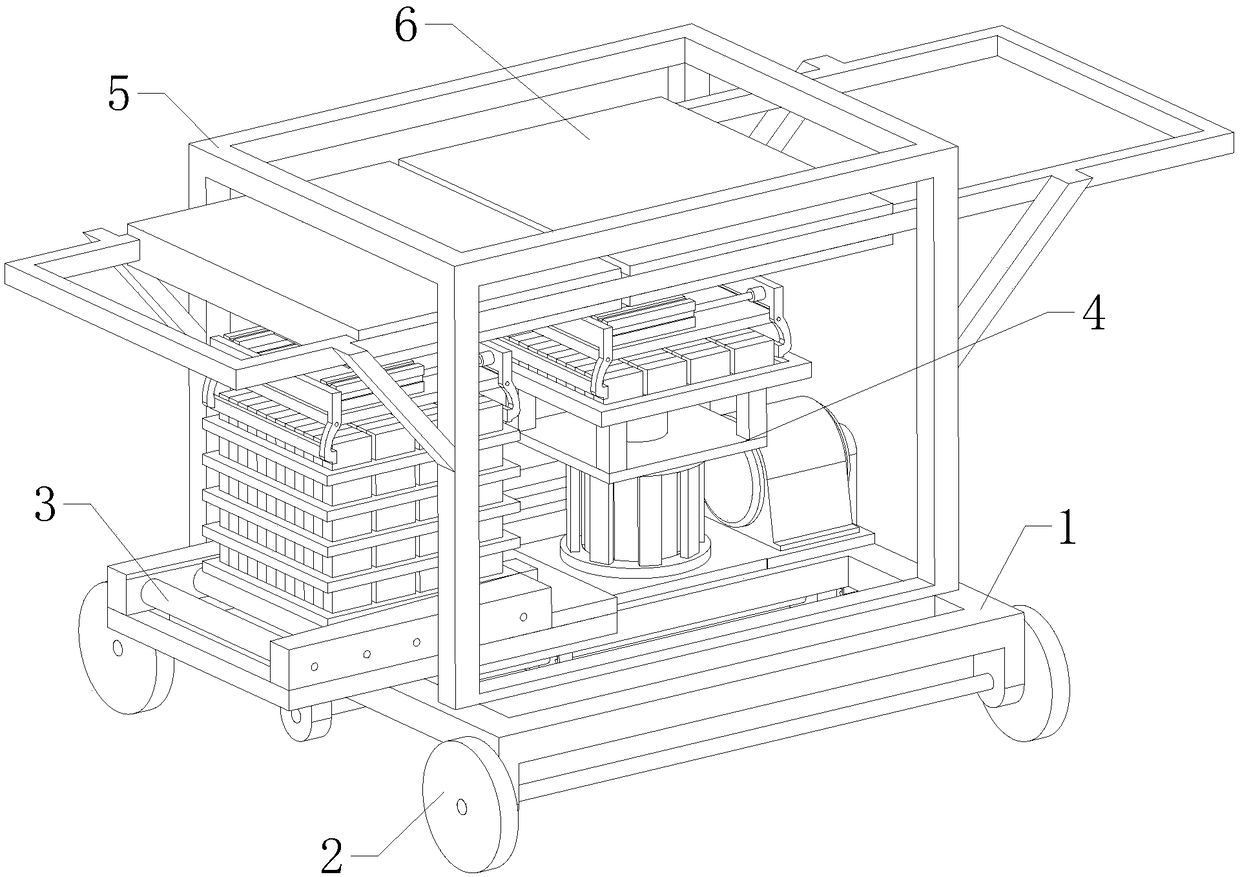

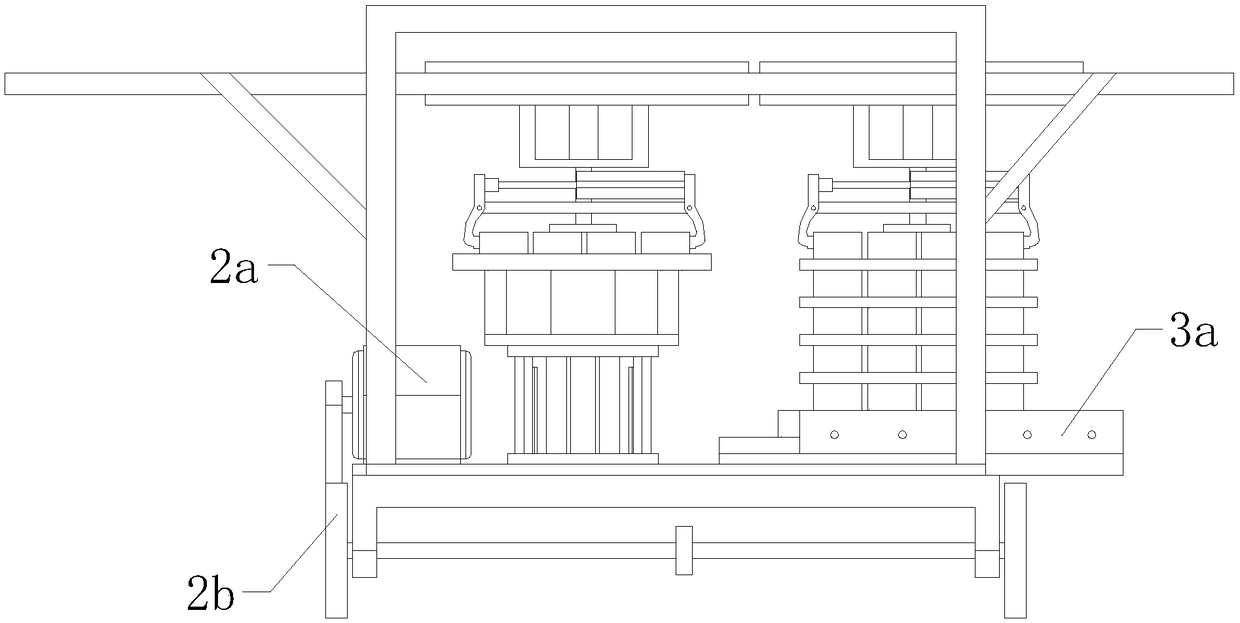

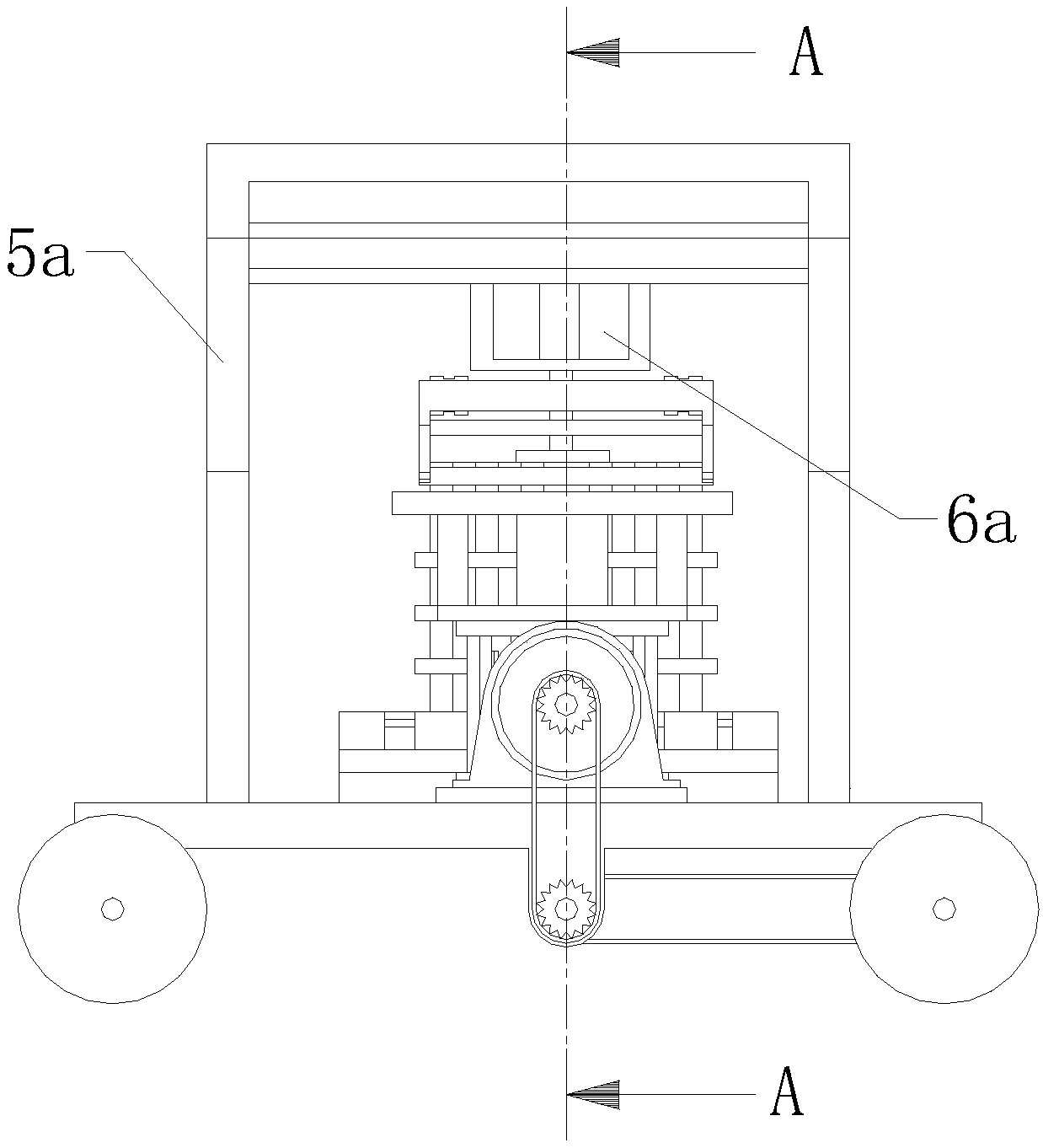

[0029] refer to Figure 1 to Figure 10 The shown automatic brick stacking machine includes a chassis 1, a rolling device 2 arranged on the chassis 1, a brick feeding device 3 arranged on the top of the chassis 1, a brick rotating device 4 arranged on the top of the chassis 1, and a brick rotating device 4 arranged on the top of the chassis. The supporting device 5 on the supporting device 1 and the brick handling device 6 arranged on the supporting device 5, the rolling device 2 includes a driving assembly 2a and a rolling assembly 2b, the driving assembly 2a is fixedly arranged on the top of the chassis 1, and the rolling assembly 2b is rotatably arranged on the bottom of the chassis 1 and is in transmission connection with the driving assembly 2a. The brick feeding device 3 includes a feeding assembly 3a, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com