A kind of method for preparing 2,2-dimethoxypropane

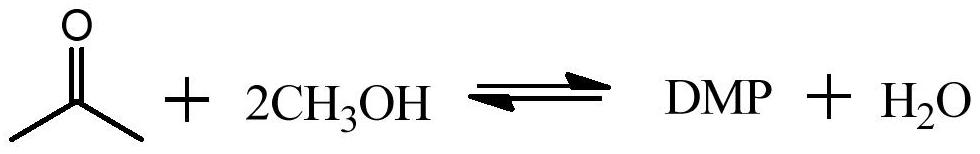

A dimethoxypropane, methanol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as cumbersome operations, simplify the process, avoid low-temperature operation or the use of dehydrating agents, avoid The effect of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

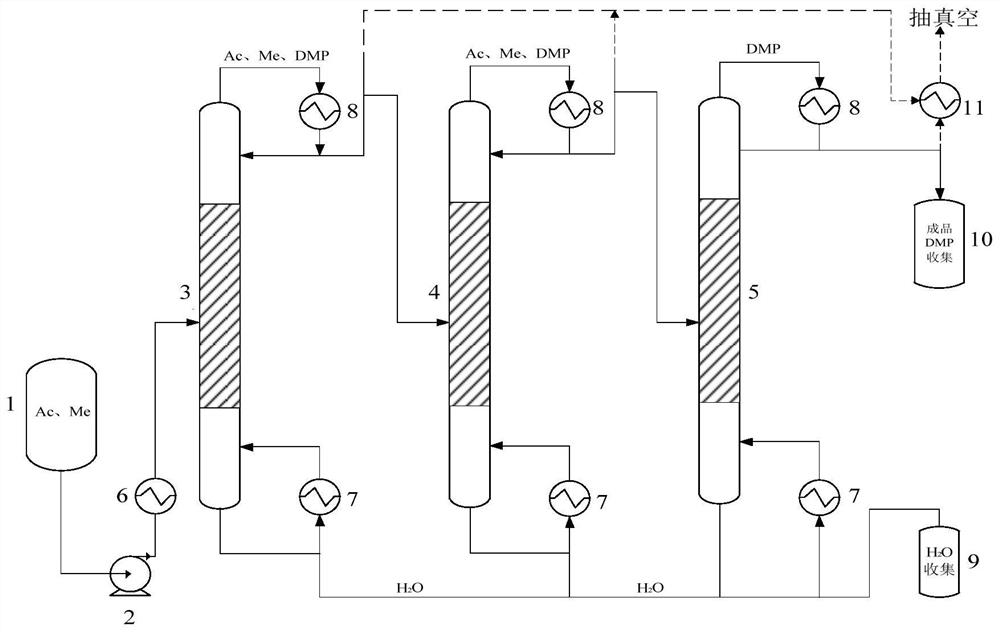

[0033] Such as figure 1 As described, the tower reactor includes a raw material tank 1, a raw material pump 2, a first plate rectification tower 3, a second plate rectification tower 4, a third plate rectification tower 5, a feed heat exchanger 6, and a tower still Boiler 7, tower top condenser 8, tower bottom water collection tank 9, product collection tank 10 and emptying condenser 11. Wherein, the first plate rectification tower 3, the second plate rectification tower 4 and the third plate rectification tower 5 are connected in series in sequence. The raw material tank 1 stores the mixed solution of methanol and acetone, which is sent to the first plate rectifying tower 3 through the raw material pump 2 through the feed heat exchanger 6 for condensation reaction, and the mixture fraction generated by the reaction is condensed by the tower top condenser 8, It enters the second plate rectification tower 4 again from the top of the tower, and part of the mixture fraction is r...

