A kind of high-purity secondary octanol industrial production method

A production method and high-purity technology, applied in chemical instruments and methods, organic chemistry, preparation of hydroxy compounds, etc., can solve problems such as high-purity secondary octanol, high catalyst requirements, harsh reaction conditions, etc., and achieve easy control , stable product quality, less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

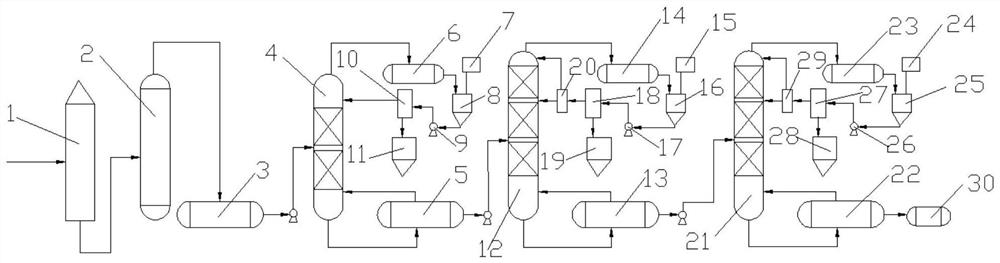

Image

Examples

Embodiment 1

[0023] (1) After the raw material of crude secondary octanol is exchanged by heat exchanger, the entering temperature is 60°C and the acid value is less than or equal to 0.1mg / m 3 Alkali washing tower for alkali washing treatment, and then transported to the standby tank for use;

[0024] (2) Put the raw material processed by alkali washing in the above-mentioned spare tank into the light component rectification tower with a vacuum degree of 70KPa from the middle part feed port, the feed temperature is 110°C, and the light component in the raw material is passed through The light component reboiler connected to the bottom of the tower is vaporized after being heated, and the temperature at the bottom of the tower is 130°C. The vaporized light component returns to the tower through the gas phase inlet, and then flows out from the top of the tower. After the gas is completely condensed by the water cooler, it flows into the reflux tank. The light component liquid in the reflux t...

Embodiment 2

[0028] (1) After the raw material of crude secondary octanol is exchanged in a heat exchanger, the entering temperature is 70°C, and the acid value is ≤0.1mg / m 3 Alkali washing tower for alkali washing treatment, and then transported to the standby tank for use;

[0029] (2) Put the raw material processed by alkali washing in the above-mentioned spare tank into the light component rectification tower with a vacuum degree of 75KPa from the middle part feed port, the feed temperature is 115 ° C, and the light component in the raw material is passed The light component reboiler connected to the bottom of the tower is heated and then vaporized. The temperature at the bottom of the tower is 135°C. The vaporized light component is returned to the tower through the gas phase inlet, and the gas and liquid are exchanged in the stripping section and the rectifying section. Then it flows out from the top of the tower, the temperature at the top of the tower is 80°C, the light component g...

Embodiment 3

[0033] (1) After the crude secondary octanol raw material is exchanged by a heat exchanger, the temperature of entry is 80°C, and the acid value is ≤0.1mg / m 3 Alkali washing tower for alkali washing treatment, and then transported to the standby tank for use;

[0034] (2) Put the raw material processed by alkali washing in the above-mentioned spare tank into the light component rectification tower with a vacuum degree of 80KPa from the middle part feed port, the feed temperature is 120°C, and the light component in the raw material is passed through The light component reboiler connected to the bottom of the tower is heated and then vaporized. The temperature at the bottom of the tower is 140°C. The vaporized light component is returned to the tower through the gas phase inlet, and the gas and liquid are exchanged in the stripping section and the rectifying section. Then it flows out from the top of the tower, the temperature at the top of the tower is 85°C, the light componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com