A non -slip and wear -resistant ceramics and its preparation methods

A wear-resistant ceramic and anti-skid technology, applied in the field of ceramics, can solve the problems of long use time, insufficient wear resistance, loss of anti-skid, etc., and achieve the effect of short time, good anti-skid function and high wear-resistant coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

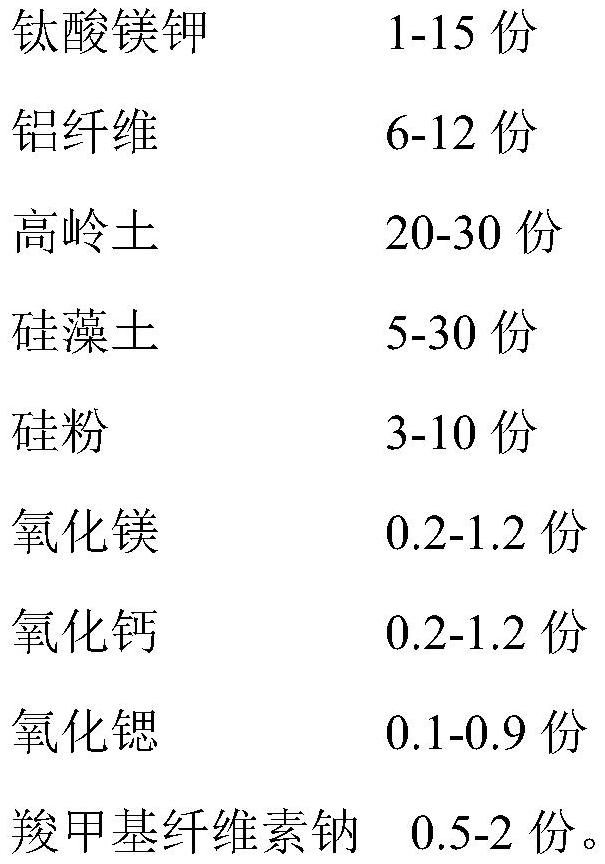

[0028] A kind of antiskid and wear-resistant ceramics, comprising the following components in parts by weight:

[0029]

[0030] The diameter of the aluminum fiber is 20 μm; the silicon powder is 100 mesh; the kaolin and diatomaceous earth are both 150 mesh.

[0031] A preparation method of anti-slip and wear-resistant ceramics, comprising the following steps:

[0032] (1) Weigh each component according to the formula quantity, add potassium magnesium titanate, aluminum fiber, kaolin, diatomaceous earth, silicon powder, and talcum powder into a ball mill and mill for 30 minutes to obtain mixture A;

[0033] (2) Magnesium oxide, calcium oxide, strontium oxide, sodium carboxymethylcellulose, nano-titanium dioxide and 60 parts of water are mixed to obtain mixture B, and then mixture B is added to mixture A, stirred and mixed for 50 minutes to obtain mixture C;

[0034] (3) Dry the mixture C in step (2) at a temperature of 90° C. for 2 hours, and then keep it in a molding mac...

Embodiment 2

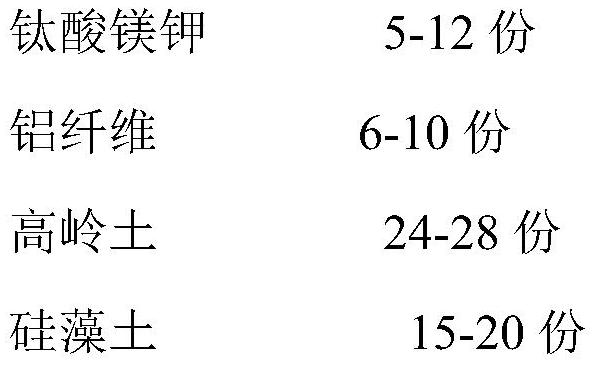

[0039] A kind of antiskid and wear-resistant ceramics, comprising the following components in parts by weight:

[0040]

[0041] The diameter of the aluminum fiber is 23 μm.

[0042] The silicon powder is 150 mesh.

[0043] The mesh numbers of the kaolin and diatomaceous earth are both 90 mesh.

[0044] A preparation method of anti-slip and wear-resistant ceramics, comprising the following steps:

[0045] (1) Weigh each component according to the formula quantity, add potassium magnesium titanate, aluminum fiber, kaolin, diatomaceous earth, and silicon powder into a ball mill and mill for 30 minutes to obtain mixture A;

[0046] (2) Mix magnesium oxide, calcium oxide, strontium oxide, sodium carboxymethylcellulose and 70 parts of water to obtain mixture B, then add mixture B to mixture A, stir and mix for 50 minutes to obtain mixture C;

[0047] (3) Dry the mixture C in step (2) at a temperature of 70° C. for 2 hours, and then keep it in a molding machine at 60 MPa for 1...

Embodiment 3

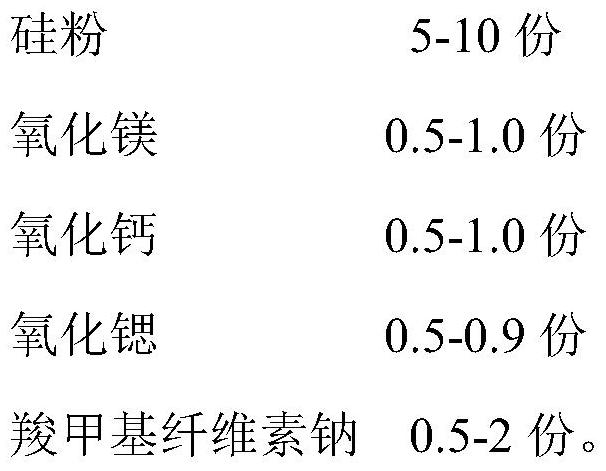

[0052] A kind of antiskid and wear-resistant ceramics, comprising the following components in parts by weight:

[0053]

[0054] Said anti-skid and wear-resistant ceramics also includes 2 parts of talcum powder and 0.8 parts of nano-titanium dioxide in parts by weight.

[0055] The diameter of the aluminum fiber is 25 μm.

[0056] The silicon powder is 150 mesh.

[0057] The mesh numbers of the kaolin and diatomaceous earth are both 100 mesh.

[0058] A preparation method of anti-slip and wear-resistant ceramics, comprising the following steps:

[0059] (1) Weigh each component according to the formula amount, add magnesium potassium titanate, aluminum fiber, kaolin, diatomaceous earth, silicon powder and talcum powder into a ball mill and ball mill for 30 minutes to obtain mixture A;

[0060] (2) Magnesium oxide, calcium oxide, strontium oxide, sodium carboxymethylcellulose, nano-titanium dioxide and 80 parts of water are mixed to obtain mixture B, and then mixture B is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com