specific Embodiment

[0035] The height of the plate distillation tower is 1.5m. The reaction tower is filled with strongly acidic styrene-based cation exchange resin, and the mixture of acetone and methanol (molar ratio = 1:2) enters the 1.5m tower from the side line (0.3m tower height). Inside, the feed flow rate is 1.25 mol / h in terms of methanol in the components. The overhead distillate is used as the feed to the next column to continue the reaction. Three identical columns are connected in series (total plate number N≈50×0.8×3=120, which is greater than the minimum theoretical reaction plate number N under the temperature and pressure min =113), control the pressure in the first tower successively to be 2.0kPa, the tower still temperature is 18°C, the reflux ratio R=0.6, the second tower inner pressure is 1.2kPa, the tower still temperature is 10°C, the reflux ratio R= 0.8, the pressure inside the third tower is 700Pa, the temperature of the bottom of the tower is 2°C, and the reflux ratio R...

Embodiment 2

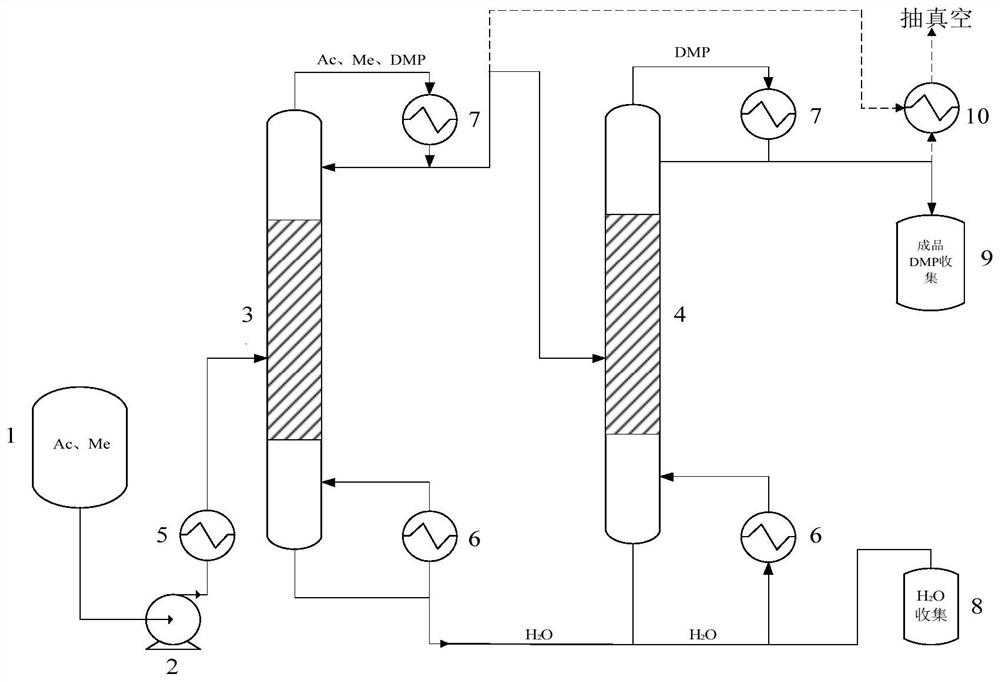

[0038] Such as figure 2Said, the tower reactor comprises raw material tank 1, raw material pump 2, first plate rectification tower 3, second plate rectification tower 4, feed heat exchanger 5, tower still reboiler 6, tower top condenser 7. Tower kettle water collection tank 8, product collection tank 9 and emptying condenser 10. Wherein, the first plate rectification tower 3 and the second plate rectification tower 4 are connected in series. The raw material tank 1 stores the mixed solution of methanol and acetone, which is sent to the first plate rectification tower 3 through the raw material pump 2 through the feed heat exchanger 5 for condensation reaction, and the mixture fraction generated by the reaction is condensed by the overhead condenser 7, It enters the second plate rectification tower 4 again from the top of the tower, and part of the mixture fraction is refluxed in the first plate rectification tower 3 . The water generated by the reaction enters the water col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com