Carrying trolley of modular unit and using method thereof

A handling trolley, modular technology, applied in the direction of lifting devices, etc., can solve the problems of long handling time, heavy labor, large vibration, etc., and achieve the effects of shortened handling time, high safety, and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

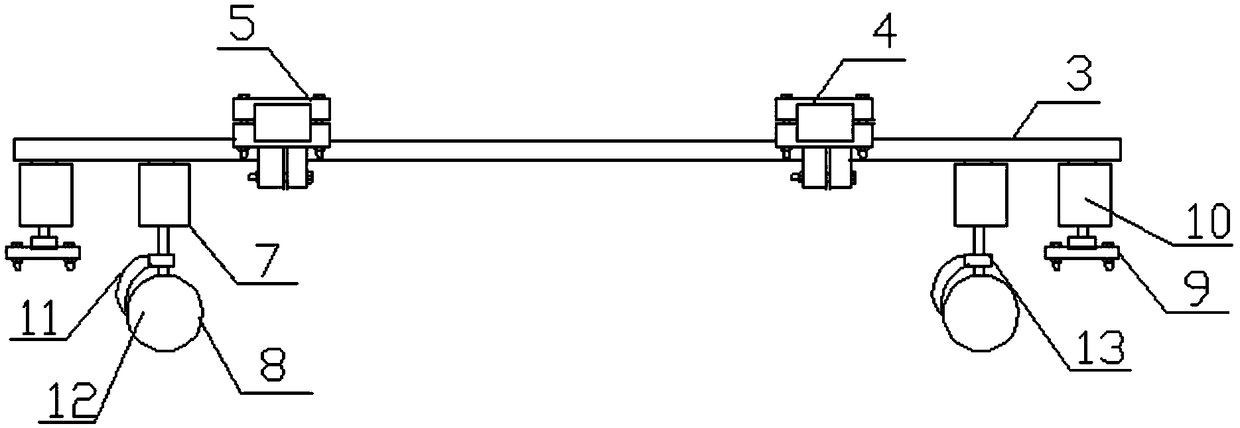

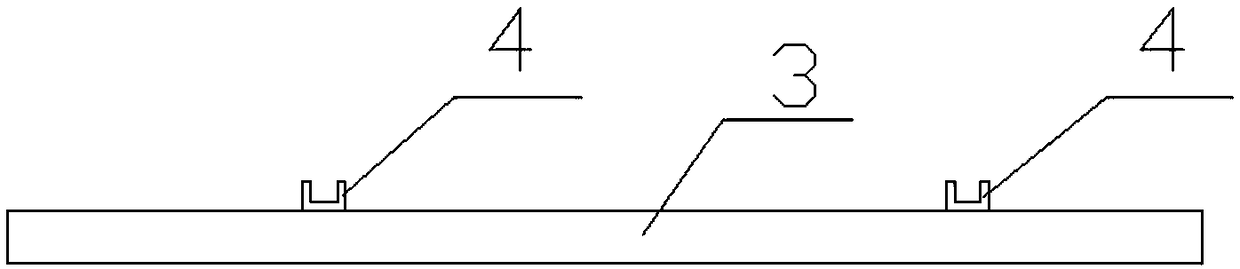

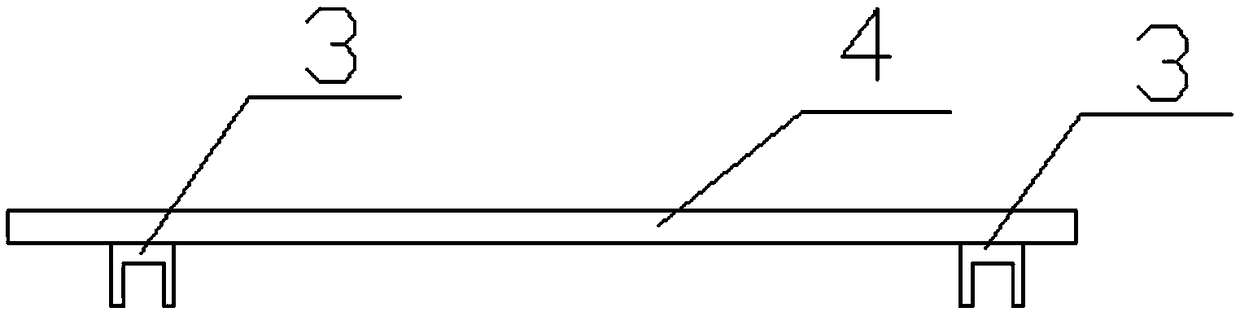

[0033] Example 1: Combining Figure 1 to Figure 4 Illustrate the handling trolley of the modular unit of the present invention, which includes: channel steel frame, four roller hydraulic lifting devices 7, four brake roller groups 8, four trolley temporary fixing devices 9 and four trolley hydraulic lifting devices 10, The channel steel frame is composed of two transverse channel steels 3, two longitudinal channel steels 4 and four special fixing fasteners 5, the two transverse channel steels 3 are arranged in parallel, the two longitudinal channel steels 4 and the two transverse channel steels 3 form a Arranged in a "well" shape, the C-shaped mouth of the longitudinal channel steel 4 faces upward, and the C-shaped mouth of the transverse channel steel 3 faces downward. The special fixing fastener 5 is a commercially available product. The special fixing piece 5 is stuck in the groove of the transverse channel steel 3 or the longitudinal channel steel 4. and one end of the lo...

Embodiment 2

[0035] Embodiment 2: Combination Figure 5 to Figure 7 Illustrate the usage method of the handling trolley of modular unit of the present invention, concrete steps are as follows:

[0036] S1: Assemble the transport trolley as described in any one of claims 1 to 2, and connect the base 1-1 of the unit 1 with the channel steel frame of the trolley through a special hoop 6; the special hoop 6 is similar to a C-shaped steel hoop , fixed by two long bolts;

[0037] S2: When pushing the trolley to transport the unit 1 to the installation position (that is, the position above the equipment base 2), lower the roller hydraulic lifting device 7, and the roller 12 in the braking roller group 8 is fixed on the ground through the brake pad 11;

[0038] S3: Place the unit 1 on the equipment base 2, so that the feet 1-2 on the unit 1 are fixed to the equipment base 2;

[0039] S4: Remove the special hoop 6 to separate the trolley from the unit 1;

[0040]S5: Remove the fixing fastener 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com